EX ROVR "ASCENT", the autonomous, explosion-proof, plant inspection robot : Introduction

Introduction

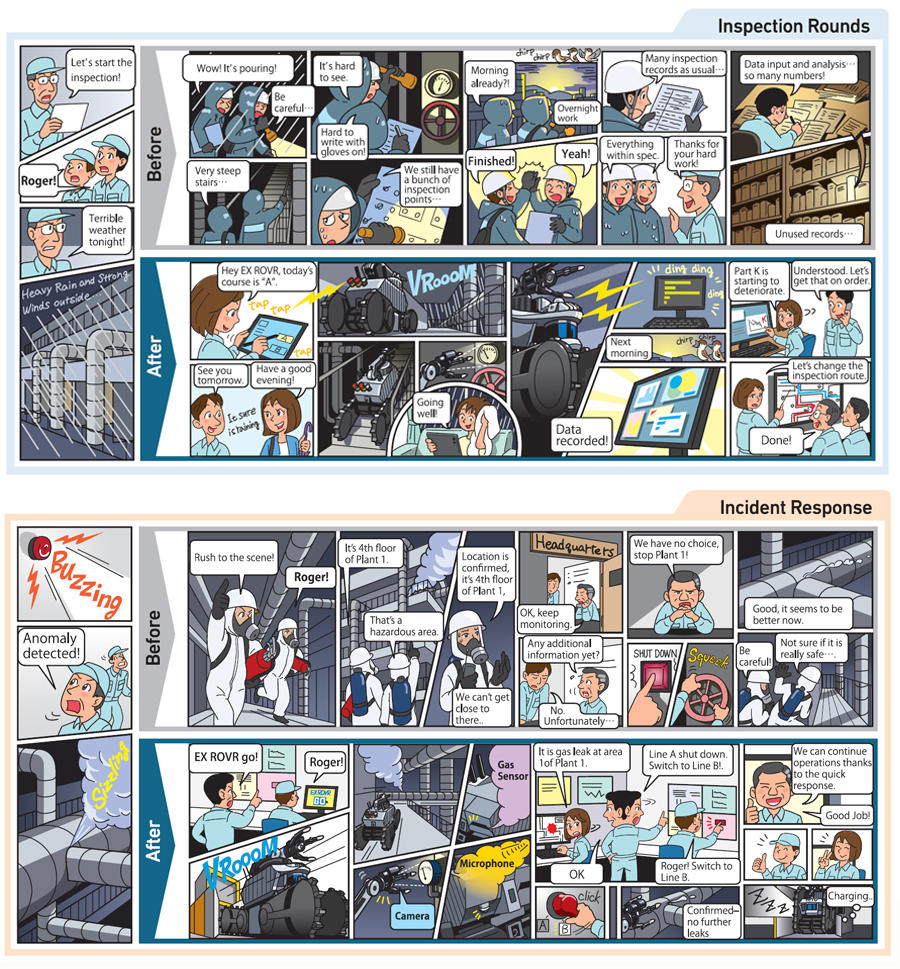

Robot works alongside human operators to enhance efficiency and safety in the work environment.

