EX ROVR "ASCENT", the autonomous, explosion-proof, plant inspection robot : News

EX ROVR "ASCENT", the autonomous, explosion-proof, plant inspection robot : News

News

- NEWEX ROVR "ASCENT" Showcased at the SPRINT Robotics World Conference for Inspection & Maintenance Robotics 2025

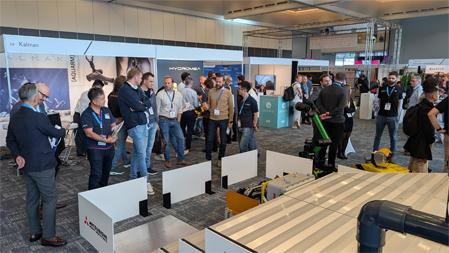

Continuing our participation from last year, EX ROVR "ASCENT" was proudly showcased at the SPRINT Robotics World Conference for Inspection & Maintenance Robotics 2025, held in Amsterdam from October 20th to 22nd. Celebrating its 10th anniversary this year, the conference attracted over 550 participants from more than 35 countries, featuring more than 60 exhibition booths and 50+ internationally renowned robotics experts delivering insightful presentations. This event has firmly established itself as one of the world's largest and most prestigious gatherings for inspection and maintenance robotics.

At our booth, we demonstrated autonomous inspection capabilities of EX ROVR “ASCENT”, including lever operation using its manipulator (robotic arm) and stability tests simulating use on FPSOs (Floating Production, Storage and Offloading system). Additionally, we partnered with Energy Robotics, a Germany-based software company providing the leading in AI software platform for autonomous inspection, to co-host a booth where we showcased a live demonstration of EX ROVR "ASCENT" integrated with their software solution. This collaboration provided attendees with a firsthand experience of how system integration can expand the future potential of robotic applications.

Through this year's exhibition, we believe attendees gained a deeper understanding of the continued evolution of EX ROVR "ASCENT." Moving forward, EX ROVR "ASCENT" will continue to be a key player in solving a variety of challenges for our customers, including increasing plant inspection efficiency, reducing human labor, enhancing safety, and improving operational uptime.

(note: Energy Robotics is the leading AI-powered SaaS platform for automating operations and unmanning industrial infrastructure with robots and drones.)

https://conference.sprintrobotics.org/

- EX ROVR "ASCENT" Trial completed at a Thermal Power Plant in Singapore

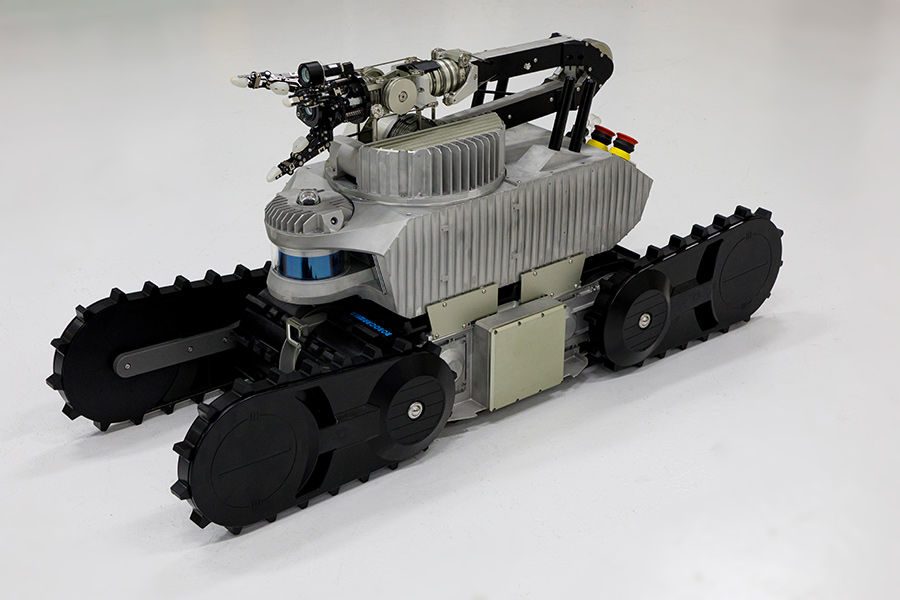

Mitsubishi Heavy Industries, Ltd. (MHI) successfully concluded a two-month trial at a Thermal Power Plant in Singapore which occurred from February to March 2025. Throughout this period, execution of multiple complex robot tasks and activities were conducted to demonstrate the manipulation and autonomous capabilities of EX ROVR. These activities included staircase ascension/descension, automated mapping, and autonomous data collection during automatic patrols to name a few.

