Press Information

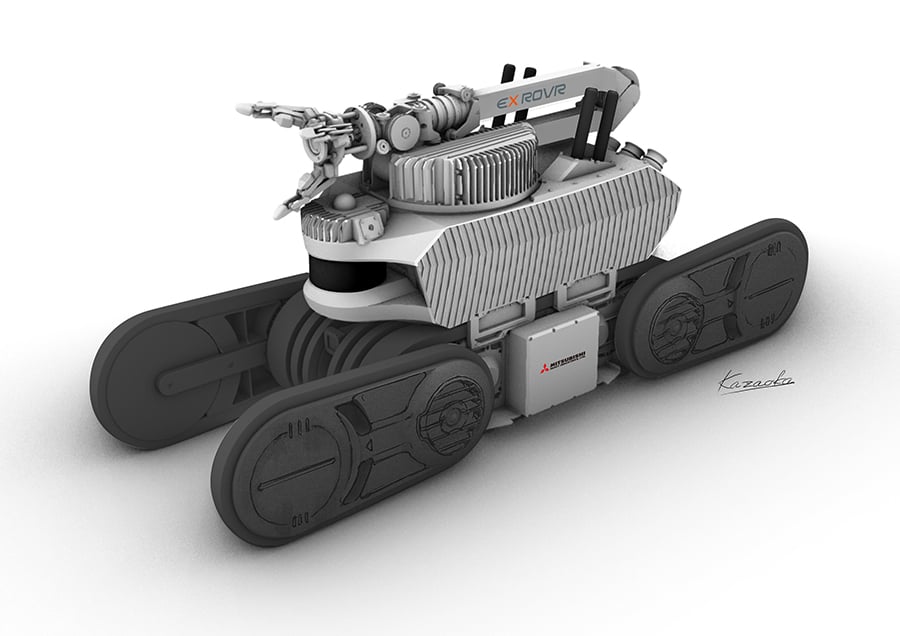

MHI Concludes Agreement with ENEOS on Joint Development of Explosion-proof Robot for Inspection in Oil Refineries -- Target on Practical Viability of Second-generation EX ROVR --

・ Follows field demonstration of prototype under joint research agreement concluded in April 2018

・ Practical application to come by enhancing usability through software improvements and incorporation of manipulator

Tokyo, September 10, 2020 – Mitsubishi Heavy Industries, Ltd. (MHI) has concluded an agreement with ENEOS Corporation on joint development of a second-generation EX ROVR, a plant inspection robot with explosion proof features to limit the danger of the robot igniting an explosion or fire from electric sparks or heat, even in areas with flammable gas. The agreement, which targets early realization of a practically viable model, follows an earlier agreement, signed in April 2018, on joint research into the practical feasibility of an explosion-proof plant inspection robot.

Under the joint research agreement with ENEOS, valid through FY2019, a prototype EX ROVR moved autonomously through several floors of an oil refinery and collected data through its various sensors, thereby demonstrating its feasibility in the field and confirming that it meets all basic function requirements as a plant inspection robot. Under the newly agreed joint development program, on-site data of greater volume and higher quality will be pursued through software improvements and the incorporation of a manipulator for photographing instrumentation from a directly facing position. Targets will also include enhancing customer usability and achieving a more practical robot equipped with explosion proof features.

The plant inspection robot with explosion proof features under development is based on MHI’s robot technologies that have yielded excellent results in supporting containment activities in the aftermath of the nuclear power plant accident. The EX ROVR’s explosion-proof design complies with Japan’s domestic guidelines as well as the ATEX and IECEx (Note) explosion proof standards widely adopted in Europe and around the world, allowing it to be used safely in areas with an explosive gas atmosphere (Zone 1).

Going forward, MHI will proactively propose new solutions applying its explosion-proof robot technologies as a way of contributing to enhanced plant safety and productivity.

- IECEx is an international system for certifying equipment for use in explosive atmospheres. Its quality assessment provisions are based on standards created by the International Electrotechnical Commission (IEC). The ATEX Directive, which is based on IECEx, stipulates the health and safety requirements, and conformity assessment procedures, that must be met in order to bring to the EU market equipment or protective systems for use in explosive atmospheres. As IECEx and ATEX follow the same standards, there is fundamentally no difference in terms of their technical details.

About MHI Group

Mitsubishi Heavy Industries (MHI) Group is one of the world’s leading industrial groups, spanning energy, smart infrastructure, industrial machinery, aerospace and defense. MHI Group combines cutting-edge technology with deep experience to deliver innovative, integrated solutions that help to realize a carbon neutral world, improve the quality of life and ensure a safer world. For more information, please visit www.mhi.com or follow our insights and stories on spectra.mhi.com.