- ■ High-frequency, multi-sensor inspections and efficient use of data

- ■ Safe and timely resolution of any detected anomalous conditions

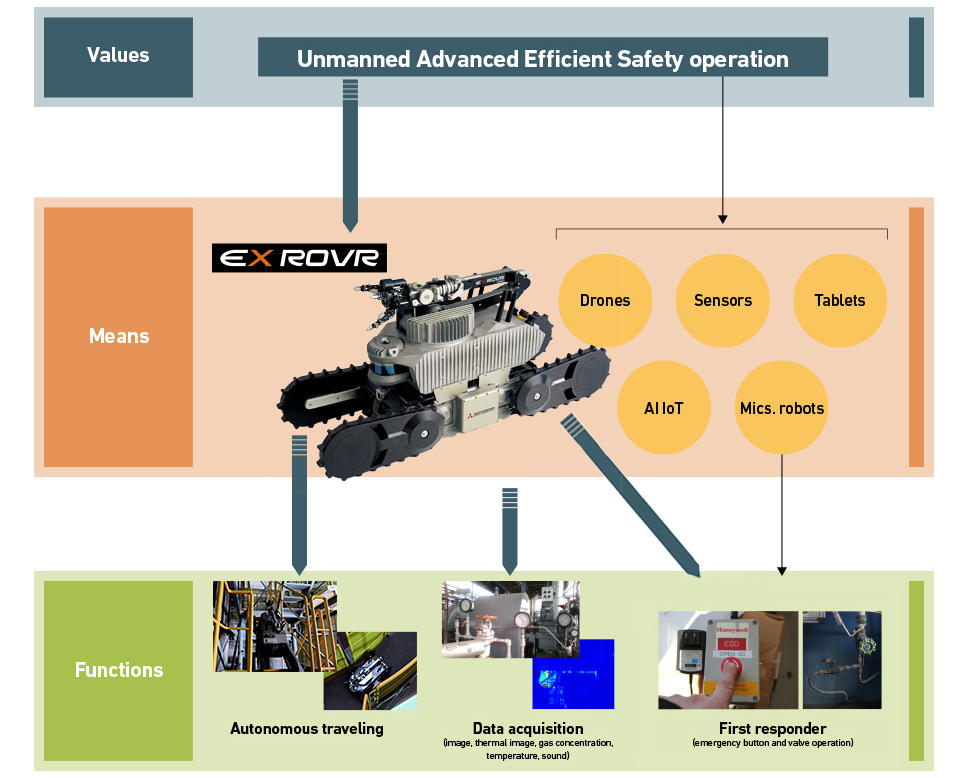

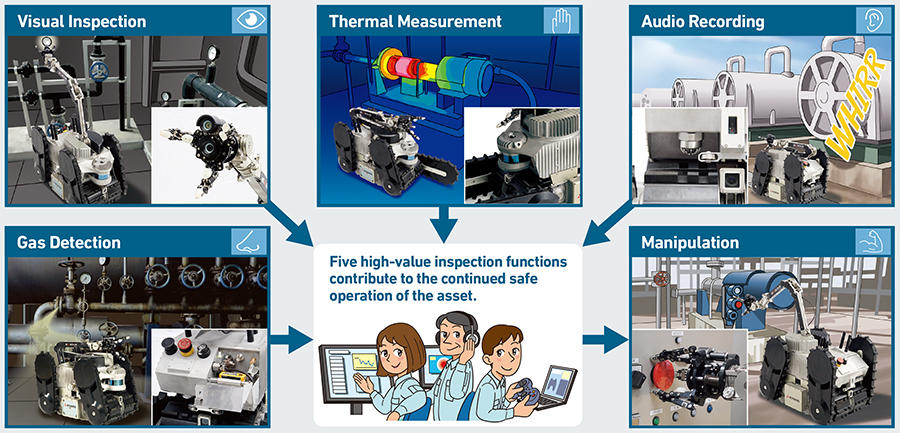

The value drivers of deploying an autonomous, explosion-proof, plant inspection robot which can acquire asset data through visual imaging, thermal scans, acoustic mapping, and gas concentrations with its suite of advanced sensors

- ■ Safer Operation

- Removing human operators from potentially dangerous situations

- ■ Cost Efficiency

- Avoidance of non-value add & highly repetitive tasks which frees human operator for more productive jobs

- ■ Highly Repeatable & More Frequent Inspections

- Preventing unplanned shutdown by more frequent inspection

- ■ Enhanced Predictive Maintenance

- Digital inspection data analytics; data is fully searchable & trendable (IoT, AI)

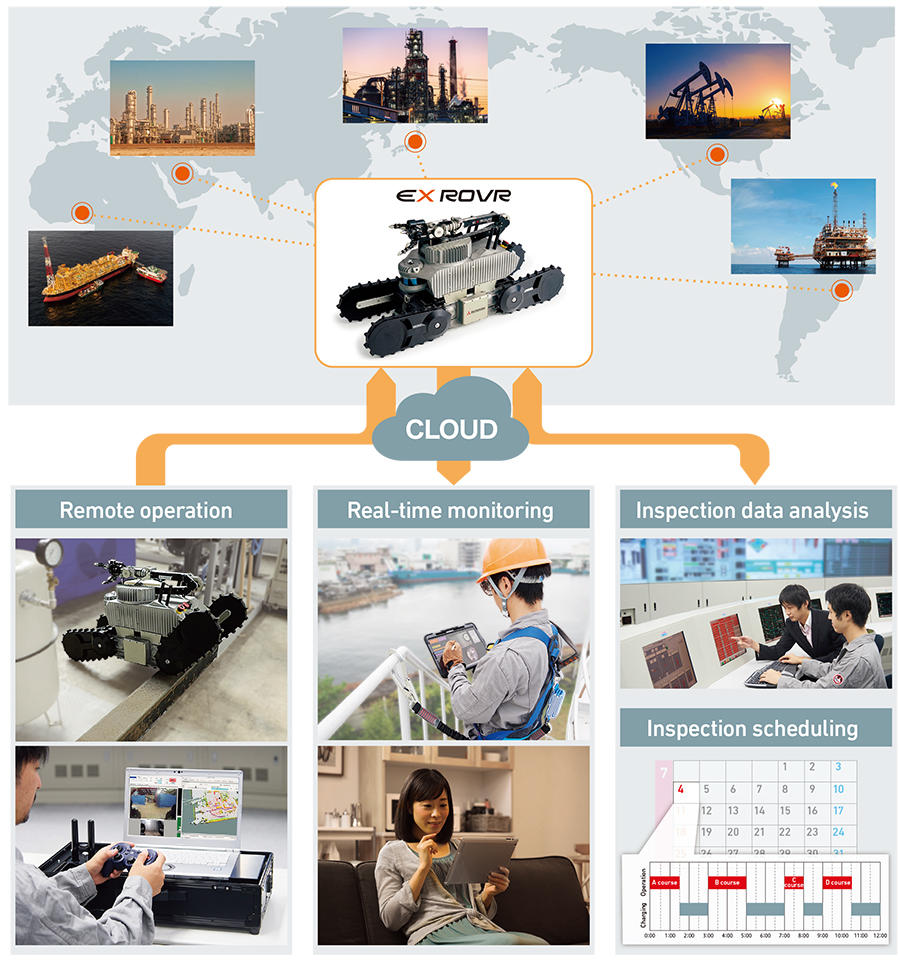

Mobile super-sensor integrated to IoT

EX ROVR will maximize customer value by safely acquiring and integrating key information at the asset

