Technologies and Products Lineups

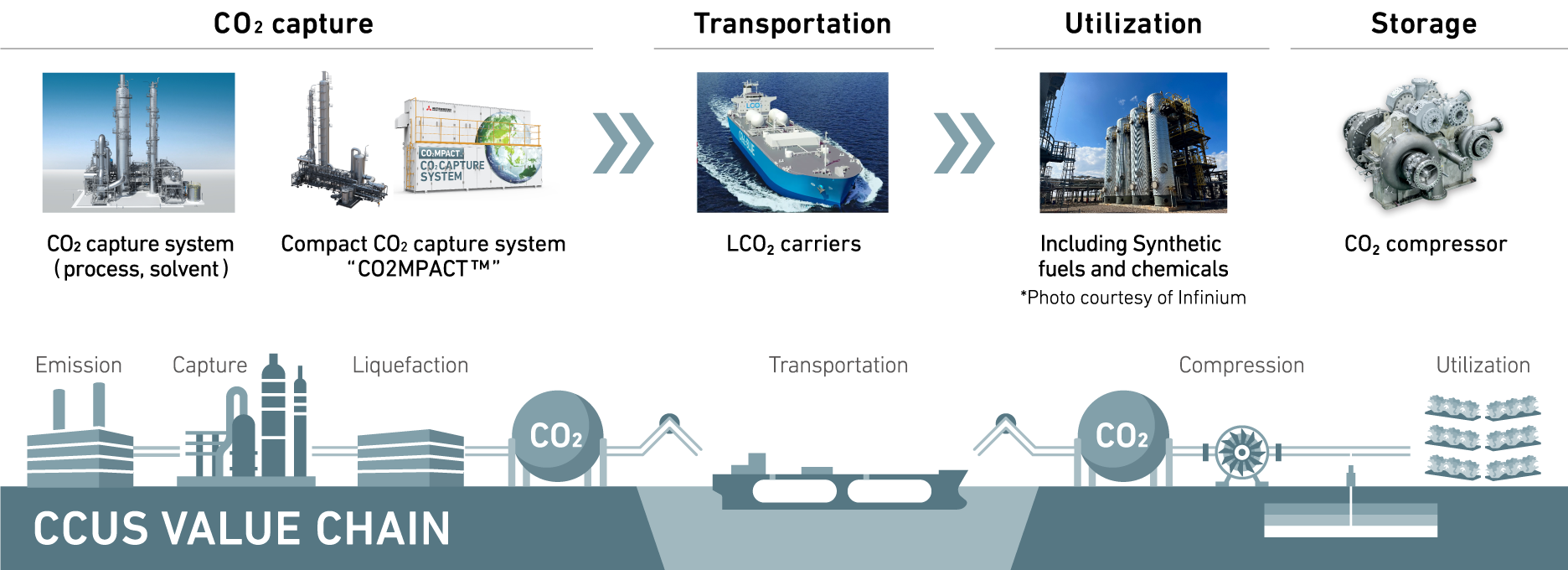

MHI Group provides essential technologies and products related to CCUS, including CO₂ capture, transportation, and compression.

To establish a CCUS value chain, we are expanding our lineup of products related to CCUS, such as state-of-the-art CO₂ capture technologies, large-scale CO₂ capture plants and small- and mid-sized CO₂ capture system in the CO₂MPACT™ series, liquefied CO₂ (LCO₂) carriers, and compressors. At the same time, we are working on further leveraging our technologies, in the fields such as developing larger-sized LCO₂ carriers that will be required as the market expands, as well as advanced technologies in CO₂ compression.

Cost-effective and Highly Efficient CO₂ Capture Technology from Variety of Flue Gas Sources

