Overview of Intelligent Logistics Solutions

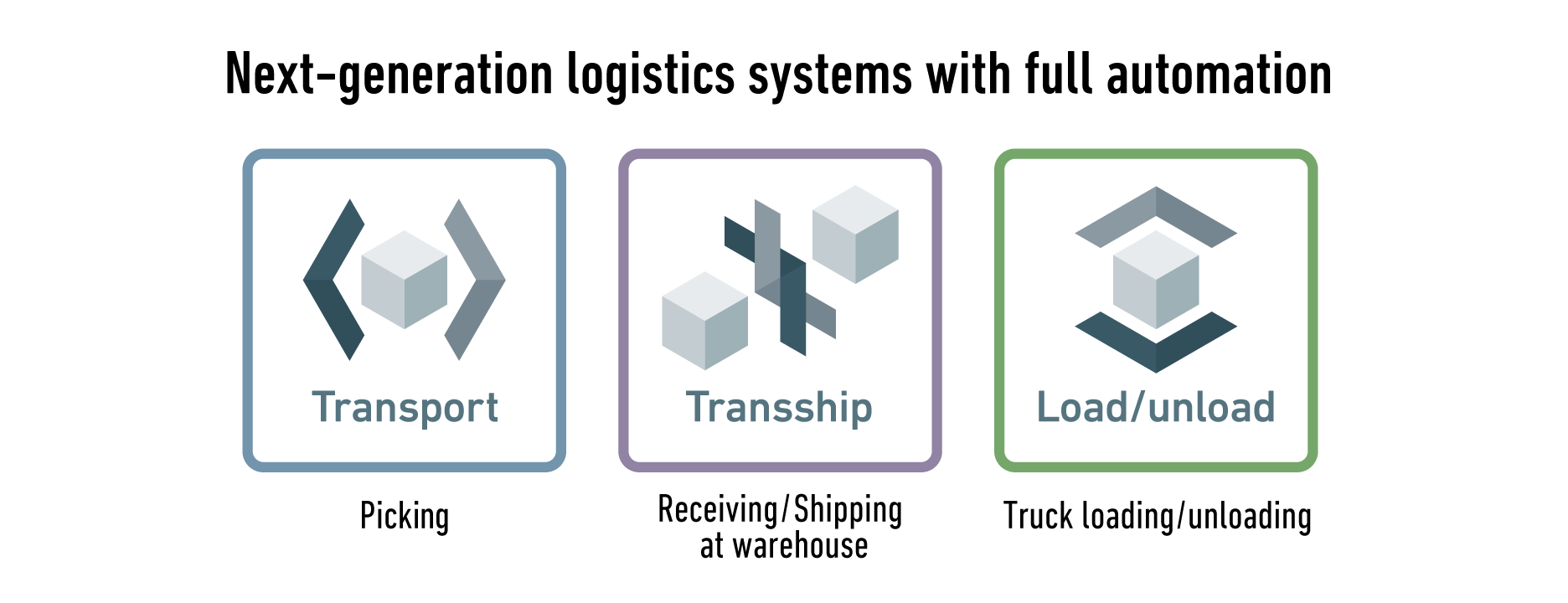

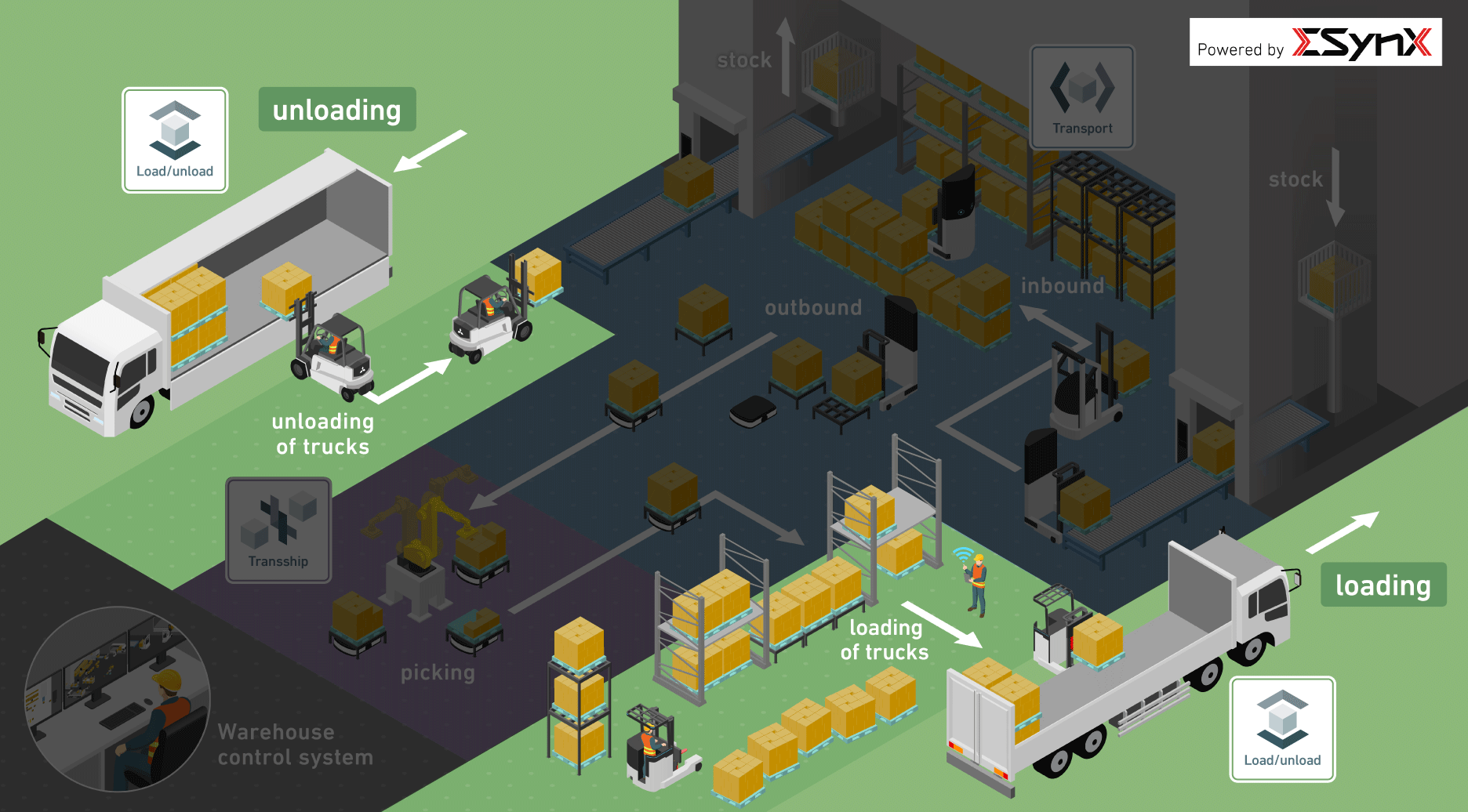

Our solution integrates control of various automated logistics and material handling equipment, both ours and other companies’, in the process from receiving to shipping at logistics sites by ΣSynX® (Sigma Syncs). In particular, in the areas of "automatic picking," "automatic receiving/shipping," and "truck loading/unloading," intelligent and automated systems can be realized in a manner that is optimized for the customer's site conditions and challenges.

Advantages of Intelligent Logistics Solutions

1. Achieve manpower savings from multiple perspectives

In addition to utilizing logistics and material handling equipment that operates 24 hours a day, precise instructions to workers reduce training costs and improve overall operational efficiency. Visualization of inventory and location information not only improves the efficiency of logistics operations but also enables reallocation of resources to other departments such as production and management.

2. Enable synchronization and coordination of equipment regardless of the manufacturer

Our solutions enable synchronization and coordination of equipment from different manufacturers, which was difficult with conventional automation solutions. With ΣSynX, we enable not only partial optimization of each equipment but also total optimization of the warehouse.

