Industrial Machinery

Power & Drive Unit

Engines (Diesel & Gas)

Wide variety of engines for power generation, marine and on-board use, supporting daily life

Compressors & Mechanical Turbines

Air and gas ompressors necessary for manufacturing, steam turbines for driving, etc.

Hydraulic Components

Hydraulic machines that support a wide range of industries and livelihoods through hydraulic and control technologies as test equipment and drive sources for marine machinery

Manufacturing & Production Equipment

Printing Machinery

State-of-the-art printing machines that support businesses with reliability and productivity

Paper Converting Machinery

World-class paper converting machinery that support the manufacturing of corrugated cardboard and boxes

Metals Machinery

Metals machinery for steelmaking plants (hot and cold rolling equipment, high value-added process equipment, etc.)

Storage Tanks & Gas Holder

Variable gas holders that respond to changes in the volume of by-product gas in iron lworks

Food & Packaging Machinery

Food-related machinery such as beverage/pouch filling machines, and liquid processing equipment

Testing & Research Facilities

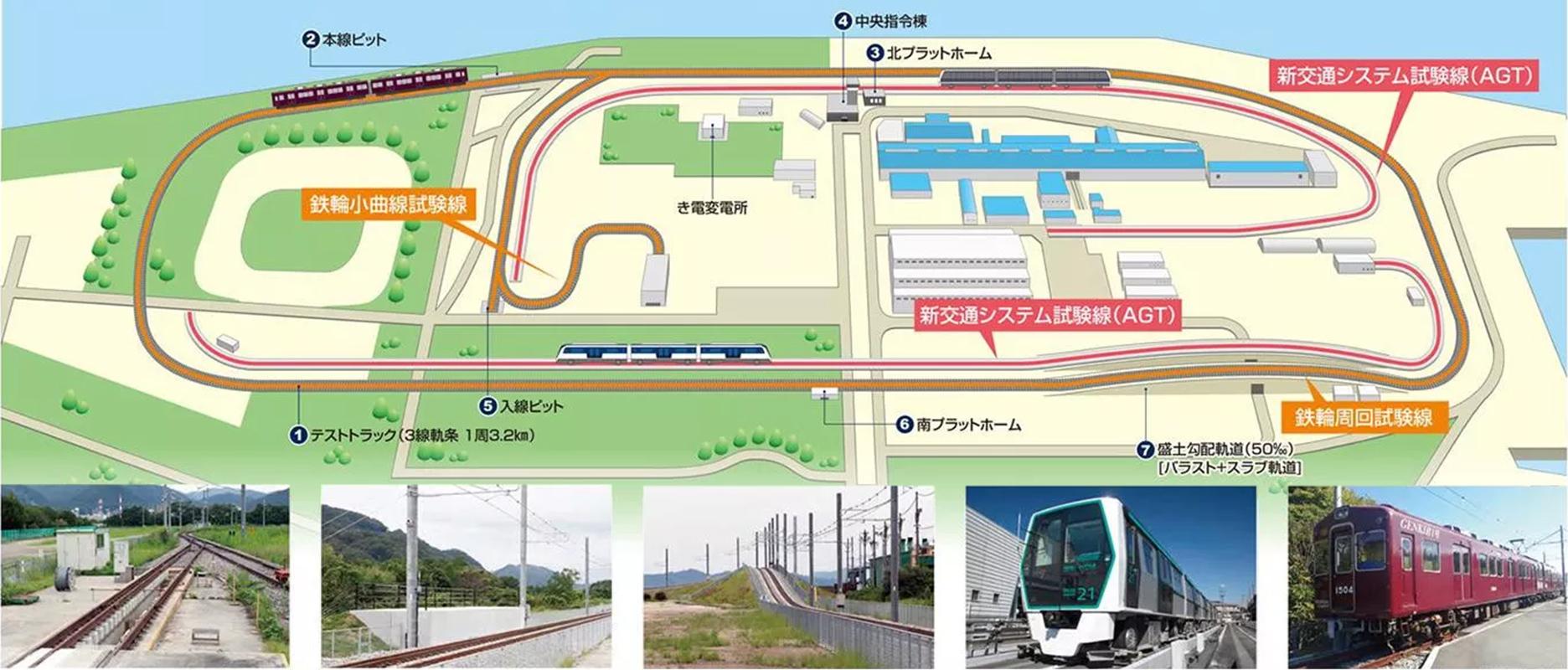

Urban Mobility Railway System Testing Facility

Testing equipment and facilities for urban mobility railway systems

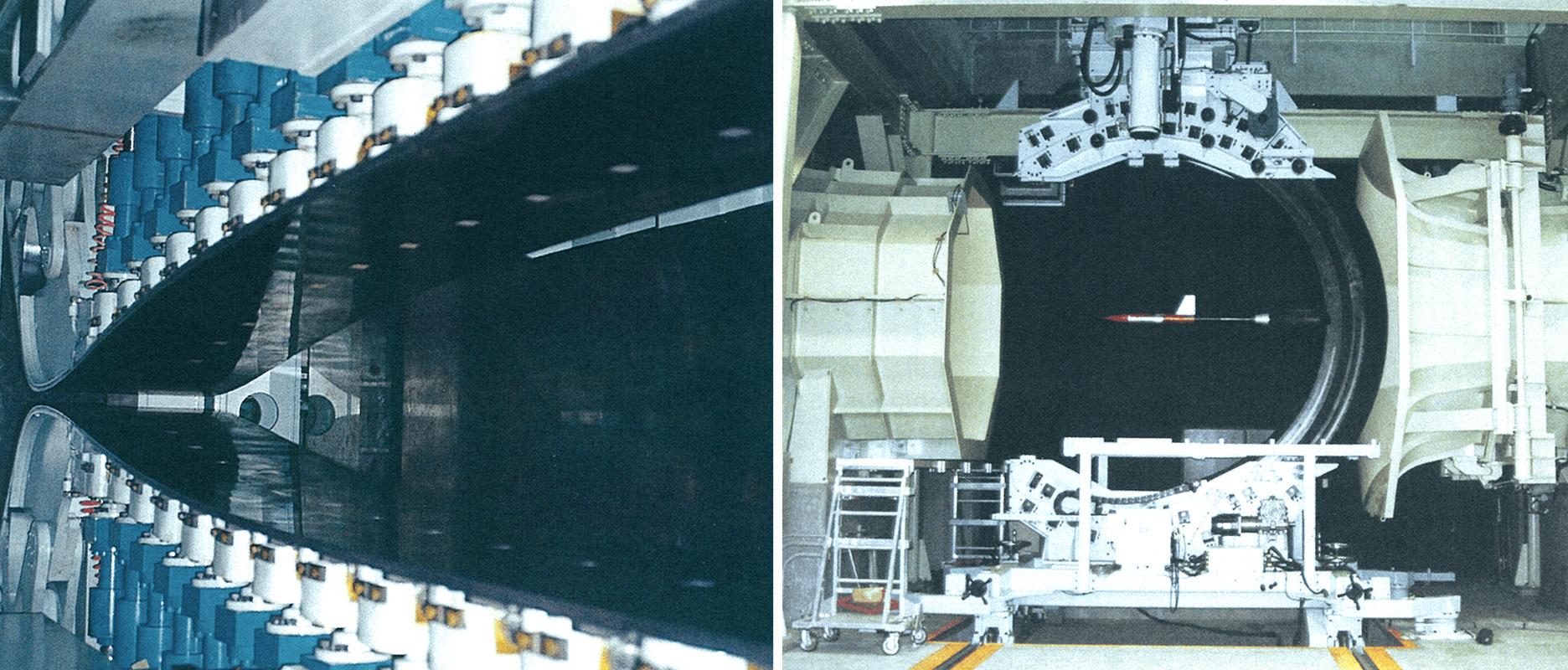

Aerospace Testing Facility

Testing equipment and facilities supporting aerospace research and development

