We are promoting intelligent logistics that coordinate

among machines and also between machines and humans

to contribute to solving issues in logistics field

MHI’s Initiative to Address Challenges in Logistics

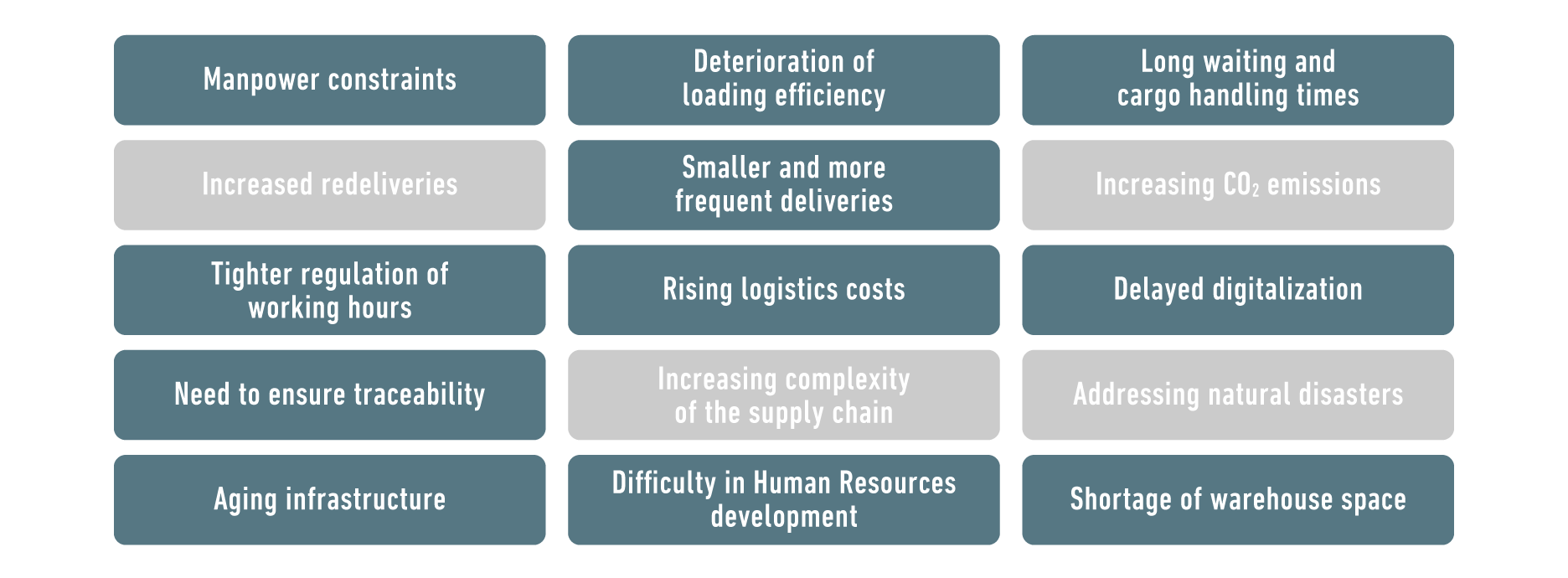

< Issues in Logistics that MHI Group’s Solutions Can Address >

The logistics industry is facing multiple challenges, including rising costs, a requirement to reduce CO2 emissions, and a growing shortage of human resources. In particular, tighter regulations on driver working hours require urgent action. For example in Japan, without effective measures to solve these problems, it is estimated that commercial trucking capacity will fall by 34.1% by 2030 (Note).

