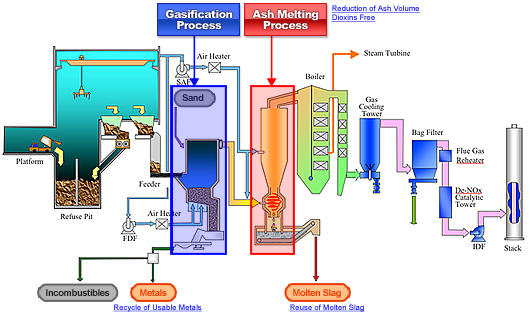

Mitsubishi MSW Gasification & Ash Melting System

Mitsubishi MSW Gasification & Ash Melting System

We, Mitsubishi Heavy Industries Environmental & Chemical Engineering Co., Ltd., are a world leading engineering company in the field of Waste to Energy (WtE) system and have delivered and constructed more than 180 WtE plants since 1964.

As an Advanced WtE system for new generation, we successfully developed the "Mitsubishi Municipal Solid Waste (MSW) Gasification & Ash Melting System" in 1998 based on its rich technical knowledge and R&D capability, and constructed the first commercial plant in Kushiro city, Japan, in 2006.

This first commercial plant is located nearby Kushiro Shitsugen National Park registered as the site of Ramsar Convention and has been operated successfully as the advanced and most environmental friendly WtE system.

| Waste treatment capacity | 240 t/day (120 t/day × 2 units) |

|---|---|

| Electric generating capacity | 4.6 MW |

| Waste type | Municipal Solid Waste |

| Dioxins at the stack | 0.00011 to 0.0055 ng-TEQ/Nm3 |

| Annual operation | more than 280 days |

Major Advantages

Major advantages of Mitsubishi MSW Gasification & Ash Melting System are as follows.

- Only 3percent residual(Note1) as a form of fly ash remains : process of gasification and ash melting can perform high recyclability compared to conventional incineration system. (Note1:residual ratio depends on components of waste)

- Dioxins free system: not only in emission gas but also in melted ash by-product as construction material, our System performs extremely high level control for Dioxins emission.

- Metals (aluminum,iron and steel) contained in waste can be recovered and recycled with rather high sales value compared to metals from conventional incineration.

- Dioxins free melted ash or molten slag can be used for construction material such as road bed material and can be used and mixed as alternative material to aggregate in concrete works.

System Flow

System flow of Mitsubishi MSW Gasification & Ash Melting System is as follows.