The trial results demonstrated EX ROVR's mobility superiority and wide range of motions due to its multi-purpose 6-axis manipulator. Given EX ROVR's compact platform, narrow and close-quarter navigation was repeatedly proven which further demonstrated EX ROVR's advantageous capabilities.

The learnings from this effort will allow MHI to further improve usability and enhance the functionality of EX ROVR by considering the customer's requests and feedback. These efforts further solidify that MHI's EX ROVR will remain the most reliable robotic platform and partner for end-users.

- EX ROVR "ASCENT" Testing completed at TotalEnergies' TADI site.

TotalEnergies and Mitsubishi Heavy Industries (MHI) have successfully concluded a three-month trial at TADI (TotalEnergies Anomaly Detection Initiatives) site in Lacq, France. Throughout this period, extensive tests were conducted on manipulation and autonomous capabilities of EX ROVR, including stair navigation and autonomous control panel operation.

As expected, the extensive use of the integrated 6-axis state-of-the-art manipulator at the TADI site confirmed the potential to carry out remote operations safely in line with TotalEnergies future operational model.

Because of EX ROVR's unique features and its ATEX and IECEX Zone 1 certifications, our technology can clearly contribute to the safe operation of industrial sites.

MHI remains committed to listening to acquired customer feedback to further enhance EX ROVR, with the ultimate expectation of delivering greater value for both onshore and offshore assets, all while ensuring safer and more efficient operations.

- EX ROVR "ASCENT" exhibited at the 2024 SPRINT Robotics World Conference for Inspection & Maintenance Robotics

EX ROVR "ASCENT" was exhibited at the "SPRINT Robotics World Conference for Inspection & Maintenance Robotics 2024", the world's largest exhibition of maintenance inspection robots, held in Antwerp, Belgium on October 29-30, 2024. At the exhibition, many companies demostrated their robotic technologies related to performing of maintenance and/or inspections. This conference demostrated a common pursuit by industry and academia to advance technologies that can safely and predicabilty perform a variety of tasks at oil and gas assets.

Our exibition booth was visited by experts from a variety of industries, specifically oil and gas and chemical industries. Since an EX ROVR "ASCENT" was present, everyone was able to see our explosion-proof certified robot climbing stairs using its crawlers and demonstrating a simulation of a plant restart operation using an advanced 6-axis manipulator that enables delicate movement. Additionally, we took advantage of the this opportunity to speak at the conference where we discussed EX ROVR's ability to operate safely at various proof of concepts, internal research efforts, and results from recently completed trial operations at oil and gas assets.

All visitors and interactions held during this conference facilitated a forum where we could dicuss the value EX ROVR "ASCENT" can bring to various industries and end-users; such as, performance of inspections, emergency first responder, and manipulator tasks. At Mitsubishi Heavy Industries, Ltd., we remain committed to ensuring our technologies bring the greatest value to end-users and support our customers' needs.

- Positive YNOW2024 Conference Experience for EX ROVR "ASCENT"

