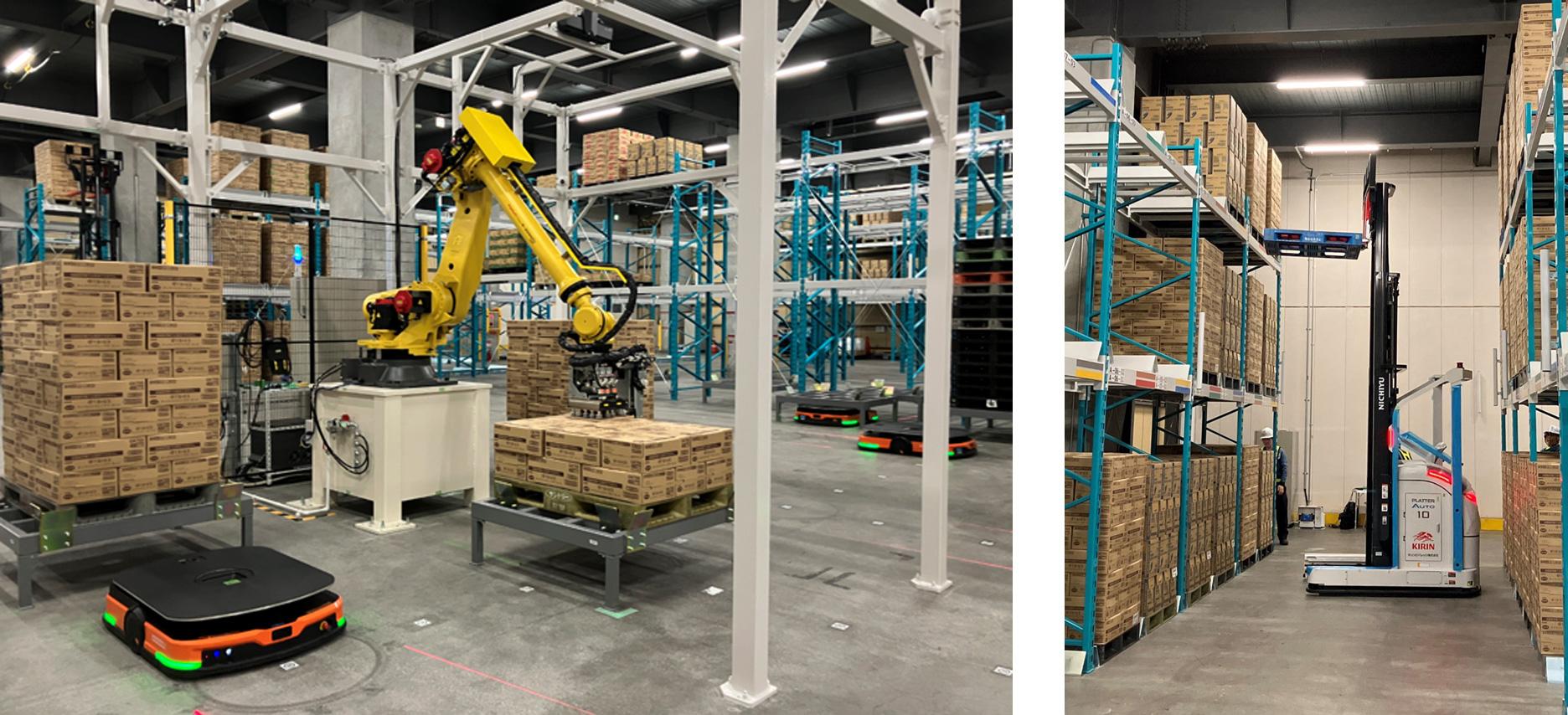

Kirin Group Introduces Automatic Picking Solution Using ΣSynX® at Ebina Distribution Center

In December 2024, an automatic picking solution using ΣSynX® (Sigma Syncs) went into operation at the Ebina Distribution Center (Ebina City, Kanagawa Prefecture) managed by East Japan Regional Office, Shonan Branch of Kirin Group Logistics.

At the center, 4 unmanned forklifts, 11 AGVs, and 1 picking robot operate under integrated control of ΣSynX, which automates picking and material handling operation that had previously been performed by human workers.

When introducing our solution, a part of the manned picking area was designated as an automated area, and about half of the cases handled at the center per day are now subject to automated picking. In the future, we plan to gradually increase the volume of shipments using this solution.

Related Information

Related Products and Services

Related Articles from Spectra - Our Online Magazine

Related Press Releases

- Mitsubishi Logisnext to Demonstrate Automated Forklift Equipped with "SynfoX" at "4th INNOVATION EXPO"-- Contributing to Warehouse Automation Using MHI's "ΣSynX" Elemental Technologies --

- MHI's Automated Picking Solution Utilizing ΣSynX Fully Implemented at Kirin Group's Ebina Logistics Center, the First Such System in Japan

- MHI and Mitsubishi Logisnext to Display "ΣSynX" Products Enabling Autonomous and Intelligent Warehouse Logistics

- ΣSynX "Smart Connections" Provides Solutions for the Various Challenges Facing Society

- MHI to Provide the "ΣSynX Supervision" Remote Monitoring Service as a Digital Innovation Brand

- MHI and Mitsubishi Logisnext to Commence Provision of Automated Picking Solutions for Warehouses Based on “ΣSynX”