Press Information

MHIEC Receives Highest Award at 48th Outstanding Environmental Systems Awards

-- “METI Minister’s Award” Presented for Innovative V-type Stoker System Uniquely Developed by MHIEC Achieving High Efficiency and Environmental Excellence --

-- “METI Minister’s Award” Presented for Innovative V-type Stoker System Uniquely Developed by MHIEC Achieving High Efficiency and Environmental Excellence --

・ Innovations enable stable incineration and reduced volume of diverse wastes; efficient incineration using radiant heat contributes to easing environmental load

・ Incinerator downsizing enhances freedom in planning installations at sites with limited space

Awards Ceremony

Tokyo, July 27, 2022 – Mitsubishi Heavy Industries Environmental & Chemical Engineering Co., Ltd. (MHIEC), a part of Mitsubishi Heavy Industries (MHI) Group, has received the “Ministry of Economy, Trade and Industry (METI) Minister’s Award” at the 48th Outstanding Environmental Systems Awards, hosted by The Japan Society of Industrial Machinery Manufacturers (JSIM), for its newly developed stoker-type waste incinerator(Note1). The “METI Minister’s Award,” the highest award presented by JSIM, cited the incinerator’s innovative V-shaped structure and low loss on ignition(Note2). An awards ceremony was held at the Kikai Shinko Kaikan building (Minato-ku, Tokyo) on July 26.

JSIM’s Outstanding Environmental Systems Awards were inaugurated in 1974, with support from the METI (at that time, Ministry of International Trade and Industry), to promote research and development of environmental protection technologies and promote the adoption of outstanding environmental systems. Nominations for the awards are submitted by environmental system manufacturers and environmental engineering firms nationwide, and the award recipients are selected by a committee of experts based on criteria including innovativeness, economic merit and future potential. In addition to the METI Minister’s Award, other awards are presented in the names of the Director-General of METI’s Industrial Science and Technology Policy and Environment Bureau, Commissioner of METI’s Small and Medium Enterprise Agency (SMEA), and the JSIM President.

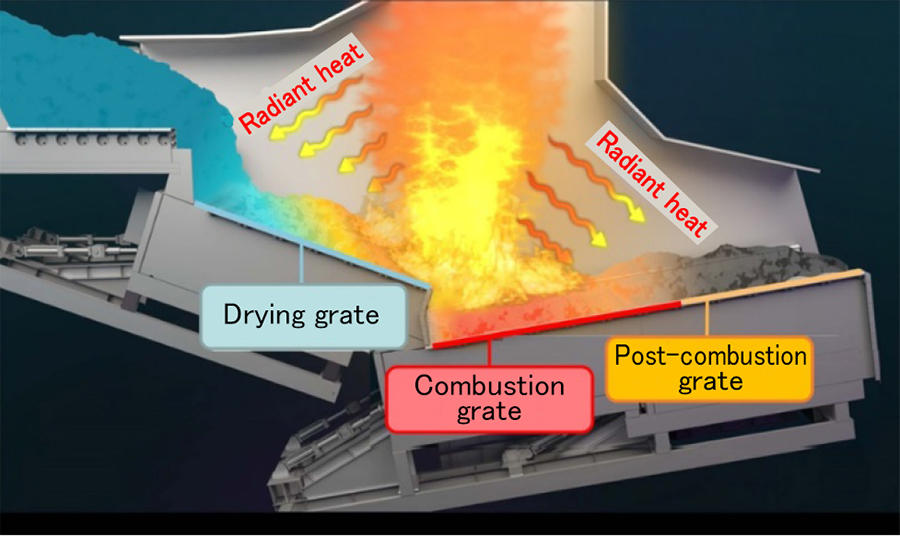

MHIEC’s V-type stoker system for waste incineration with forward acting grate-bar incorporates improvements and advances from the company’s earlier conventional type of stoker. It was developed to provide stable incineration and reduced volume of waste with wide-ranging properties and in diverse states, to contribute to reducing environmental load. The stoker structure and incinerator shape have been optimized so the surface of the stoker grates is directed at the center of the flame during all processes: drying, combustion and post-combustion. The foremost benefit derived from these innovations is the ability to receive radiant heat efficiently as the waste is combusted, enabling a reduction in the proportion of residual waste in the ash left after incineration.

Efficient use of radiant heat also enables downsizing of the stoker, saving space for boiler house which typically requires significant space within a waste-to-energy plant. These improvements enhance freedom in planning installations at sites where available space is limited. MHIEC delivered its V-type stoker system of which plant went into commercial operation in January 2021 and is operating smoothly up to today.

MHIEC has strengths in developing environmental system technologies cultivated over many years, and now, after receiving the latest JSIM award, the Company renews its determination to apply those strengths to the construction and operation of waste-to-energy plants that contribute to alleviating environmental impacts. In these ways MHIEC will make significant contributions to achieving the SDGs (Sustainable Development Goals), solving global environmental issues, and realizing a carbon-neutral society.

- 1In a V-type stoker system, waste is dried, heated, mixed and combusted as it moves along on a grid of fire grates made of heat-resistant castings.

- 2Loss on ignition represents the weight ratio of the unburnt content in the dried bottom ash.

For further information on MHIEC’s award-winning V-type stoker system:

https://www.mhi.co.jp/technology/review/pdf/e592/e592060.pdf

Innovative stoker structure and incinerator shape

enabling continuous receipt of radiant heat

About MHI Group

Mitsubishi Heavy Industries (MHI) Group is one of the world’s leading industrial groups, spanning energy, smart infrastructure, industrial machinery, aerospace and defense. MHI Group combines cutting-edge technology with deep experience to deliver innovative, integrated solutions that help to realize a carbon neutral world, improve the quality of life and ensure a safer world. For more information, please visit www.mhi.com or follow our insights and stories on spectra.mhi.com.