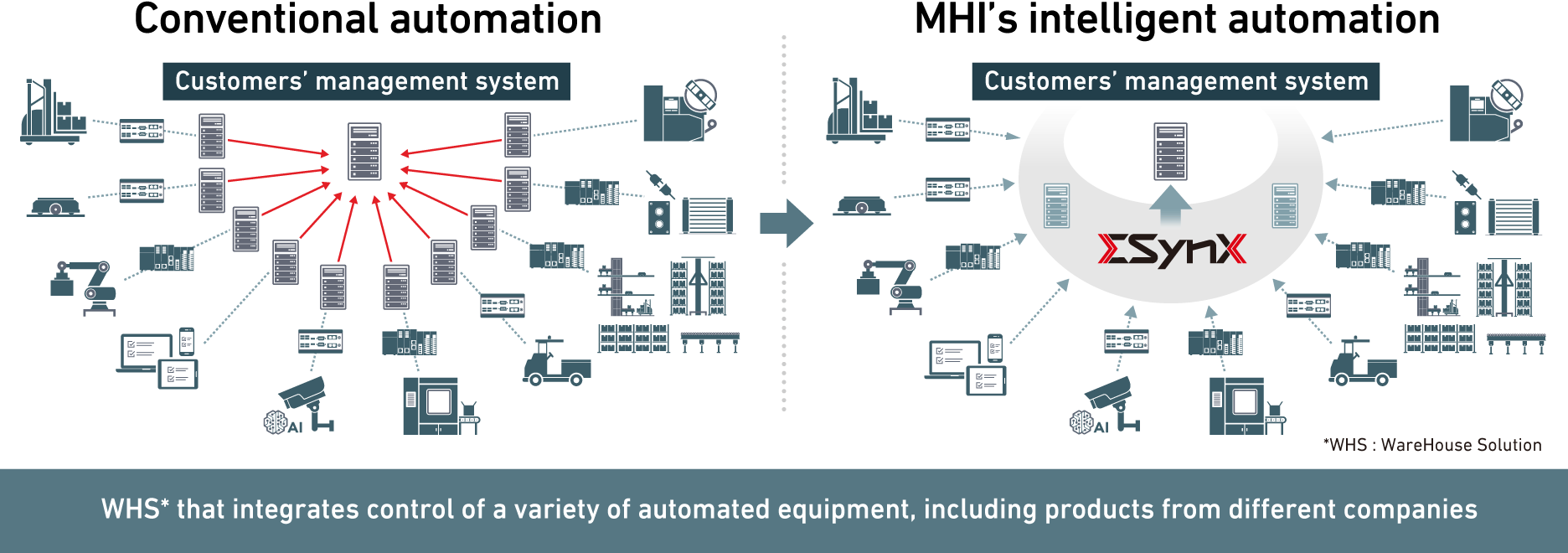

3. We can propose the optimized implementation for each customer

We analyze the customers' warehouse conditions and issues there in detail, and conduct front-end engineering with a view to new development as needed. We verify the expected effects of implementation in advance through simulations based on operational records and survey results, and propose the most appropriate plan with a high return on investment, including partial implementation even in one corner of the warehouse only.

< Output image of simulation results >

4. Full knowledge of both software and hardware

In addition to the development of integrated control systems equipped with ΣSynX, our expertise in various hardware as a manufacturer enables system customization that brings out the better performance of hardware. In particular, maximized installation effects can be expected by linking with unmanned forklifts made by Mitsubishi Logisnext.