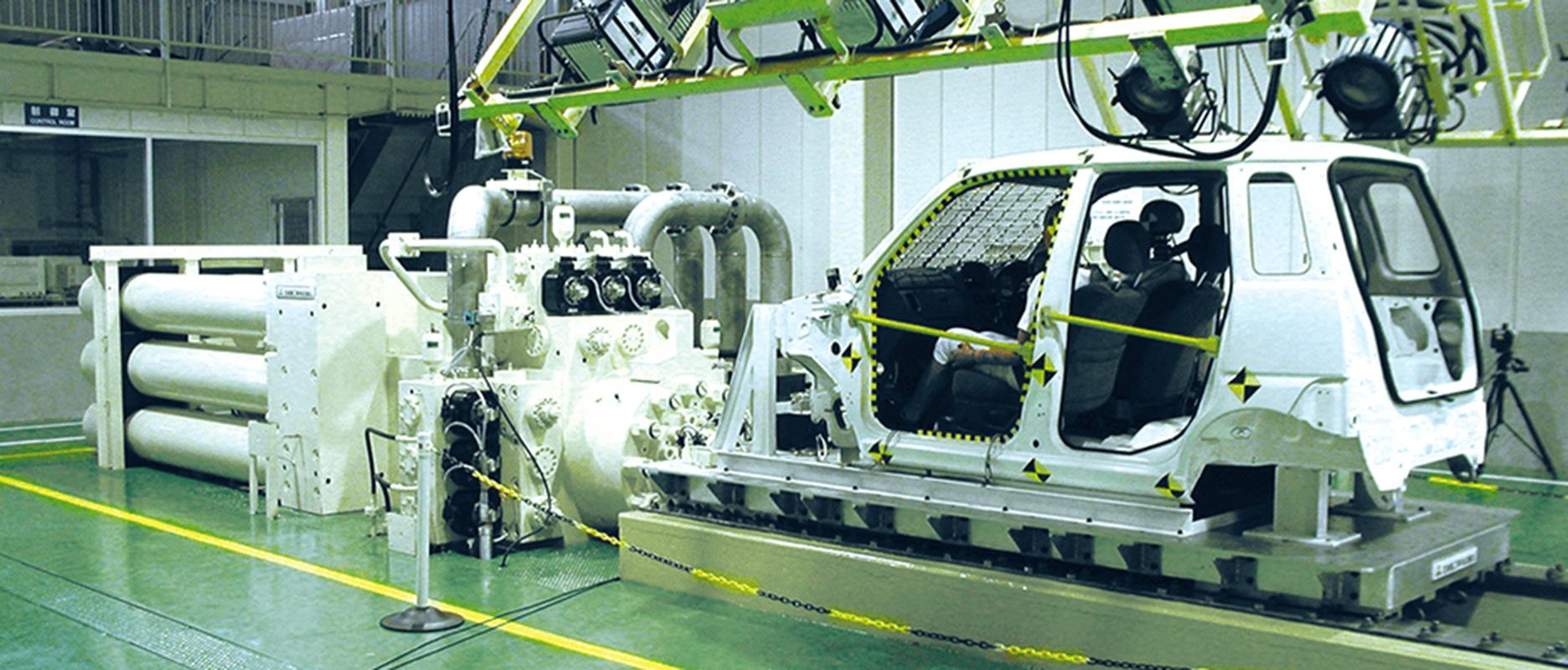

Testing Facility for Construction & Civil Structures

Testing equipment and facilities for verifying the safety, durability and reliability of civil construction structures

Artificial Weather & Insolation Test Facility

Artificial weather and solar radiation environment testing equipment and facilities for weatherability/performance testing

Acoustic Testing Facility

Testing facilities for acoustic testing in various sound environment such as underwater

Particle Accelerators & Nuclear-related Testing Facility

Testting equipment and facilities for advanced testing and evaluation in the fields of nuclear power and advanced science