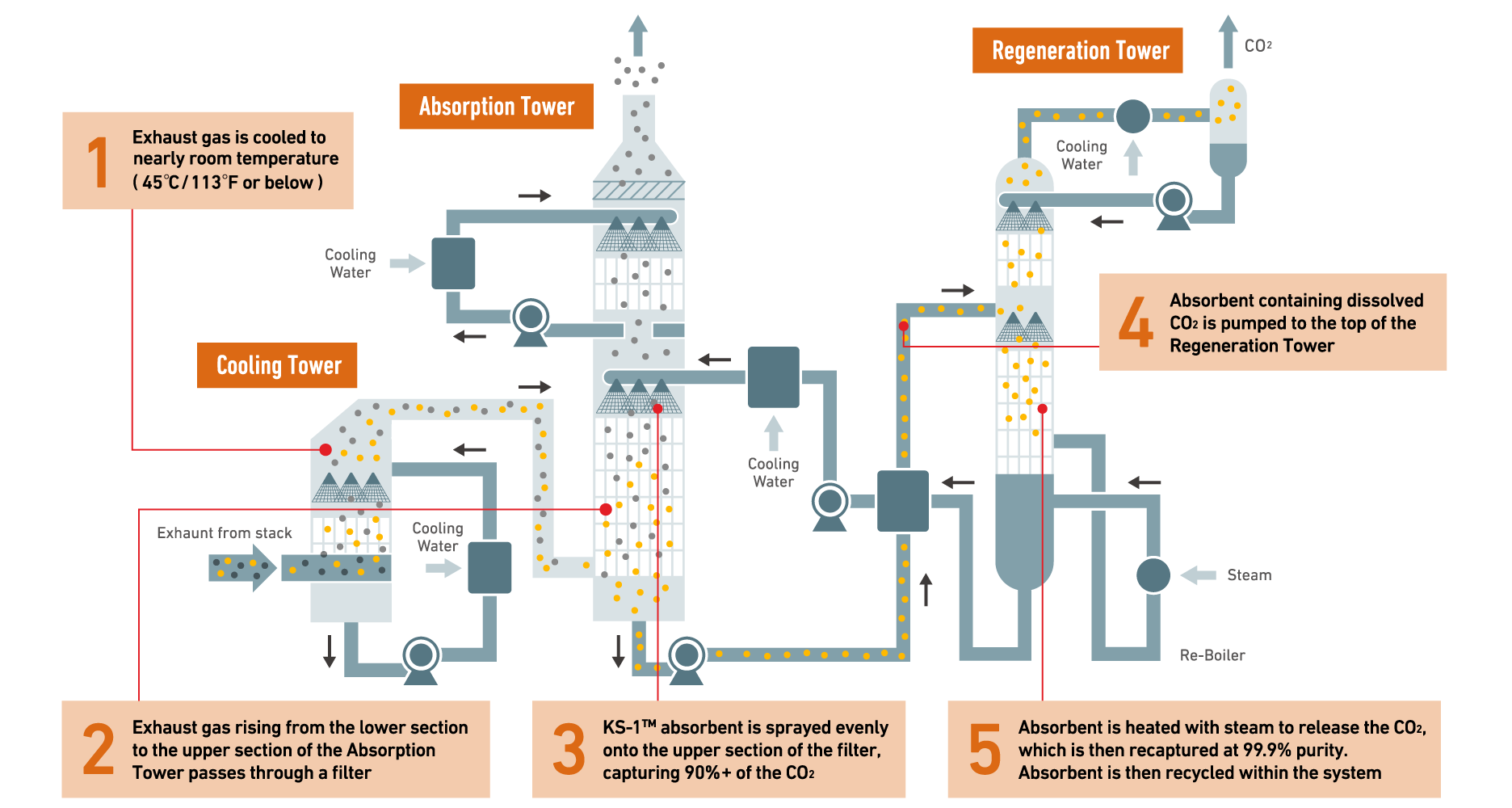

MHI Group has been developing CO₂ capture technology for more than three decades. One of the outstanding results of our efforts is the KM CDR Process™(Kansai Mitsubishi Carbon Dioxide Recovery Process), a proprietary CO₂ capture technology that can handle a variety of Flue Gas sources and a wide range of volumes, from small to large plants.

In the 1990s, MHI started joint research and development for CO₂ capture technologies with Kansai Electric Power Company (KEPCO), and delivered the first commercial plant using the KS-1™ amine solvent in 1999. Since then, the solvent has been delivered to 18 plants all over the world (as of September 2024), earning the top global market share. This process can capture more than 90% of the CO₂ contained in the target gas (with a purity of more than 99.9% by volume) and reduces steam consumption as well thanks to our original energy-saving regeneration system.

Also, in order to address needs such as advanced energy-saving performance, reduced operating costs, and lower environmental impact, MHI along with KEPCO developed the new KS-21™ solvent and the state-of-the-art Advanced KM CDR Process™ that uses KS-21™.

Furthermore, to respond to needs for CO₂ reductions in smaller industrial facilities, MHI offers the CO₂MPACT™ series of small and mid-sized CO₂ capture systems that can be installed easily and deployed faster.