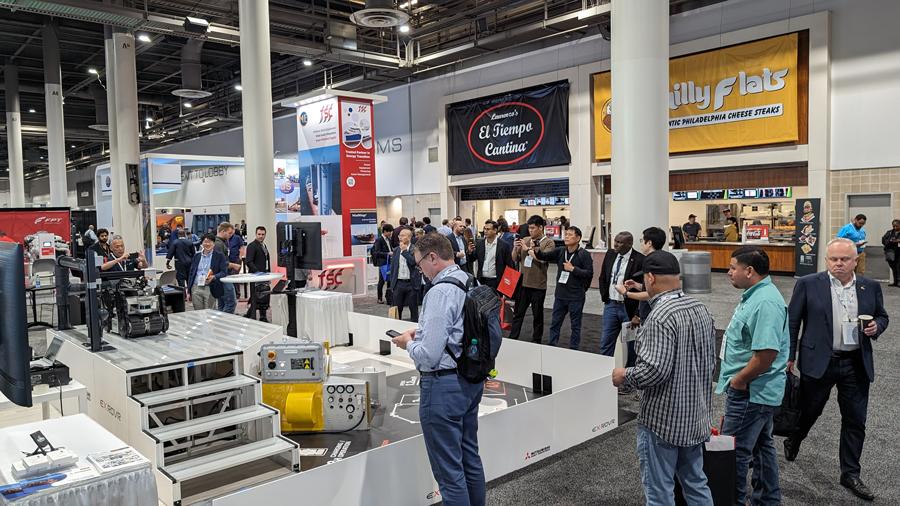

MHI recently concluded a successful participation at the YNOW2024, YOKOGAWA Users Conference, held in Houston, Texas from October 28-30, 2024. In collaboration with YOKOGAWA, EX ROVR "ASCENT" was utilized to demonstrate that MHI's robotic technology, along with other robotic technology providers, can be easily integrated and operated from YOKOGAWA's fleet management software OpreX Robot Management Core (RMC). This demonstration was met with excitement and resulted in many positive interactions with representatives from multiple industries as it shows a positive step toward wider robotic technology adoption, along with data collection, management, and assessment. Additionally, MHI was a speaker on the "Robotics for the Process Industry" panel where we provided our perspective on the value robotics can bring end-users, but also provided a holistic view on the roadmap to ensure wider adoption.

YNOW2024: A Yokogawa Users Conference | Yokogawa America

OpreX Robot Management Core | YOKOGAWA

- EX ROVR "ASCENT" Exhibition at the 2024 SPRINT Robotics World Conference for Inspection & Maintenance Robotics

EX ROVR "ASCENT" will be exhibited at the 2024 SPRINT Robotics World Conference for Inspection & Maintenance Robotics, October 29-30 in Antwerp, Belgium. The Conference is one of the world's largest maintenance and inspection robot exhibitions with more than 60 exhibition booths and lectures by more than 50 internationally recognized robotic professionals.

As is typically done at our exhibitions, EX ROVR "ASCENT" will demonstrate its ability to perform automatic inspections routinely and safely. Additionally, unique use cases which can be realized using the integrated advanced 6-axis manipulator, along with its ability to operate safely during FPSO wave motion movements, will be discussed and shown to conference attendees. New for this year, a demonstration with Yokogawa's OpreX Robot Management Core (RMC) fleet management software(Note1) will occur to show that EX ROVR "ASCENT" can be full operated through a 3rd party software platform. This is a significant developmental step for EX ROVR "ASCENT" because as robotic platforms undergo wider deployments, it is essential that these technologies be integrated under centralized software platforms and work alongside multiple robotic platforms, all while maximizing use case value to end-users.

This exhibition will ensure attendees witness firsthand the use cases and the realization of instantaneous benefits through the introduction of EX ROVR "ASCENT" at Oil & Gas assets. At Mitsubishi Heavy Industries, Ltd. (MHI), we remain committed to ensuring our technologies bring the greatest value to end-users and support our customers' needs.

(Note1) Software for integrated management of inspection content and acquisition data of multiple types of robots and drones deployed in a plant

https://conference.sprintrobotics.org/

- EX ROVR “ASCENT” Collaboration with DroneDeploy

Mitsubishi Heavy Industries, Ltd. (MHI) continues an aggressive collaboration initiative to ensure EX ROVR "ASCENT" can be easily integrated with industrial inspection platform providers which operate in the Oil & Gas industry. We are excited to announce that we have established a collaborative effort with DroneDeploy to integrate EX ROVR "ASCENT" with their powerful autonomy platform for industrial inspection. This collaboration is well underway with the expectation that EX ROVR "ASCENT" can be easily integrated and maximizes the value our technology can bring to end-users coupled with DroneDeploy's platform. Our commitment for ensuring our technologies exceed customer expectations and ensure asset owners achieve operational excellence is unwavering.. Stay tuned for further exciting developments as we pursue global deployment of EX ROVR "ASCENT"!