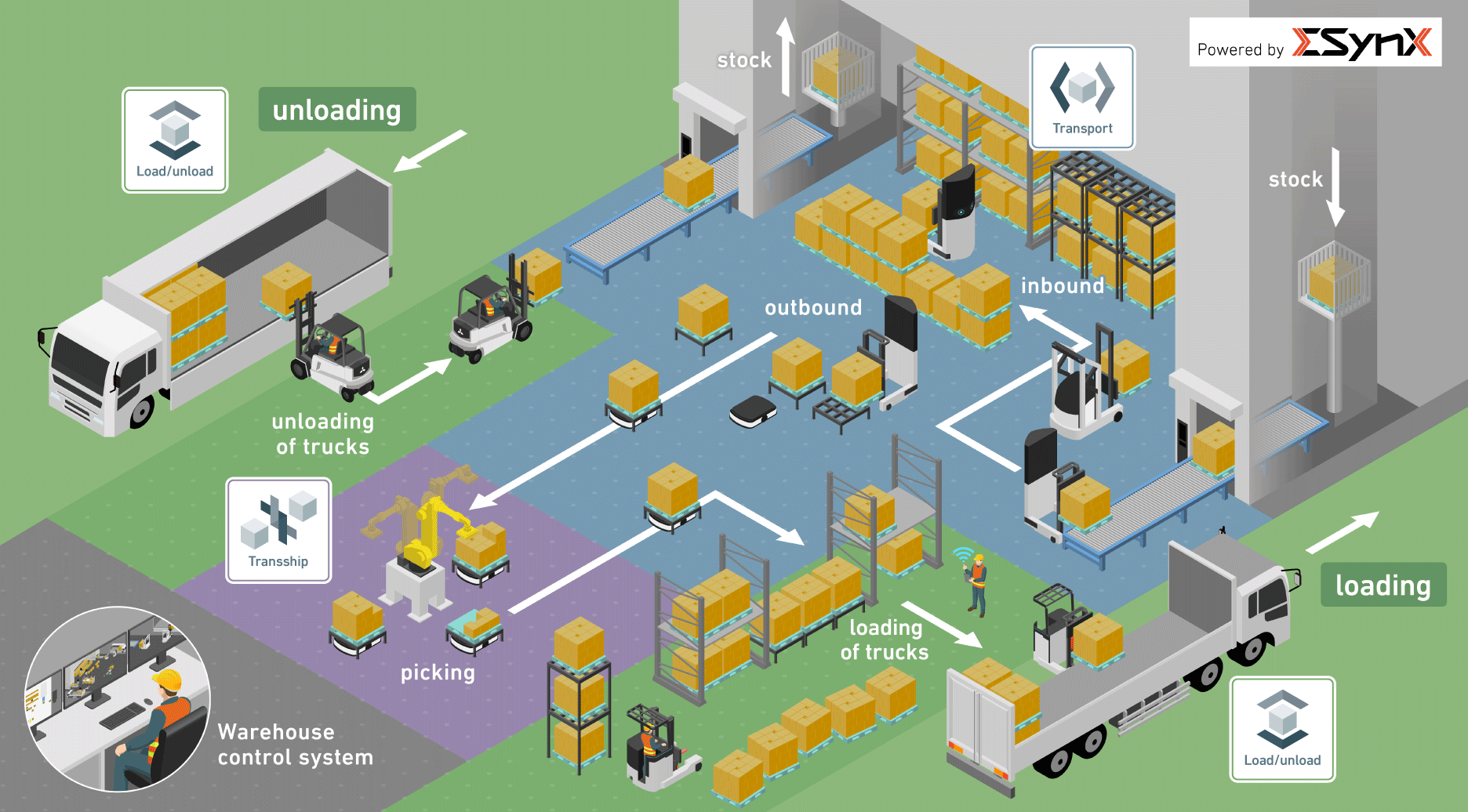

MHI is proposing intelligent logistics solutions to address this situation, utilizing ΣSynX® (Sigma Syncs), a platform that realizes smart mechanical systems and enables optimal human-machine collaboration, as a core.

ΣSynX integrates and links diverse logistics equipment in warehouses regardless of the manufacturer, and also realizes human-machine collaboration. This will enable intelligent logistics optimized for each customer's site conditions and challenges and contribute to solving industry-wide issues.

Concepts of Utilizing ΣSynX in Logistics field

Intelligent logistics solutions utilizing ΣSynX are based on the following three concepts to accelerate solutions to issues in logistics.

Implementation of know-how of skilled workers

Experienced workers in logistics have know-how, such as determining optimal location areas for packages and efficient rearrangement (Note). By implementing this expertise in our unique optimization engine and integrated control system equipped with ΣSynX, we can achieve more efficient automation beyond mere automation.

(Note) Moving packages or products arranged in one place in a certain way to another place or changing their arrangement.

Man-machine collaboration

In our solutions, the system centrally manages the work of both humans and machines, achieving safe collaborative work and labor saving at the same time. Since it enables coordination between humans and machines, partial or phased introduction/implementation of the system is possible, such as automating only part of the workflow.

Lean and agile implementation

When introducing our solutions, there is no need for large-scale construction or floor work, and existing facilities and assets can be utilized effectively. It is easy to change the layout and restore to the original state, so it can be introduced from a small start. The initial investment can be minimized while promoting intelligent solutions in stages.

With these three concepts, we aim to solve issues faced in logistics field, such as minimizing truck waiting time, maximizing warehouse density, increasing throughput, and responding to operator shortages.

