Press Information

・ Anticipated to achieve 0.27kg-CO2/kWh CO2 emission coefficient with hydrogen admixture in cogeneration system for power and steam

・ To contribute to low carbonization of distributed KU gas engine power generation system (3.65 - 5.75 MW) for wide variety of industries

・ Aiming for marketing hydrogen blend-fired KU series gas engines in FY2025

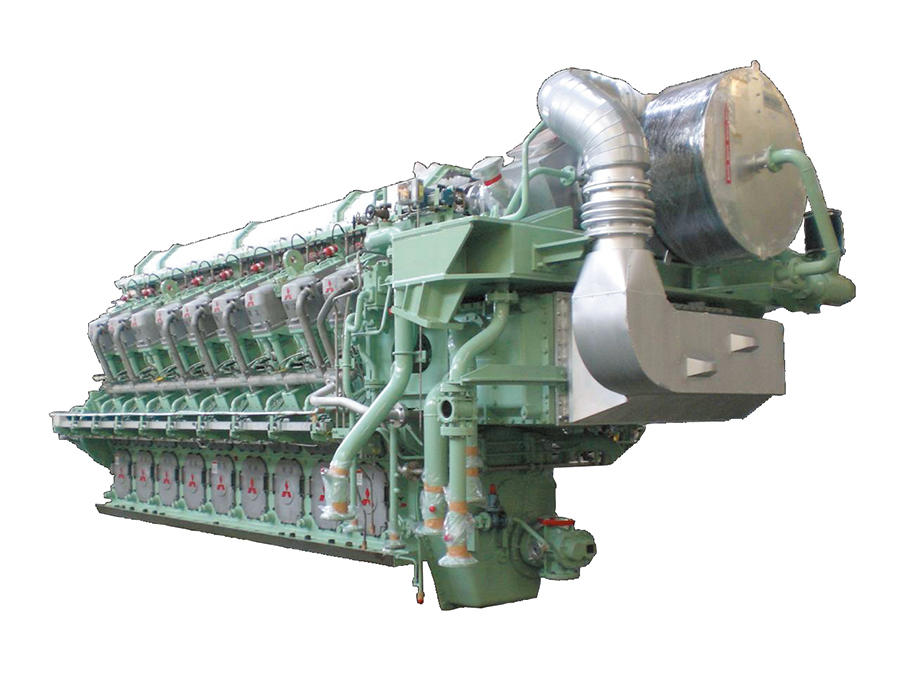

KU Series Gas Engine (18KU30GSI)

Tokyo, November 1, 2023 - Mitsubishi Heavy Industries Engine & Turbocharger, Ltd. (MHIET), a part of Mitsubishi Heavy Industries (MHI) Group, confirmed stable combustion of hydrogen admixture through a testing of a single cylinder engine. The test achieved stable combustion with up to 50 vol% hydrogen admixture without losing the rated output. In preparation for targeted commercialization in FY2025, MHIET will finalize specifications of auxiliary equipment to be installed together with the engine and control systems of all related equipment.

The testing constitutes a part of the attempt to achieve MHI Group's MISSION NET ZERO, net zero CO2 emissions from the entire Group by 2040. MHIET has been focused on development and commercialization of hydrogen engines, which is listed as a key strategy in its roadmap to carbon neutrality(Note1). The test was performed aiming for altering the KU series gas engine cogeneration system, a widely used system in various industries, into a system of less carbon emissions while maintaining output.

In this testing, MHIET team tackled issues such as engine knocking caused by hydrogen's faster flame propagation speed and preignition combustion caused by lower minimum ignition energy of hydrogen(Note2) and succeeded in maintaining stable combustion by adjusting the excess air ratio and other parameters. Consequently, the team verified stable combustion of hydrogen admixture of maximum 50 vol% with keeping the rated output. It suggests the cogeneration system with the original 5.75 MW engine would generate the same result.

Furthermore, the testing revealed that the cogeneration system that generates power and steam is likely to satisfy CO2 emission coefficient of 0.27kg- CO2/kWh without recovering energy for hot water. The emission level is set as the standard for natural gas-fired power generation system during transitional period by EU taxonomy for sustainable activities(Note3) . It was previously confirmed that other specification of KU gas engine cogeneration system that generates steam utilizing exhaust gas and higher temperature engine cooling water (120°C jacket water at engine outlet) has nearly met the standard already. The team expects that the CO2 emission coefficient of this system specification will be further reduced by fueling hydrogen blend, and they continue to work on the development.

KU series gas engine cogeneration system is a proven product that has been used by many customers all over the world. The modification to GSI, retrofitting with an updated ignition system, can bring higher energy efficiency and lower CO2 emission, which has been contributing to the sustainable operation of existing facility. Likewise, new installation of GSI would make it easier to rework for hydrogen blend fuel. For the growing needs of hydrogen as a means to carbon neutrality in mid to long term, MHIET will expedite marketing of KU and other gas engine products that are fueled by hydrogen mixture or pure hydrogen, to offer expanded options to achieve low carbon or zero carbon society.

- 1Please visit the following page for the roadmap to carbon neutrality:

https://www.mhi.com/group/mhiet/feature/sdgs - 2Types of abnormal combustion. Knocking occurs when the fuel-air mixture self-ignites in the case that the ignition timing is too early or the compression ratio is too high, resulting in a rapid rise in the cylinder pressure. Preignition is when the fuel-air mixture self-ignites prior to ordinary ignition, causing the pressure inside the combustion chamber to rise rapidly. Both could damage internal components if they frequently occur.

- 3As per COMMISSION DELEGATED REGULATION (EU) 2022/1214 of 9 March 2022 amending Delegated Regulation (EU) 2021/2139 as regards economic activities in certain energy sectors and Delegated Regulation (EU) 2021/2178 as regards specific public disclosures for those economic activities, dated July 15, 2022.

Related documents of gas cogeneration system products and use of hydrogen

◆Development of gas engine cogeneration system that help achieve carbon neutral society

- Mitsubishi Heavy Industries Technical Review Vol.60 No.2 (2023)

CO2 Reduction by Gas Engine Cogeneration System (Combined Heat and Power)

◆Technical Evaluation of Hydrogen Engine Generator Set (Press Release)

- July 6, 2023

MHIET to Install 100% Hydrogen Engine Generator Set for In-house Evaluation

About MHI Group

Mitsubishi Heavy Industries (MHI) Group is one of the world’s leading industrial groups, spanning energy, smart infrastructure, industrial machinery, aerospace and defense. MHI Group combines cutting-edge technology with deep experience to deliver innovative, integrated solutions that help to realize a carbon neutral world, improve the quality of life and ensure a safer world. For more information, please visit www.mhi.com or follow our insights and stories on spectra.mhi.com.