Car Crash Simulator

Distributors :

Outline of Product

Shortens R&D Periods and Reduces R&D Costs.

Collision data have so far been obtained by colliding expensive real cars in motor vehicle collision experiments. The Car Crash Simulator by Mitsubishi Heavy Industries Machinery Systems, Ltd. is a nondestructive test system adopting an electrohydraulic servo controlled by computer. The system tests with extremely high precision at low cost. Research and development for seats, seat belts, air bags, doors, automobile interiors, etc. can be carried out in short periods with little expense.

Feature

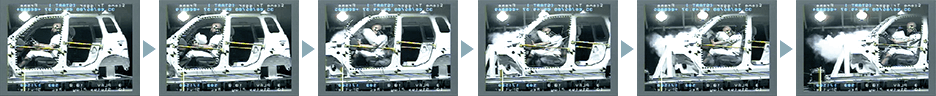

The Car Crash Simulator accurately reproduces the behavior of the occupants in a vehicle during collision and measures and evaluates injuries.

- Meets the Global Test Criteria

- A single system simulates collisions onto the front, side, and (low speed) back of a vehicle using the original technologies of Mitsubishi Heavy Industries Machine Systems. Simulations with the system cover global standard test criteria, including those of Japan, the United States, Europe, China, and elsewhere.

- High Precision

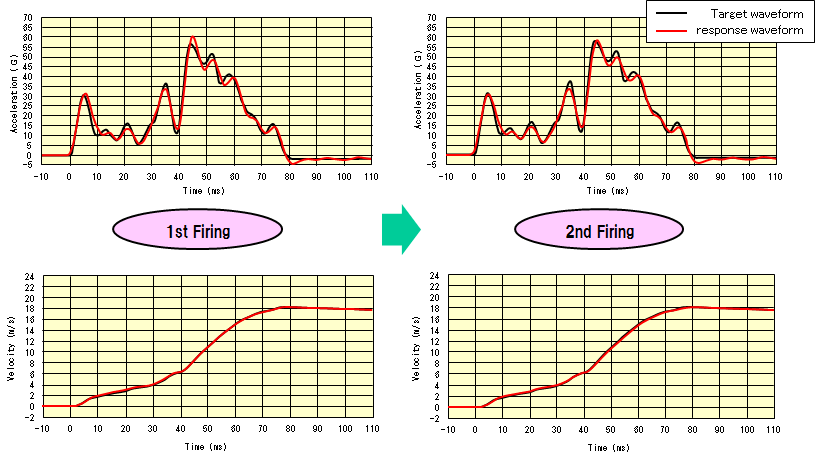

- High-precision test can be carried out with one or two shoots without destroying the vehicle. Development costs are significantly reduced.

- Automatic Test

- Easy and automatic testing. The development period is shortened for active and passive occupant-protective devices such as safe seats, child seats, seat belts, air bags, head rests, pre-crush brakes, interiors, etc.