https://www.dronedeploy.com/

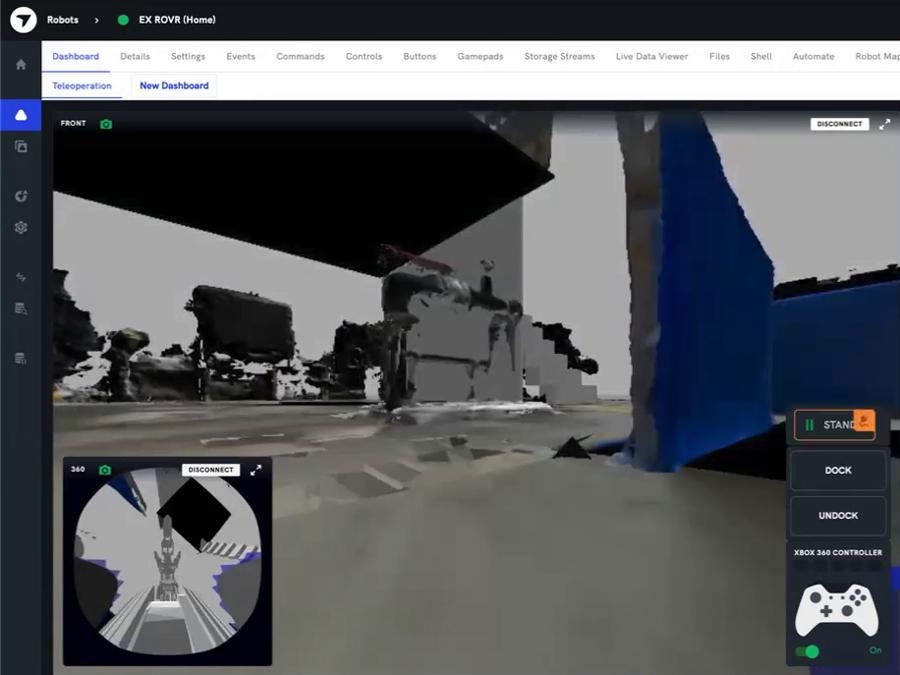

Screenshot of a simulated EX ROVR "ASCENT" being controlled from DroneDeploy's web interface.

- Autonomous Sea Trial Verifications for Future Offshore Deployments

Preparing for deployment of a new technology can be met with many challenges; however, at Mitsubishi Heavy Industries, Ltd. (MHI), we take project planning, execution, and risk management seriously. With an offshore deployment planned ahead, EX ROVR "ASCENT" has recently conducted a series of pre-deployment sea trials. These sea trials were performed with the sole purpose of validating the capability and stability of EX ROVR "ASCENT" to perform autonomous work activities while on a ship at sea. This effort is relevant to offshore assets, such as a Floating Production Storage and Offloading (FPSO), given the constant motion and directional changes caused by sea currents. As part of our risk mitigation philosophy, MHI understood it was important to instill confidence in our customer that EX ROVR "ASCENT" would be capable of performing tasks while on a FPSO.

In August 2024, the capabilities of EX ROVR "ASCENT" were tested(Note1) while on board the Luminous Kobe 2 ship(Note2) which operated from the Port of Kobe (Japan) through the Akashi Strait. Despite the ship's constant movements, the performance and reliability of EX ROVR "ASCENT" were unaffected. During this verification, the ship constantly rolled ±4-degrees (port/starboard direction) every 20-seconds which is representative of typical FPSO movements.

MHI's commitment to our customers is unwavering as we strive to ensure our technologies exceed their expectations and our project execution is well-planned. With the continued push to integrate robotic technologies at various Oil & Gas assets, we understand that it is imperative that our products operate predicably and reliably. Our efforts to instill confidence and derisk our upcoming offshore deployment represents our customer centric approach and will ultimately facilitate our customer's journey for achievement of operational excellence at their assets.

(Note1) Operational activities originated at the charging station, followed by completion of a predefined course, then returned to the charging station.

(Note2) The Luminous Kobe 2 was built at MHI's Kobe Shipyard & Machinery Works, the home of EX ROVR "ASCENT", demonstrating MHI' s comprehensive capabilities.

