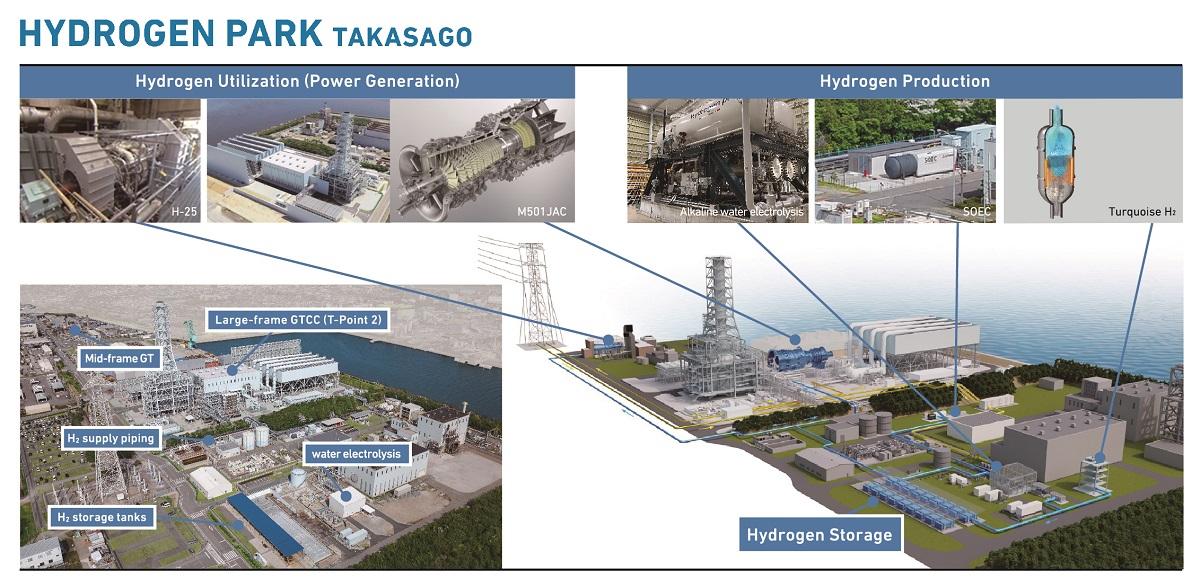

Takasago Hydrogen Park, the World's First Integrated Validation Facility from Hydrogen Production to Power Generation

MHI Group’s Takasago Hydrogen Park is the world's first integrated hydrogen validation facility for testing technologies from hydrogen production to power generation, aiming for early commercialization of hydrogen gas turbines. It was built within MHI's Takasago Machinery Works in Hyogo Prefecture in west central Japan for the purpose of improving product reliability through technological validation and contributing to the implementation of hydrogen power generation and production technologies in society. The park is working on successive expansion of next-generation hydrogen production technologies and demonstrating hydrogen co-firing and 100% hydrogen firing of gas turbines.

The park is divided into three areas: hydrogen production, storage, and utilization. In the Hydrogen Production area, we installed and began operating an alkaline water electrolyzer manufactured by Norway’s HydrogenPro AS, which has one of the world’s largest hydrogen production capacities of 1,100Nm3/h, in 2023. The hydrogen produced at the facility is stored in hydrogen storage tanks installed in the Hydrogen Storage area. Actual verification of hydrogen combustion is conducted using a large frame JAC gas turbine (450MW class) at the combined cycle power plant validation facility and a small to medium-sized H-25 gas turbine (40MW class) that had been previously installed to drive a compressor at the combustion test facility, both of which are located in the Hydrogen Utilization area.

For hydrogen production, we are developing our own technologies such as SOEC (Solid Oxide Electrolysis Cell), AEM(Note) electrolyzer, and turquoise hydrogen which means hydrogen generated without CO2 emission by pyrolysis of methane into hydrogen and solid carbon. Elemental technologies are developed at Nagasaki Carbon Neutral Park and then verified and demonstrated under actual operating conditions. Takasago Hydrogen Park is our important development base for realizing a hydrogen solutions ecosystem by building a value chain of production, storage, and utilization.

(Note): AEM: Anion Exchange Membrane

A Development Base for Key Technologies in Decarbonizing Energy, Nagasaki Carbon Neutral Park

MHI launched operations of Nagasaki Carbon Neutral Park, as a central base dedicated to technology development in decarbonizing energy. Located in Nagasaki city in Japan, this facility’s R&D, design, and manufacturing departments work together aiming for commercialization of products and technologies. The Nagasaki District Research & Innovation Center, a symbol of this facility, is where R&D is conducted including elemental technologies for hydrogen production, biomass synthetic fuel production, ammonia combustion and CO₂ capture.

At Nagasaki Shipyard & Machinery Works, we are accelerating R&D toward commercialization and practical application by leveraging the design and manufacturing functions and expertise of thermal energy equipment cultivated both at the Nagasaki plant which is responsible for design and manufacturing, and the Koyagi plant which assumes manufacturing. Key technologies developed at Nagasaki Carbon Neutral Park are subsequently verified at hydrogen production and power generation validation in conjunction with hydrogen gas turbines at our Takasago Hydrogen Park, a hydrogen production and power generation validation facility. This series of process from elemental technology development to validation at a commercial operation-level leads to improved reliability of the developed products once they are brought to market.

Related Information

Related Articles from Spectra - Our Online Magazine

Related Press Releases

- MHI Starts a Study on Optimizing the Decarbonization Value Chain Using Green Hydrogen and Ammonia Exported from India - Initiative under METI's "The Global South Future-Oriented Co-Creation Program"

- Construction Begins on Hydrogen-Based Ironmaking Plant in Linz, Austria

- MHIET Launches 450kW Gas Cogeneration System Capable of Hydrogen Co-Firing as Reliability Verified through Demonstration Testing

- 50% hydrogen blend testing successfully completed at Georgia Power’s Plant McDonough-Atkinson in US

- Approval in Principle (AiP) for the Basic Design of a Large Ammonia-Fueled Ammonia Carrier Obtained

- MHI Successfully Achieves 1,200 Hour Milestone in Durability Test on Ultra-High-Pressure Liquid Hydrogen Booster Pump

- MHI Invests in Koloma, a US-Based Geologic Hydrogen Exploration Startup

- MHI and Taiwan Fertilizer Sign MoU for Joint Study on Developing Fuel Ammonia Value Chain in Taiwan