Liquid Lithium Test Loop

A Key Facility for the Development of the Nuclear Fusion Prototype Reactor

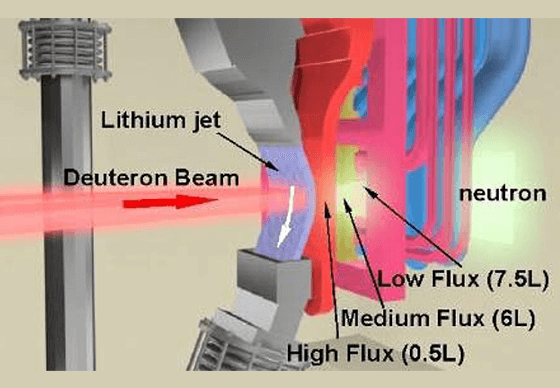

This is a facility to validate target equipment in an accelerator when accelerating a deuteron beam into lithium to generate neutrons (liquid lithium target). The accelerator experiments are conducted as Engineering Validation and Engineering Design Activities (EVADA) at the International Fusion Material Irradiation Facility (IFMIF).

Toward the Realization of a Fusion Prototype Reactor

Researchers from around the world are collaborating in engineering validation and design activities to construct an International Fusion Material Irradiation Facility (IFMIF) to be used for the development and testing of materials for a fusion prototype reactor (the IFMIF/EVEDA Project).

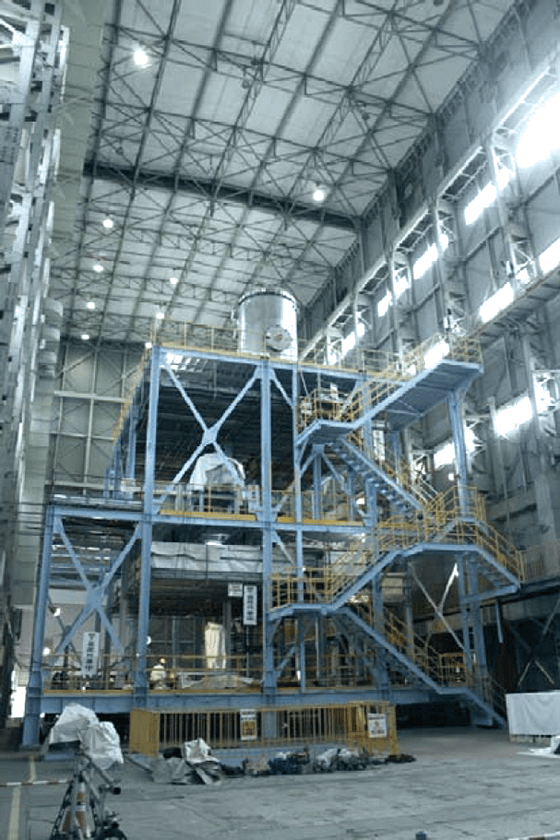

In one validation activity, the liquid lithium test loop is used to evaluate the integrity of the lithium target, the emission source of neutrons for material irradiation.

The validation test assesses the stability of a high-speed flow of 20 m per second and the long-period integrity of the lithium loop (including safe continuous operation). The test is executed simultaneously with the lithium refinement required for the long-period integrity of lithium devices, etc.

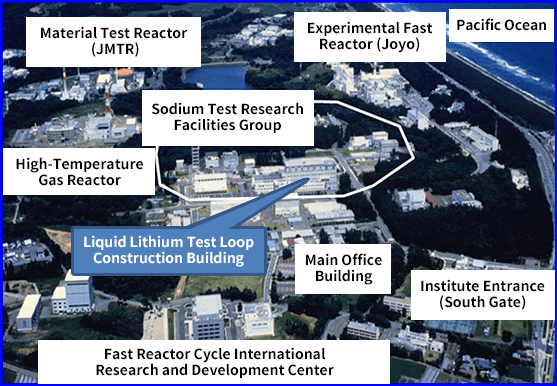

This loop will be constructed at the Oarai Research & Development Institute, a research center with almost 40 years of experience with the technologies used to handle sodium (coolant for fast breeding reactor) [a: and liquid metals like lithium] [b: liquid metals like lithium] [c: NEW].