Autonomous Operation and Movements During Sea

±4-degrees of roll (port/starboard direction) every 20-seconds

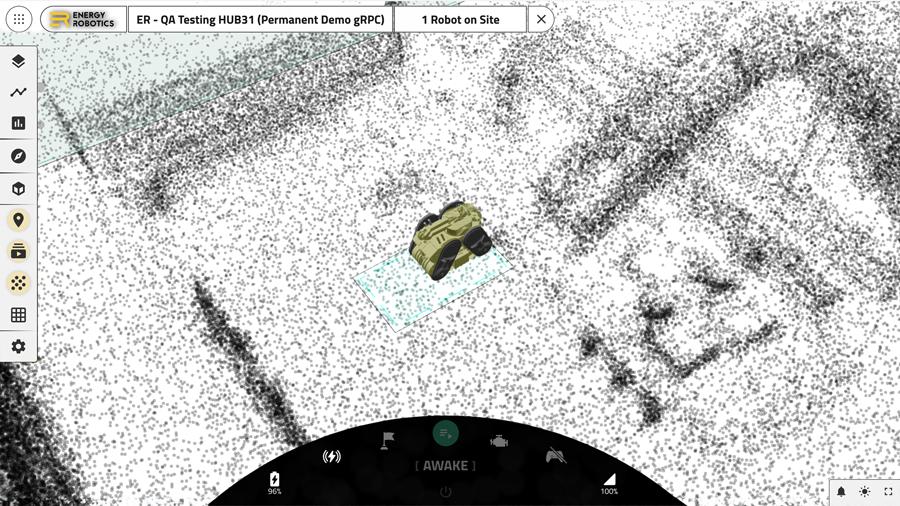

- EX ROVR "ASCENT" Collaboration with Energy Robotics

At Mitsubishi Heavy Industries, Ltd. (MHI) we understand and appreciate the serious need to simultaneously deploy multiple types of robotic technologies at plant assets, which if done effectively, will work in unison to relieve plant operator burdens, improve plant safety, and ensure asset owners achieve operational excellence. We are excited to announce that we have an ongoing collaboration with Energy Robotics GmbH to integrate EX ROVR "ASCENT" with Energy Robotics' fleet management platform. This collaboration is well underway with the expectation that EX ROVR "ASCENT" can be easily integrated and maximizes the value our technology can bring to end-users of Energy Robotics' fleet management platform. We are on an exciting journey and our commitment for ensuring our technologies bring the greatest value and support our customers' needs has never been higher. Stay tuned for further exciting updates!

Autonomous Robots for Industrial Inspections - Energy Robotics (energy-robotics.com)

Screenshot of a virtual EX ROVR "ASCENT" operating on Energy Robotics' fleet management platform.

- Awarded "Excellence Award (Social Infrastructure, Disaster Response and Fire Defense)" at the 11th Robot Awards, Japan

EX ROVR "ASCENT" received the "Excellence Award (in the fields of social infrastructure, disaster response, and fire protection)" (Note1) at the 11th Robot Awards, organized by the Japanese Ministry of Economy, Trade and Industry. The award was given in recognition of its contribution to future market creation and high expectations. An award ceremony was held at the Tokyo Big Sight on September 18, and EX ROVR "ASCENT" was exhibited at the "Japan Robot Week 2024" joint exhibition of the award winners from September 18 to 20th, where the company engaged in an active technological exchange with other robotic companies.

Taking advantage of this award, the company will continue to improve the hardware and software of EX ROVR "ASCENT". In addition, the company will continue to propose solutions using explosion-proof robot technology for "safety and security" in diverse environments. MHI will continue to make technological contributions toward the development of robotics technology and the expansion of robot utilization in Japan.

(Note1) Applications submitted by five organizations: Mitsubishi Heavy Industries, Ltd. (main developer), ENEOS Co., Ltd., Tohoku University, Yamagata University, and Chiba Institute of Technology.

- EX ROVR "ASCENT" Testing is Underway at TotalEnergies' TADI site.