EX ROVR will be a key component in achieving unmanned, advanced, efficient, and safer plant operations

Reliable partner for autonomous plant inspection

EX ROVR can perform inspection rounds day & night in potentially hazardous locations (Zone 1) increasing the safety and efficiency of the asset.

Digitalization of inspection records streamlines the data analysis process freeing up operators for higher value tasks.

EX ROVR protects your employees, assets, and effectively contributes to a human friendly working environment.

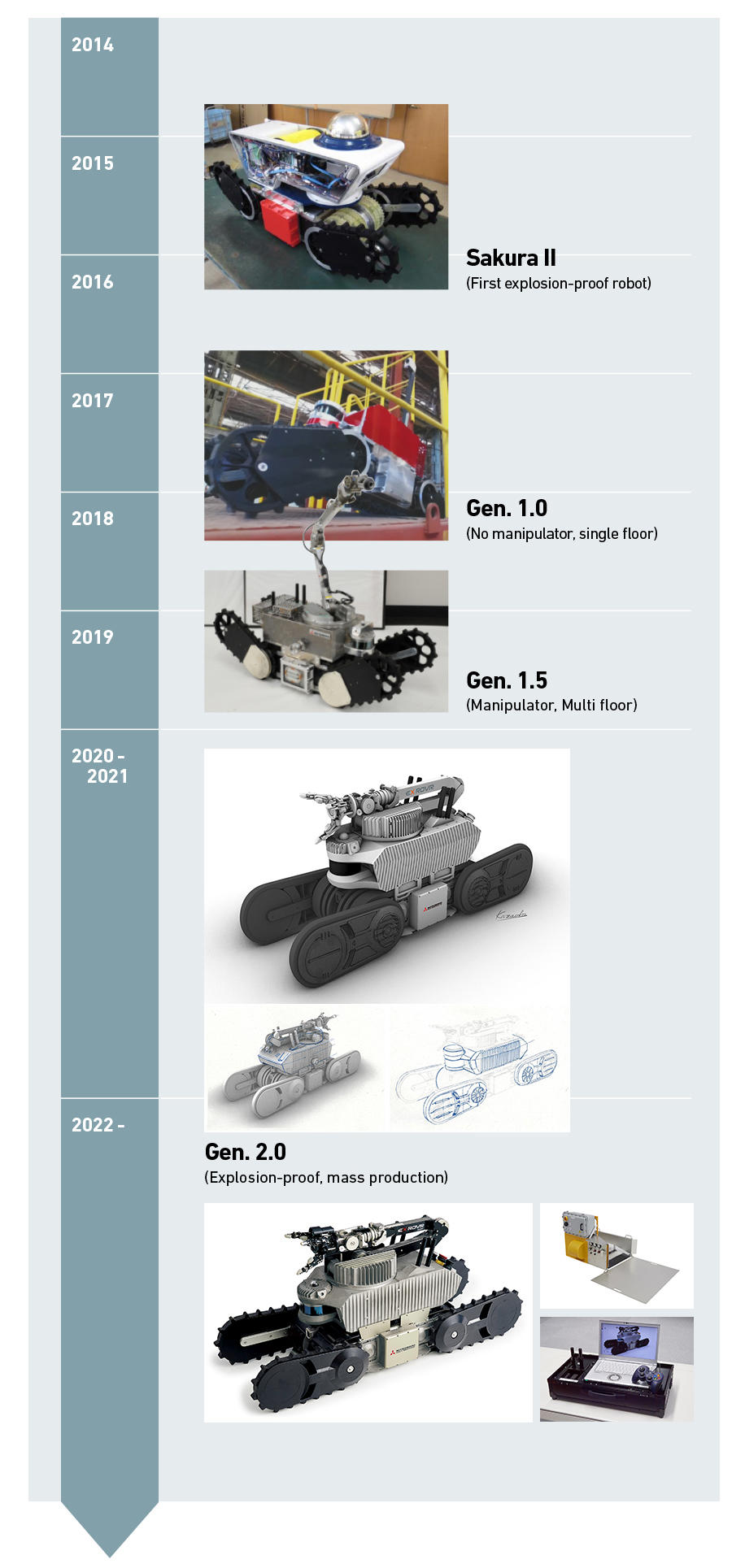

Development Journey

Business Contact

Please send to the inquiry form below or your email address.

Distributors :