Details of Intelligent Logistics Solutions

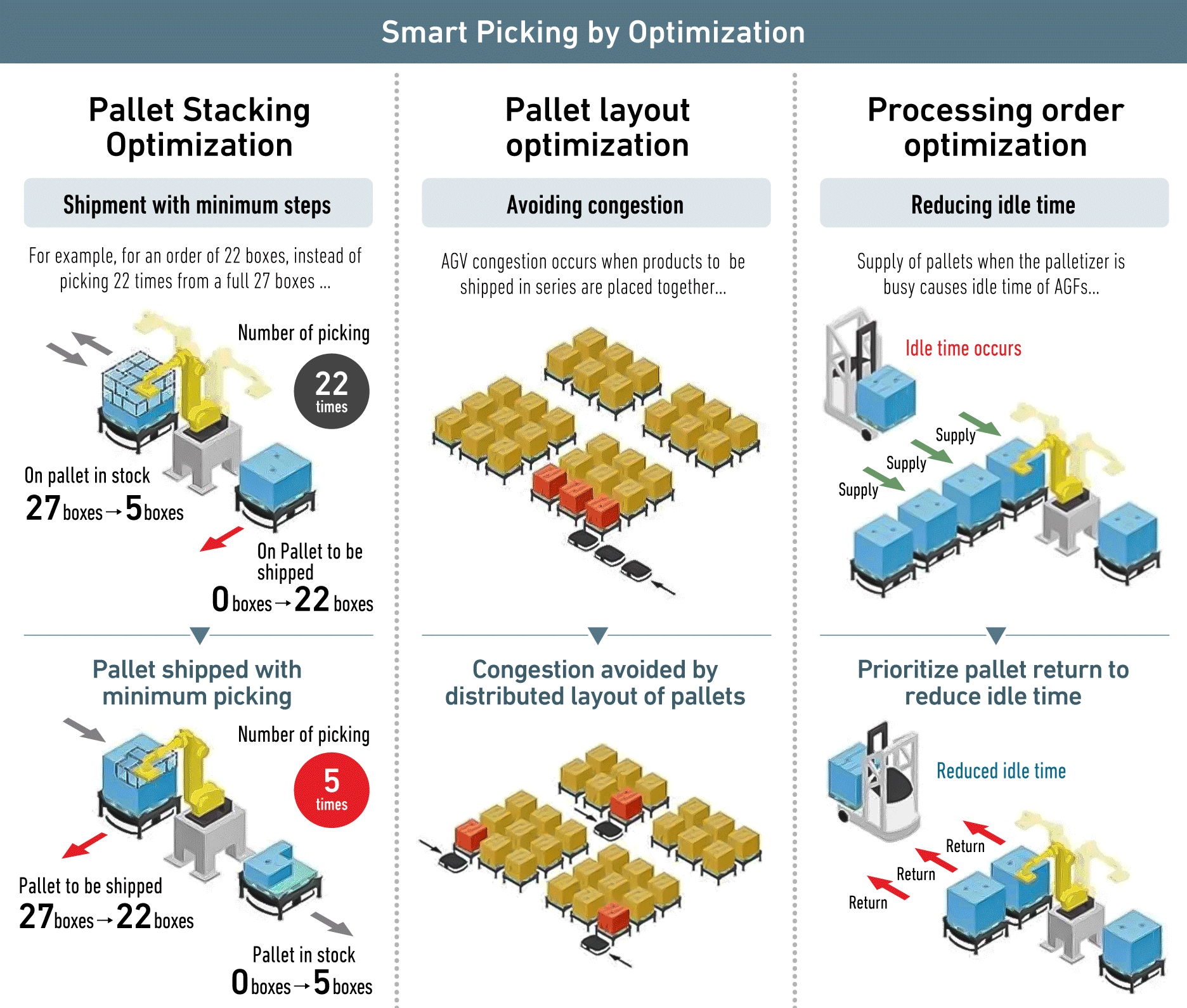

Our unique optimization engine and integrated control system combine AGF (Automated Guided Forklift), AGV (Automated Guided Vehicle), and palletizer to constitute an automated picking system. The system incorporates the know-how of skilled workers to intelligently automate complex picking operations that previously relied on human hands or personal experiences. This contributes to manpower saving, reduction of human errors, and improvement of safety, storage efficiency, and throughput.

For example, by optimizing the stacking and placement of pallets and streamlining the order processing sequence, overall processing capacity can be greatly improved.