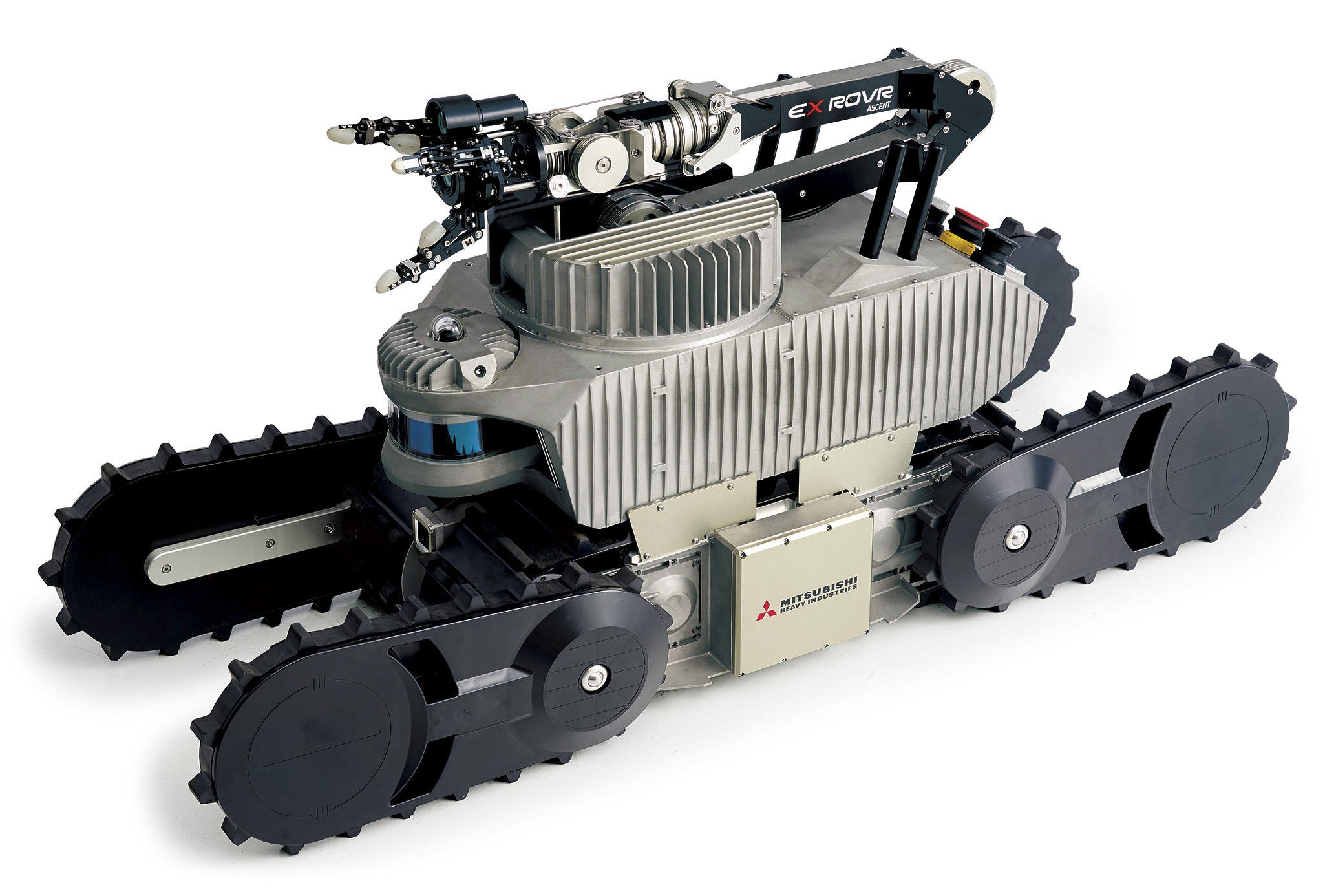

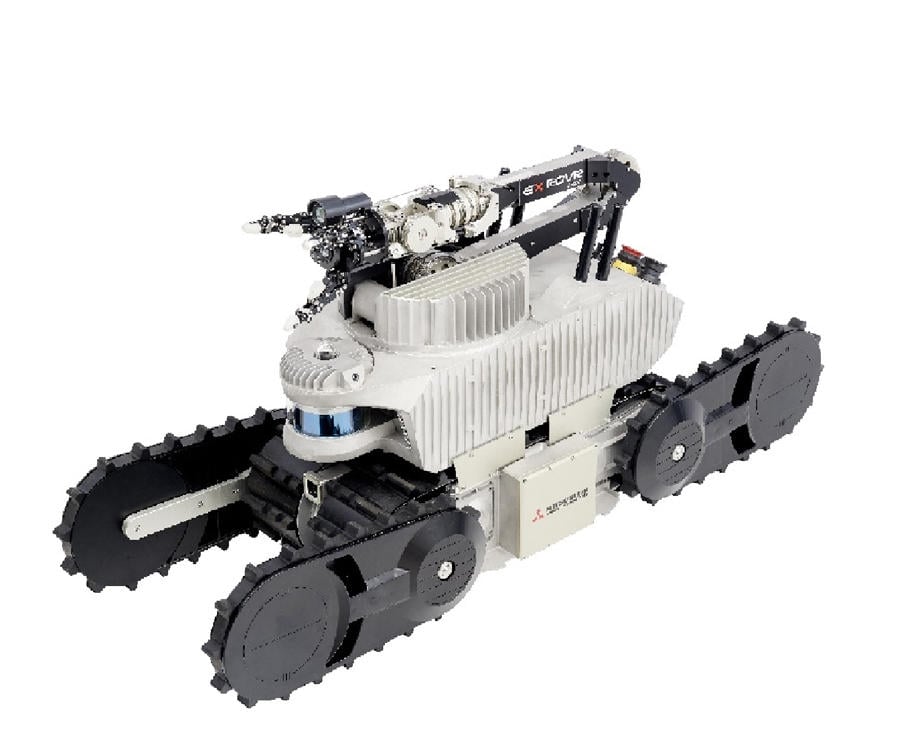

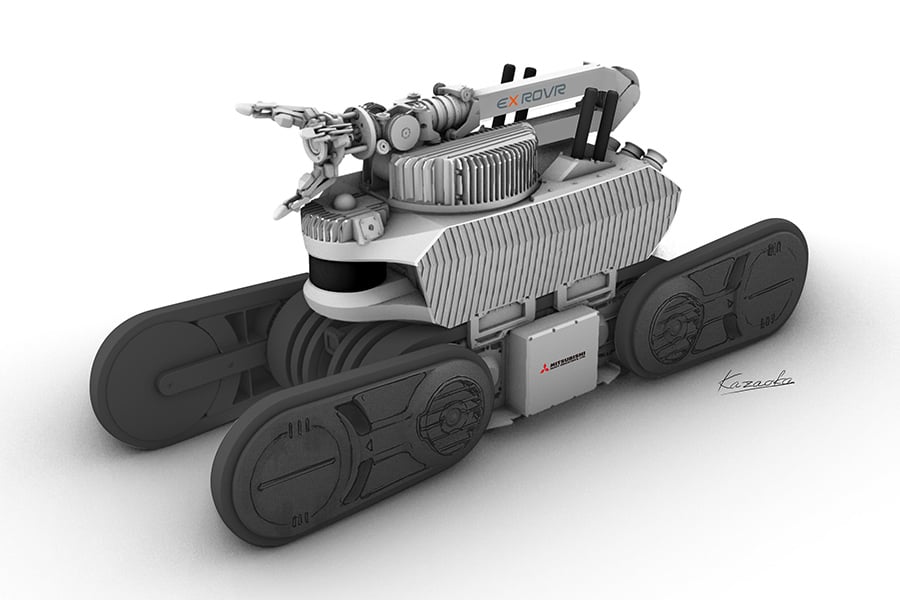

TotalEnergies has initiated a test of EX ROVR "ASCENT" at their TADI (TotalEnergies Anomaly Detection Initiatives) site over the course of several months, to confirm the functionality and applicability of the robot to perform plant restart functions, such as, maneuvering buttons and switches, as well as its capability for autonomous round inspections. TADI is TotalEnergies' designated site for testing and qualifying innovative gas leak detection and greenhouse-gas emission quantification technologies. Since this site was constructed using equipment from a former gas production plant, it provides an ideal environment for testing robotic technologies. With support of our engineers, TotalEnergies' site engineers created 3D maps and scenarios such that EX ROVR "ASCENT" would conduct autonomous missions, including traversing multiple levels by ascending and descending stairs. EX ROVR "ASCENT", the robot and its charging station, is ATEX and IECEX Zone 1 certified and is uniquely designed to be stable, maneuverable, capable of climbing stairs due to its crawlers, and includes a suite of sensors and cameras for collecting data. Most notably, using the integrated 6-axis state-of-the-art manipulator provides users end-less possibilities to perform work safely and collect data in hard to reach areas. Given it's unique features, EX ROVR "ASCENT" can play the role as a first responder for unexpected situations which may arise at a site. Since its launch in 2022, EX ROVR "ASCENT" has been delivered to several customers and is currently being tested in various locations around the world. With its functions, EX ROVR "ASCENT" will help customers reduce employee workload at their facilities, improve safety, and improve plant operation.

