Mitsubishi Biomass-Coal System

Delivery record

| Sludge treatment capacity | 300 t/day |

|---|---|

| Start of Operation | November, 2007 |

Major Advantages

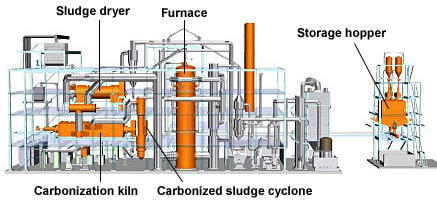

Utilization of the carbonized fuel as alternative fuel to coal

Since Lower Heating Value (LHV) of the carbonized fuel produced from the sewage sludge is more than 8,360 kJ / kg (Wet-basis), the carbonized fuel can be utilized as the alternative fuel to coal.

Safe and sanitary carbonized fuel

Since the moisture content of the carbonized fuel is approximate 15 percent, the carbonized fuel is odor free and non-self ignitable. Therefore, the carbonized fuel can be stored and transported easily and safely.

Low consumption of auxiliary fuel

Pyrolysis gas produced in the process of heat treatment in the carbonization klin can be utilized as the auxiliary fuel for carbonization klin. Therefore, low consumption of auxiliary fuel can be achieved.

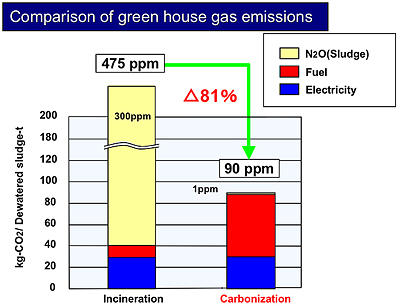

Drastic reduction of green house effect gasses

N2O emission in the flue gas can be reduced into nearly zero, because its high temperature carbonization more than 1,100 degree C. Therefore, compared with the sludge incineration system, green house effect gasses can be reduced by 80 percent.