A Compressor that Meets Customers’ Requirements for CO₂ Capture, Transport and Storage

Gas re-injection compressors are used for handling high-pressure, high-density gas which is sent deep underground to an oil or natural gas well. MHI Group offers a wide range of compressors suitable for use in CO₂ capture systems for industrial operations, as well as the transportation of captured CO₂ by pipeline and CO₂ storage and has particularly significant experience with the continuous duty CO₂ compressors.

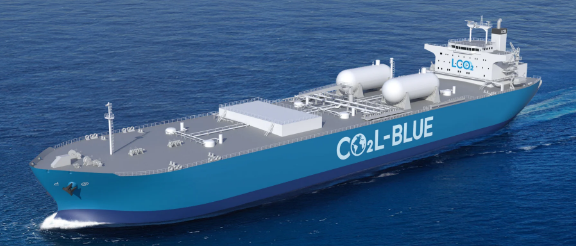

Maritime CO₂ Transportation Solutions Support the Transition to Low Carbon Economy

Liquefied CO₂ carriers (LCO₂ carriers) are vessels specially designed to efficiently transport liquefied carbon dioxide at low temperatures and high pressure by sea to the location of storage or usage. These carriers are a safe and economical option for transporting carbon dioxide produced by power plants, steelworks, and chemical factories.

MHI Group has been building ships since 1857 and has extensive experience with the design and construction of LNG and LPG carriers. MHI is now taking its expertise in shipbuilding to supplement the transport and handling of cryogenic liquefied gases and applying it to LCO₂ carriers.

MHI Group has been building ships since 1857 and has extensive experience with the design and construction of LNG and LPG carriers. MHI is now taking its expertise in shipbuilding to supplement the transport and handling of cryogenic liquefied gases and applying it to LCO₂ carriers.