- EX ROVR "ASCENT" present at YNOW2024

MHI is excited to have EX ROVR "ASCENT" at the YNOW2024, YOKOGAWA Users Conference, in Houston, Texas from October 28-30, 2024. During this time, EX ROVR "ASCENT" will be utilized by YOKOGAWA to demonstrate integration and operation with their fleet management software OpreX Robot Management Core (RMC). As robotic platforms undergo wider deployments, it is essential that these technologies be integrated under centralized software platforms and work alongside multiple robotic platforms, all while maximizing use case value to end-users. MHI is happy to support YOKOGAWA and will have representatives present to discuss EX ROVR "ASCENT".

YNOW2024: A Yokogawa Users Conference | Yokogawa America

- EX ROVR "ASCENT" operability confirmed with YOKOGAWA OpreX Robot Management Core (RMC)

How plant operations are conducted continues to evolve and with the ultimate desire to achieve unmanned operations, innovative technologies are essential. EX ROVR "ASCENT" provides plant operators a unique solution for performing routine inspections automatically and responding to emergent situations. At Mitsubishi Heavy Industries, Ltd. (MHI) we understand and appreciate the serious need to simultaneously deploy multiple types of robotic technologies in a plant, which if done effectively, will work in unison to relieve plant operator burdens and improve plant safety. This can only be accomplished if all robotic technologies are integrated in an agnostic manner, along with their operation and acquired data be managed by a common fleet management software platform. As part of our continued development, EX ROVR "ASCENT" has been confirmed to be fully capable of being managed, supported, and its data collection performed by OpreX Robot Management Core (RMC), produced by YOKOGAWA, which is a software platform for integrated management of robots. This accomplishment is yet another example of MHI's commitment to ensure our technologies bring the greatest value to end-users and support our customers' needs.

https://www.yokogawa.com/solutions/solutions/asset-management-and-integrity/robot-management-core/

- ENEOS Oita and Negishi Refinery Proof of Concept (PoC) Videos

Through a joint R&D program with ENEOS Corporation, EX ROVR "ASCENT" is embarking on PoCs at their Negishi Refinery, after successfully completing PoCs at their Oita Refinery.

These PoCs are conducted autonomously to collect valuable inspection data and includes traversing throughout a multistoried operating plant.

EX ROVR "ASCENT" continues to confirm its operational performance and prove its value for achievement of ENEOS's patrol inspection expectations.

- MHI successfully showcased EX ROVR "ASCENT" at the 2024 Offshore Technology Conference held in Houston, Texas in May. During this time, multiple autonomous inspection operations demonstrations were performed for numerous conference attendees. Since EX ROVR "ASCENT" has unique features and excellent maneuverability, MHI demonstrated the value which EX ROVR "ASCENT" can bring end-users for their unique use cases.

https://2024.otcnet.org/

- MHI will run a booth at SPRINT Robotics World Conference for Inspection & Maintenance Robotics

https://conference.sprintrobotics.org/

Second-generation EX ROVR: "ASCENT"

- The hardware design of EX ROVR Gen 2.0 (to be released in 2022) has been finalized : this is what it looks like

Real EX ROVR

Plan image

- EX ROVR Summer Live Demonstration 2020

We presented our latest prototype robot (Gen 1.5) to domestic and international customers in the oil, gas, and chemicals industries. We built a mockup plant in one of our factories in Kobe and performed an online, live demonstration of an autonomous inspection. Footage of the demonstration can be found in the "Movies" tab.

There is also a narrated Powerpoint available under the "Support" tab.

Business Contact

Please send to the inquiry form below or your email address.

Distributors :