Automated receiving/shipping

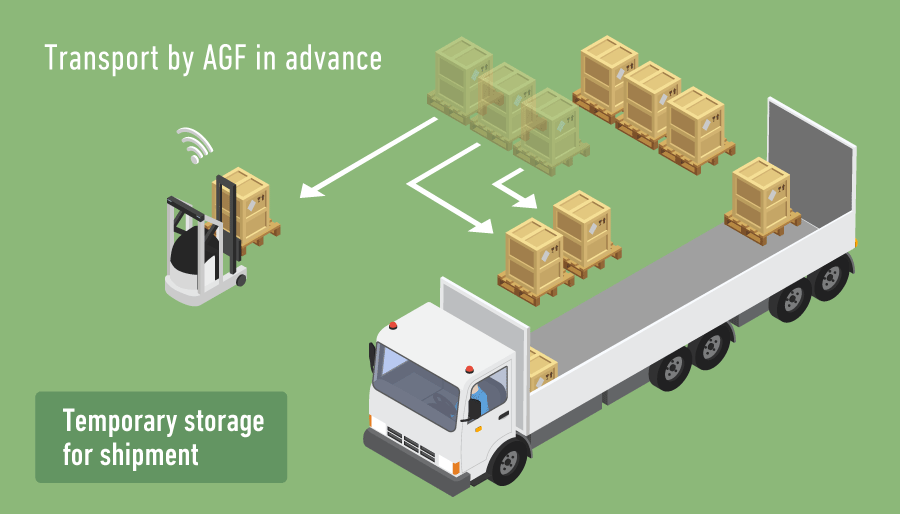

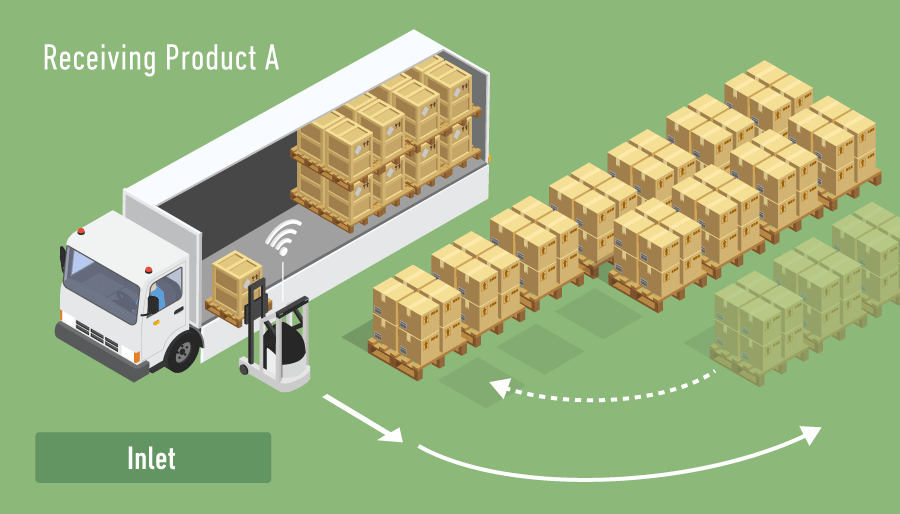

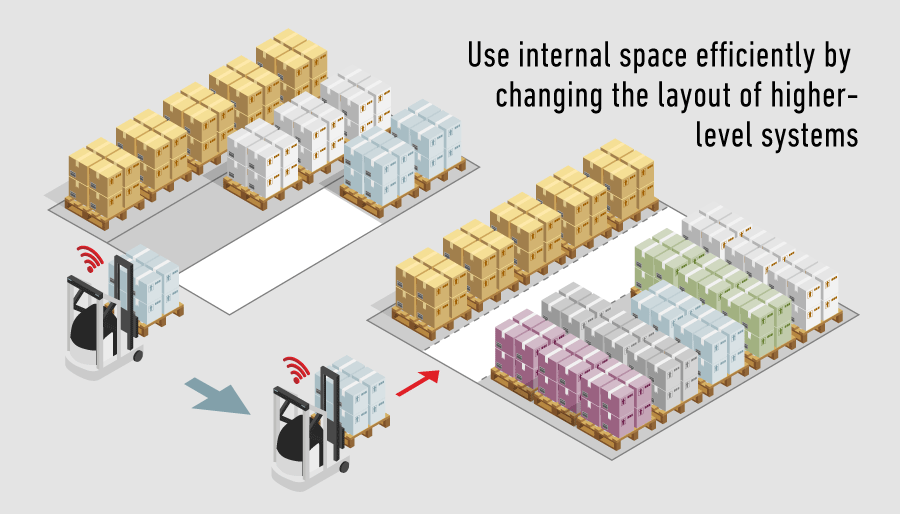

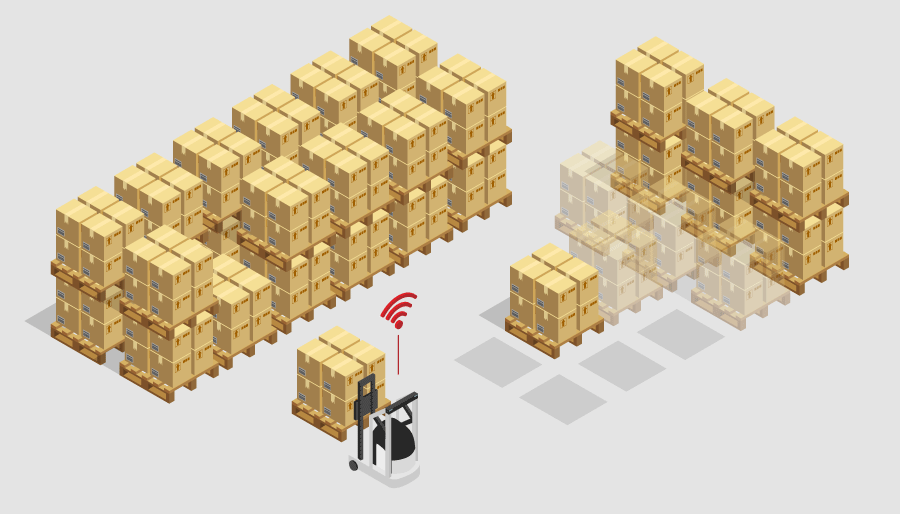

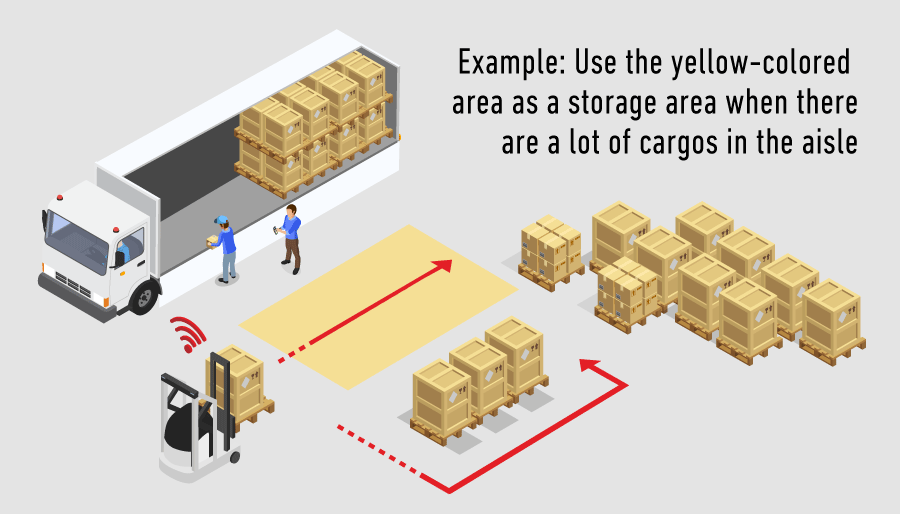

In response to daily changes in inventory locations and shipment volumes, ΣSynX optimally controls logistics and material handling equipment according to the latest demand and plans. Smart warehouse operations can be implemented by utilizing the know-how of skilled workers in determining location areas and rearranging operations. This contributes to reducing truck waiting time, improving storage efficiency, and increasing throughput.

<Example of warehouse operations using ΣSynX>

(1) Outgoing shipment / Align cargos neatly before arrival of truck

(2) Incoming delivery / Rearrange cargo before arrival of truck

(3) Automatically change storage layout according to the number of items and volume (maximize storage efficiency)

(4) Automatically eliminate gaps in rows

(5) Avoid distortions by switching the upper and lower cargos (Maintain quality)

(6) Automatically set the route for AGF so it can run the shortest distance

Automating truck loading and unloading (under development)