Business Infrastructure & Equipment

Industrial IT Solutions

Security measures for industrial control systems and explosion-proof monitoring systems for power plants

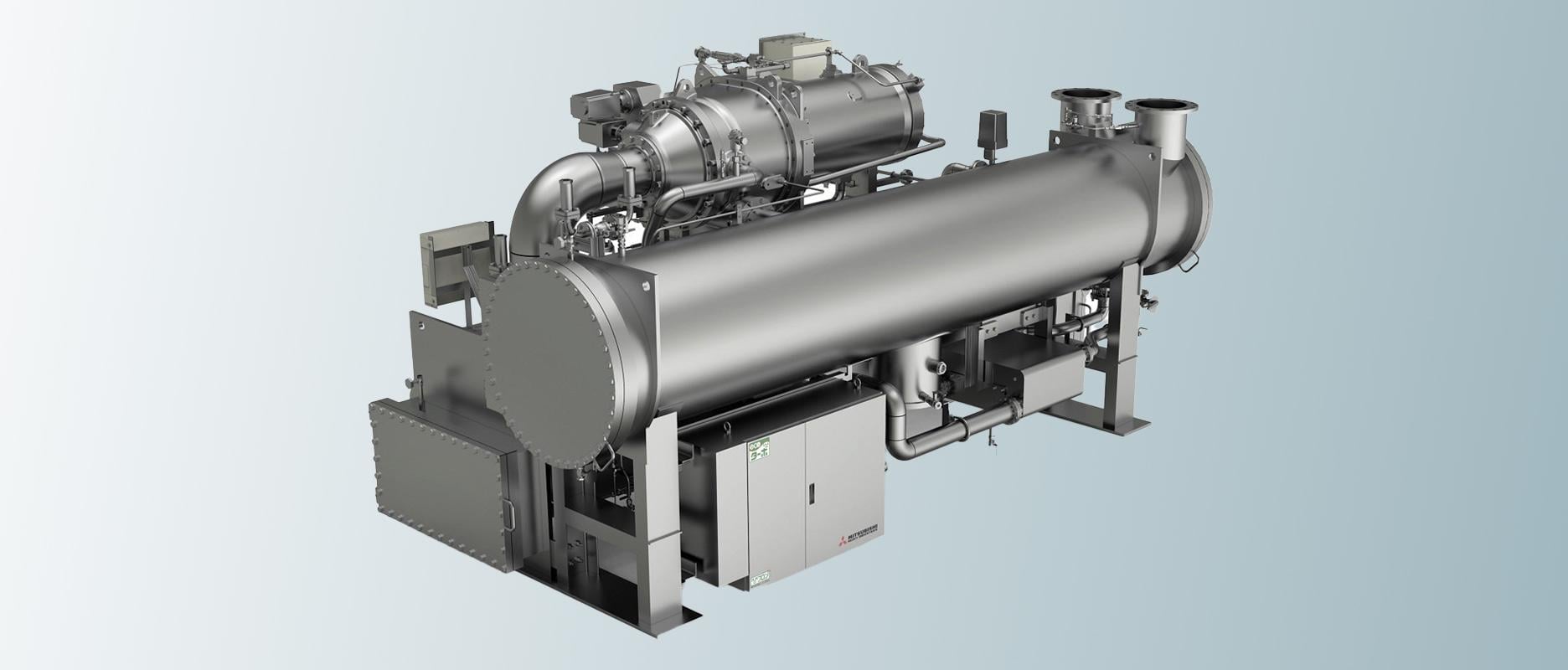

Industrial AC Equipment & Centrifugal Chillers

Commercial air conditioners and chillers for large-scale facilities offering energy-saving and comfort

Piping & Pumps

Power station hydraulic iron pipes, circulating water pipes, tubing tanks and process industry pumps

Logistics & Material Handling

Logistics & Material Handling Equipment such as forklift and carrier systems

Plant Engineering

Chemical Plants

Construction of chemical plants, including fertilizer, methanol, and petrochemical plants