Main Specifications of the Liquid Lithium Test Loop

Slide horizontally to see the table.

| Main constituent material of the loop | Stainless steel (SUS304) | |

|---|---|---|

| Amount of lithium handled (held) | 2,500kg (Approximately 5m3) | |

| Design / maximum allowable working temperature | 400°C/350°C | |

| Normal operating temperature | 250°C to 300°C | |

| Flow rate (maximum) | 3,000L/min | |

| Flow speed | Main pipe (6B) | <3m/sec |

| Target assembly | to 20m/sec | |

| Safety countermeasures | Equivalent to sodium test equipment | |

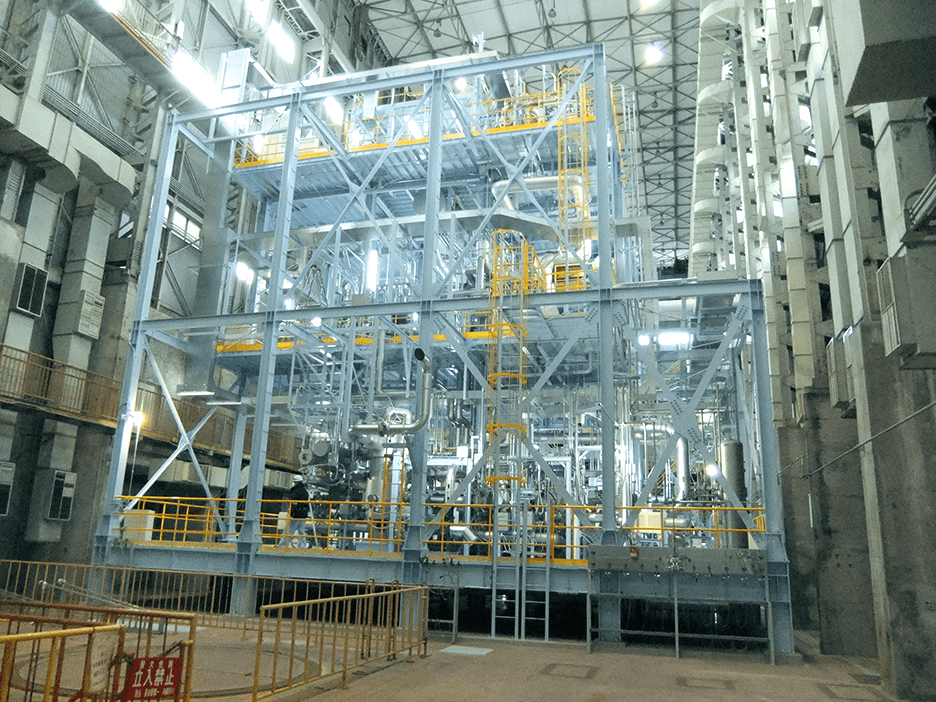

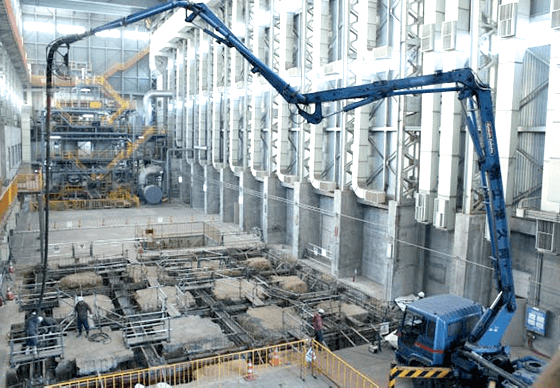

Construction Status

Slide horizontally to see the table.

| Nov, 2, 2009 | Start of construction work |

|---|---|

| Dec, 02, 2009 | Start of underground pile driving |

| Dec, 24, 2009 | Pouring of base concrete |

| Jan, 18, 2010 | Completion of the frame foundation (floor mold) |

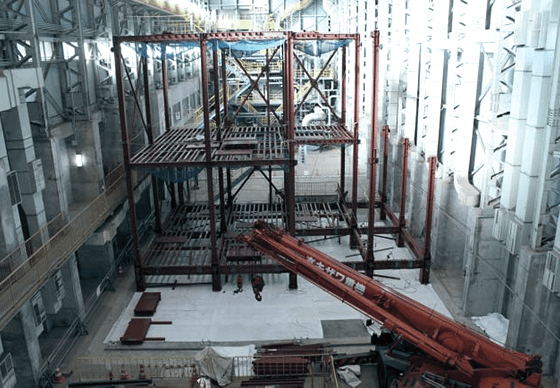

| Jan, 21, 2010 | Start of stand frame installation |

| Mar, 16, 2010 | Start of power supply facility installation |

| Mar, 19, 2010 | Completion of the loop frame |

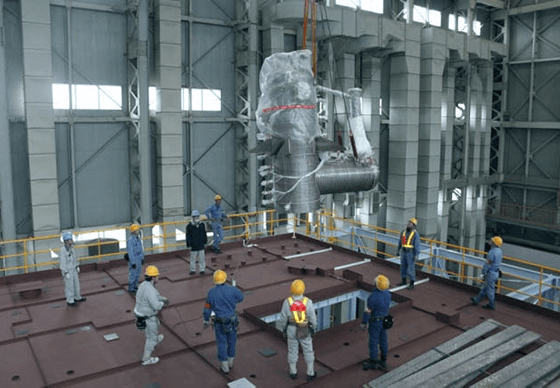

| March 26, 2010 | Start loop component installation |

| Apr, 27, 2010 | Start of pipe connection |

Distributors :