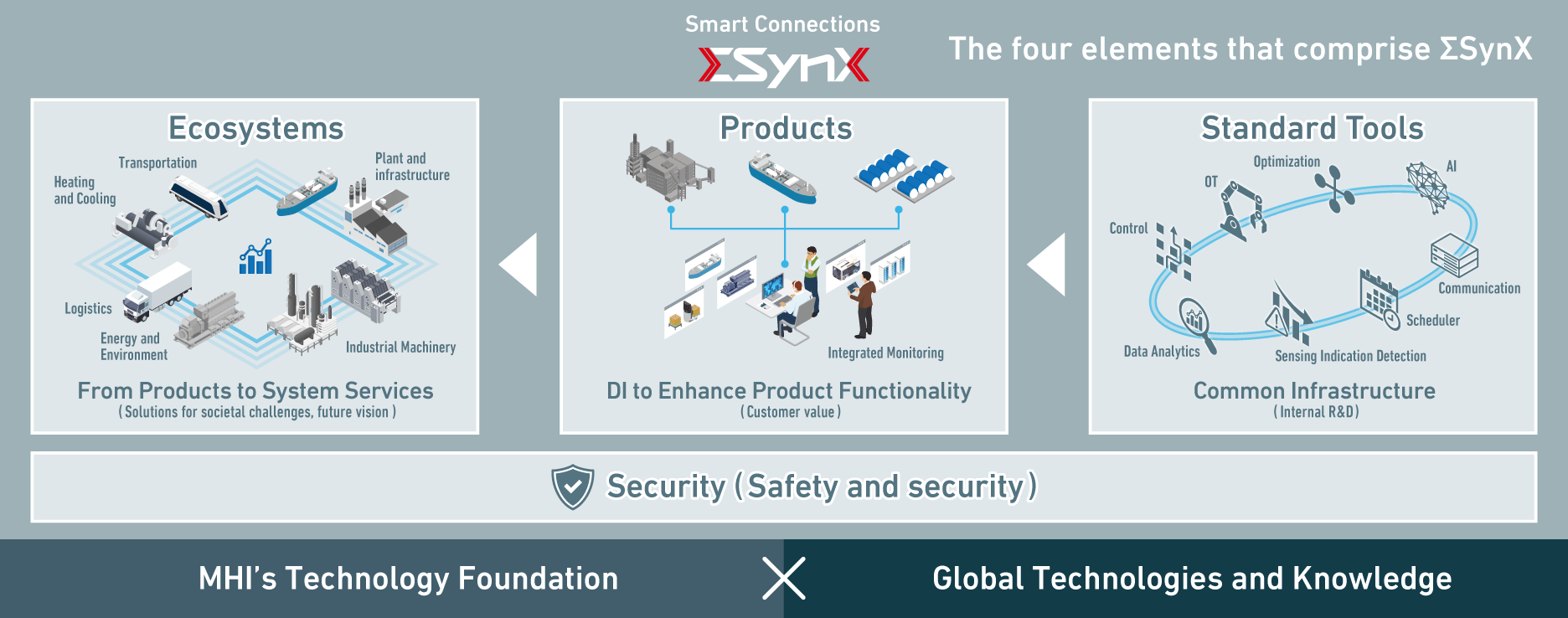

What is ΣSynX?

Our solution branded as “ΣSynX” is a digital innovation that aims for coordination between humans and machines, with the concept of “Smart Connections.”

Based on MHI’s vast data and know-how accumulated in approximately 700 technology fields, more than 500 products, thousands of machine modules, and expertise in 31 business areas, ranging from development to operation and maintenance of complex machinery, ΣSynX is aimed to create new value by combining technologies and expertise from around the world.

By promoting the intelligent and autonomous machine systems not only in the logistics industry but also in a variety of other industries, we strive to build an industrial ecosystem, develop intelligent products and services, and achieve higher levels of security.

Related Information

Related Products and Services

Related Articles from Spectra - Our Online Magazine

Related Press Releases

- Mitsubishi Logisnext to Demonstrate Automated Forklift Equipped with "SynfoX" at "4th INNOVATION EXPO"-- Contributing to Warehouse Automation Using MHI's "ΣSynX" Elemental Technologies --

- MHI's Automated Picking Solution Utilizing ΣSynX Fully Implemented at Kirin Group's Ebina Logistics Center, the First Such System in Japan

- MHI and Mitsubishi Logisnext to Display "ΣSynX" Products Enabling Autonomous and Intelligent Warehouse Logistics

- ΣSynX "Smart Connections" Provides Solutions for the Various Challenges Facing Society

- MHI to Provide the "ΣSynX Supervision" Remote Monitoring Service as a Digital Innovation Brand

- MHI and Mitsubishi Logisnext to Commence Provision of Automated Picking Solutions for Warehouses Based on “ΣSynX”