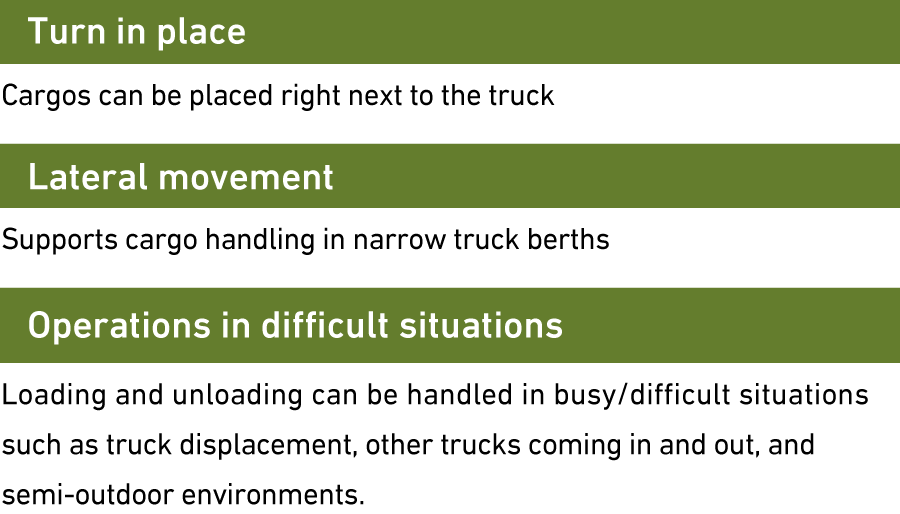

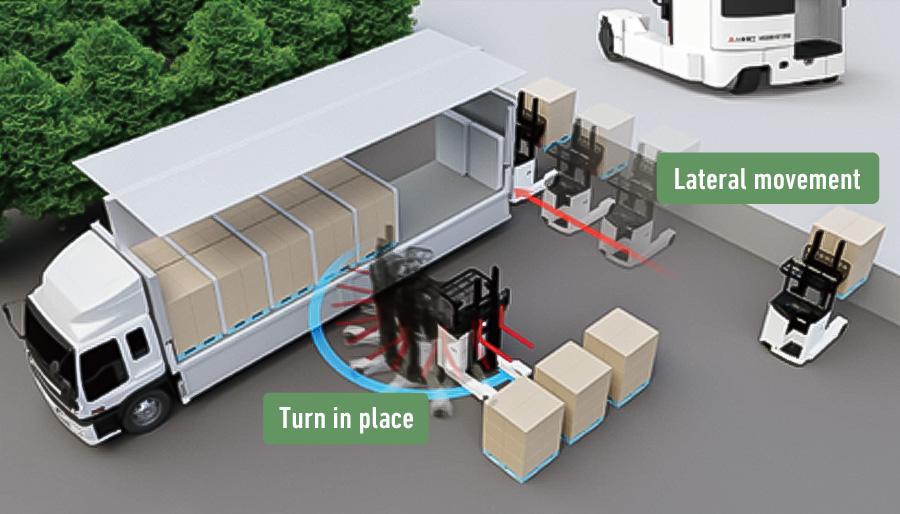

In order to respond to various environmental and operational conditions affecting truck berths (Note), we are developing an AGF (Automated Guided Forklift) all of whose wheels can be used to steer. It is equipped with functions for turning in place and lateral movement to enable loading and unloading operations to be efficiently coordinated with human workers. In addition, we are further developing a coordination system between humans and unmanned forklifts by ∑SynX for safe collaboration between humans and machines, such as installing cushioning materials in between cargos, aiming at commercialization. We are committed to providing a logistics system that can be flexibly applied to suit customers’ workplace environments while maintaining high safety and increasing autonomous opearions.

(Note) Space for trucks to be parked just outside the warehouse for loading and unloading

Setting up facilities and operation optimization for a freezer/ refrigerated warehouse logistics

In addition to intelligent logistics solutions, MHI Group is engaged in a wide range of fields, including thermal and refrigeration equipment, power generation systems, and even warehouse construction. Leveraging these comprehensive strengths, we can provide a one-stop service from basic design of a freezer/refrigerated warehouse, to selection of optimal equipment, and implementation of intelligent logistics solutions using ΣSynX. This also contributes to shortening the lead time for customers to start operating refrigerated warehouses.

Related Information

Related Products and Services

Related Articles from Spectra - Our Online Magazine

Related Press Releases

- Mitsubishi Logisnext to Demonstrate Automated Forklift Equipped with "SynfoX" at "4th INNOVATION EXPO"-- Contributing to Warehouse Automation Using MHI's "ΣSynX" Elemental Technologies --

- MHI's Automated Picking Solution Utilizing ΣSynX Fully Implemented at Kirin Group's Ebina Logistics Center, the First Such System in Japan

- MHI and Mitsubishi Logisnext to Display "ΣSynX" Products Enabling Autonomous and Intelligent Warehouse Logistics

- ΣSynX "Smart Connections" Provides Solutions for the Various Challenges Facing Society

- MHI to Provide the "ΣSynX Supervision" Remote Monitoring Service as a Digital Innovation Brand

- MHI and Mitsubishi Logisnext to Commence Provision of Automated Picking Solutions for Warehouses Based on “ΣSynX”