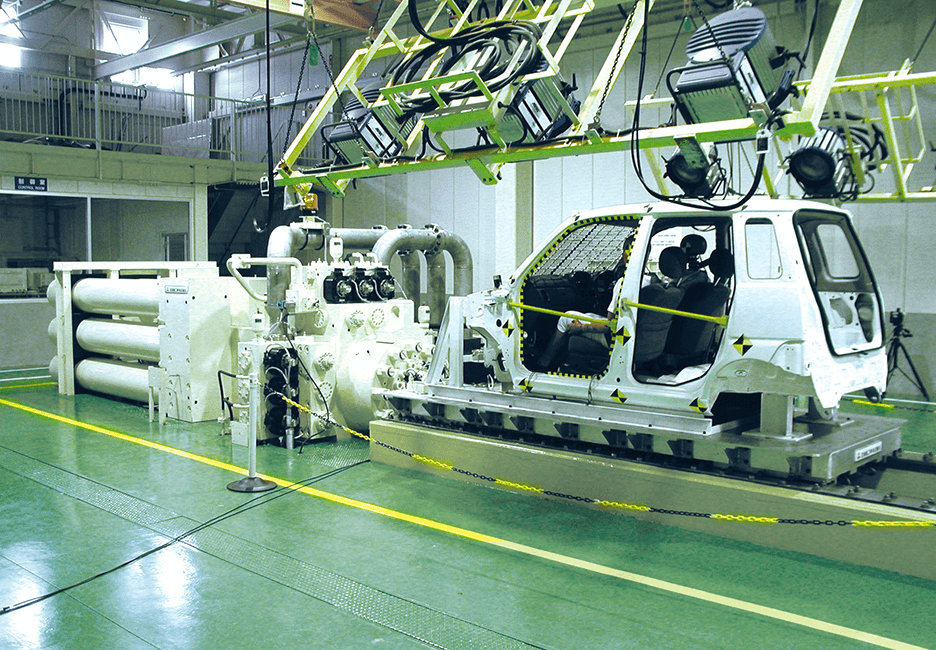

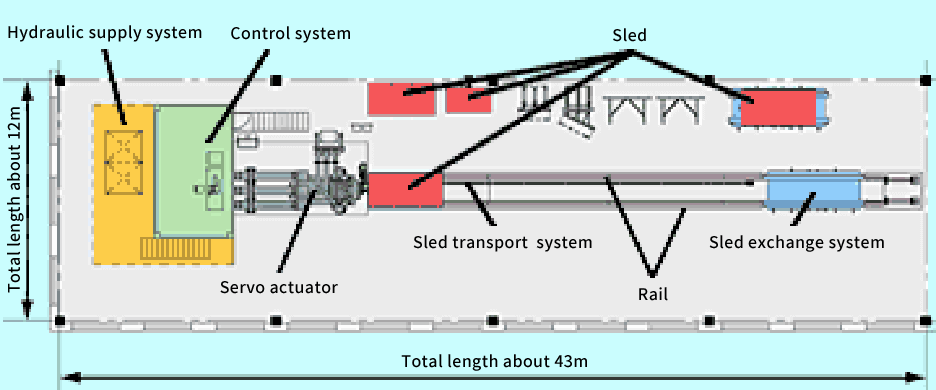

System

The The Car Crash Simulator is composed of a control system, servo actuator, sled, rail, sled moving device, sled switching device, hydraulic supply system, etc.

Working Principle

The test vehicle is loaded onto the sled and accelerated in a backward-facing position by the hydraulic actuator.

The crash test dummy is subjected to the same impact shock that would be delivered in an actual collision

Pitching System to Realistically Reproduce Collision Phenomena

The pitching System is capable of synchronizing control of acceleration in the floor direction of an arbitrary waveform, pitch angle, and up-and-down motion to realistically reproduce collision phenomena. When the pitching device is not in use, the whole device is retracted below the floor surface for operation in a barrier-free state.

Examples of Application in Other Fields

- Development of occupant-protective devices for busses and trucks

- Development of seats and occupant-protective devices for aircrafts (FAA, etc.)

- Impact tests for various types of measuring instruments, electronic equipment (personal computers loaded into a vehicle, etc.), occupants, etc.

- General impact test (MIL-STD-810, etc.)

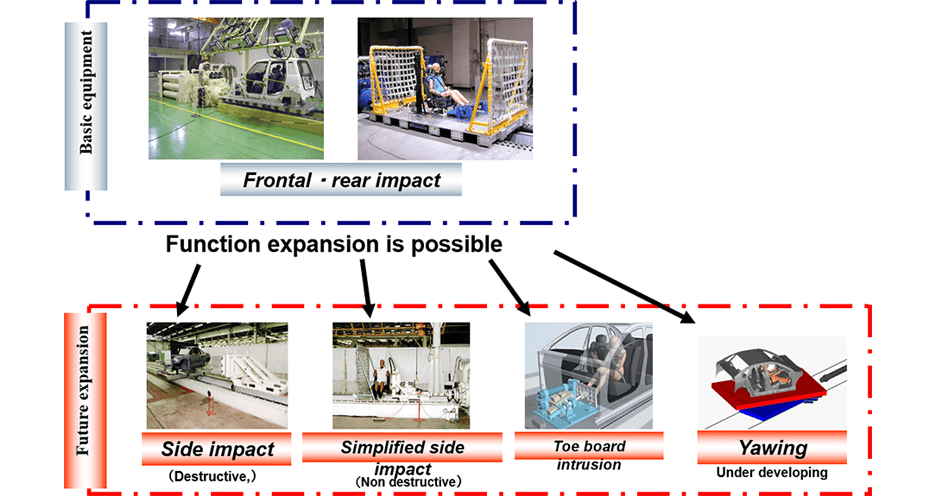

Evolvability and Extendibility of Car Crash Simulator

The holy grail for car manufacturers is to dramatically decrease the number of real car crash tests by equipping the three big options of pitching, intrusion, and yawing in a motor vehicle collision simulator. A simulator of this type will allow them to bring collision-safe cars to the market at early dates and low prices.

Mitsubishi Heavy Industries Machine Systems will steadily work towards commercialization to deliver these options in the post-installation phase.

Technology

Principal Performance of the Motor Vehicle Collision Simulator

Slide horizontally to see the table.

| Basic Specification Item | Specification Value | Remarks | |

|---|---|---|---|

| Front face collision simulation | Payload | Max. 2,000 kg | White body, surface plate, measuring instruments, etc. |

| Firing accelaration | Max. 80 G | When payload of 1,500 kg is equipped | |

| Firing velocity | Max. 25m/s | = 90 km/h | |

| Simplified side impact simulation | Door Firing accelaration | Max. 85 G to min. -30 G | When the maximum payload of 750kg is equipped |

| Door Firing velocity | 16m/s at maximum | ||

| Side face collision simulation | Load weight | 2,000 kg at maximum | Equivalent to MDB (FMVSS) |

| Impact velocity | 21m/s at maximum | Speed at MDB displacement of 3,000 mm | |

Examples of Frontal Test Results

The acceleration waveform of a real car crash test can be faithfully reproduced from the first shoot.