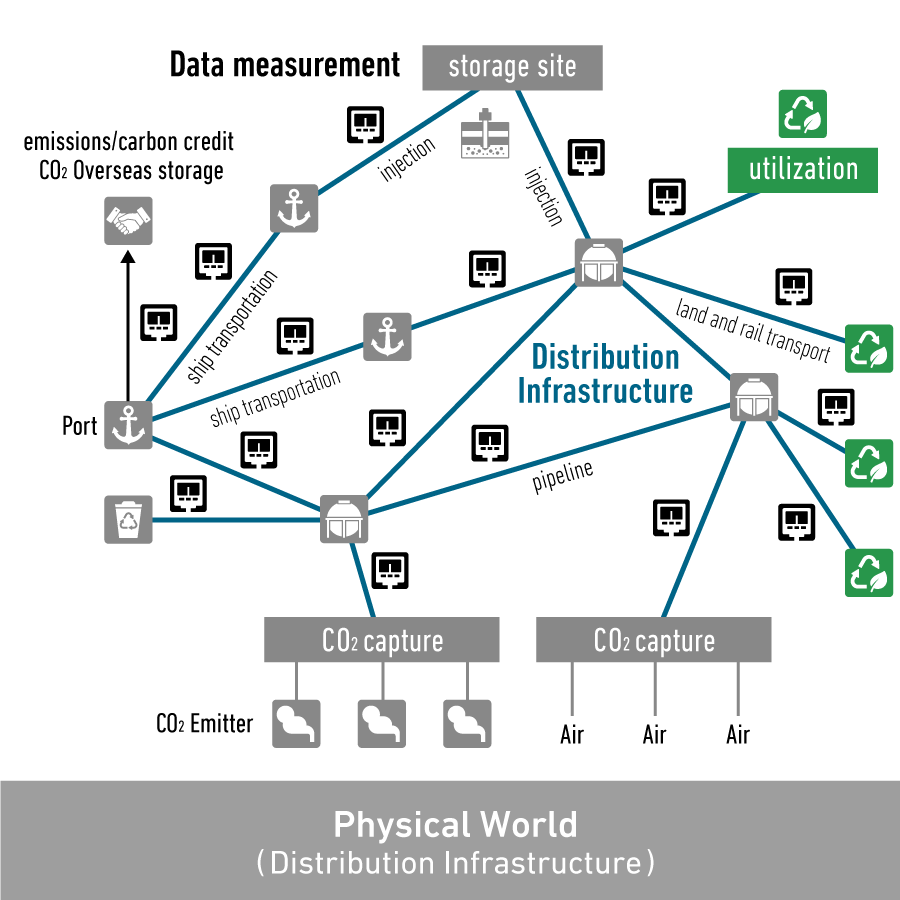

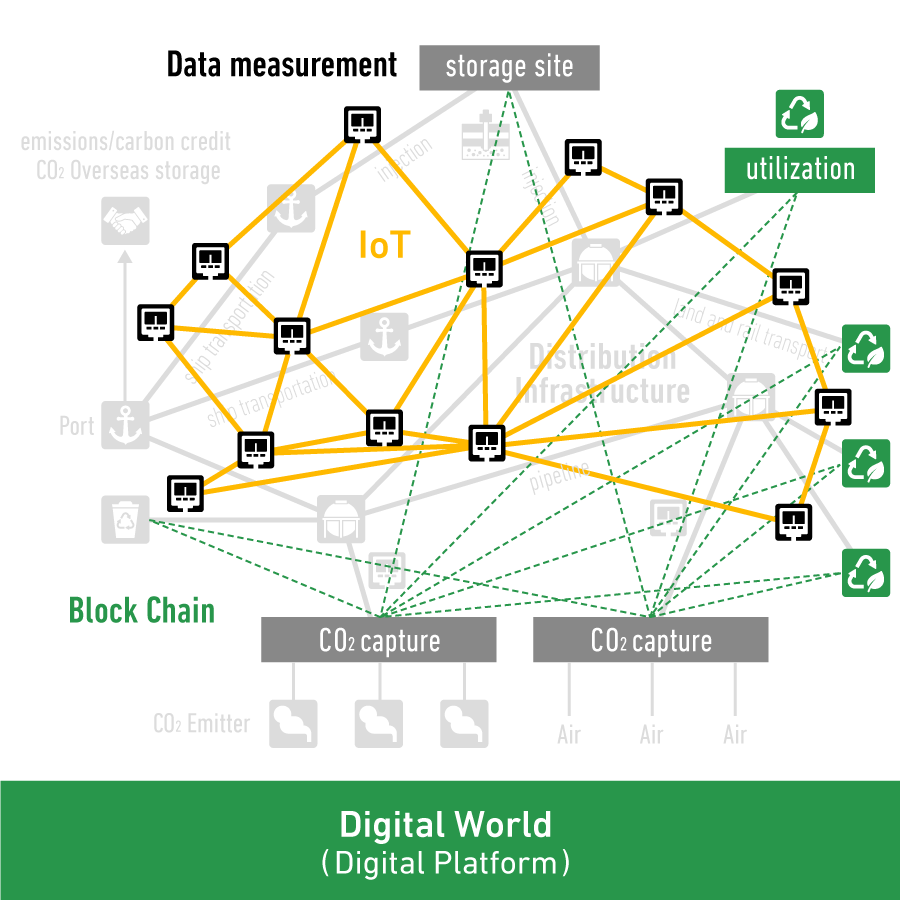

Digital Platform: CO₂NNEX®

MHI is developing “CO2NNEX® Digital Platform for visualization of the CCUS value chain, accelerating the actions towards the realization of a carbon neutral society. By enabling the management of track records (traceability) of CO₂, management and transfers of the environmental value entailed in CO₂(Note), visualization and streamlining of the CO₂ supply chain, efficiently matching CO₂ suppliers (emitters) with its users and adjusting the balance between demand and supply, aligning both the digital layer and physical layer, we will realize optimization of the entire value chain and maximization of the CO₂ transaction.

(Note) This environmental value refers to the value of not increasing the CO₂ in the atmosphere.

Related Information

Related Products & Solutions

Related Articles from Spectra - Our Online Magazine

Related Press Releases

- CO₂NNEX® Digital Platform for Transfer and Management of e-Methane Clean Gas Certificates to Be Utilized in Nagaoka Methanation Demonstration

- MHI Awarded Contract for Basic Design of Japan's Largest CO₂ Capture Plant at Hokkaido Electric Power's Tomato-Atsuma Power Station

- Acquired Approval in Principle (AiP) for World's First LCO₂/Methanol Carrier

- MHI Starts Operation of New CO₂ Capture Pilot Plant at KEPCO's Himeji No.2 Power Station

- MHI Awarded a Study on CO₂ Capture Modules for Floating Production Storage and Offloading vessels (FPSOs)

- Mitsubishi Shipbuilding Acquired Approval in Principle (AiP) for the Basic Design of an Onboard Carbon Capture and Storage System

- MHI Establishes Branch Office in Perth, Western Australia, Focused on Decarbonization Business, Accelerating Business Developments in Hydrogen, Ammonia and CCUS

- World-first Trial of New Technology to Recycle CO₂ Emissions from Steel Production Begins at ArcelorMittal Gent, Belgium