Press Information

Toho Gas and MHIET Successfully Conduct Test Operation of City Gas and Hydrogen Mixed-fuel Combustion in a Commercial Gas Engine for a Cogeneration System

-- Rated operation at 35% hydrogen mixed fuel burning ratio a first in Japan --

-- Rated operation at 35% hydrogen mixed fuel burning ratio a first in Japan --

Tokyo, August 26, 2021 – Toho Gas Co., Ltd. and Mitsubishi Heavy Industries Engine & Turbocharger, Ltd. (MHIET), as part of a joint project to demonstrate mixed-fuel combustion with city gas and hydrogen using a commercial gas engine for a cogeneration system, have successfully conducted test operations that achieved the rated output with a 35% hydrogen mixed fuel burning ratio (by volume). This is the first such successful test in Japan(Note1).

The demonstration test was conducted at the Toho Gas Technical Research Institute in Tokai, Aichi Prefecture, using a commercial gas engine from MHIET. The aim is to acquire knowledge to facilitate city gas and hydrogen mixed-fuel combustion for existing cogeneration systems already installed at customer sites without extensive renovation of the equipment. City gas and hydrogen mixed-fuel combustion typically has issues of abnormal combustion (backfiring(Note2), knocking(Note3), preignition(Note4)), but the tests confirmed that a stable combustion state was possible by adjusting the input ratio of fuel and air, along with other modifications.

Going forward, Toho Gas and MHIET will continue to conduct research to further enhance the hydrogen mixed fuel burning ratio, contributing the advancement of hydrogen-use technologies and the realization of a hydrogen-based society.

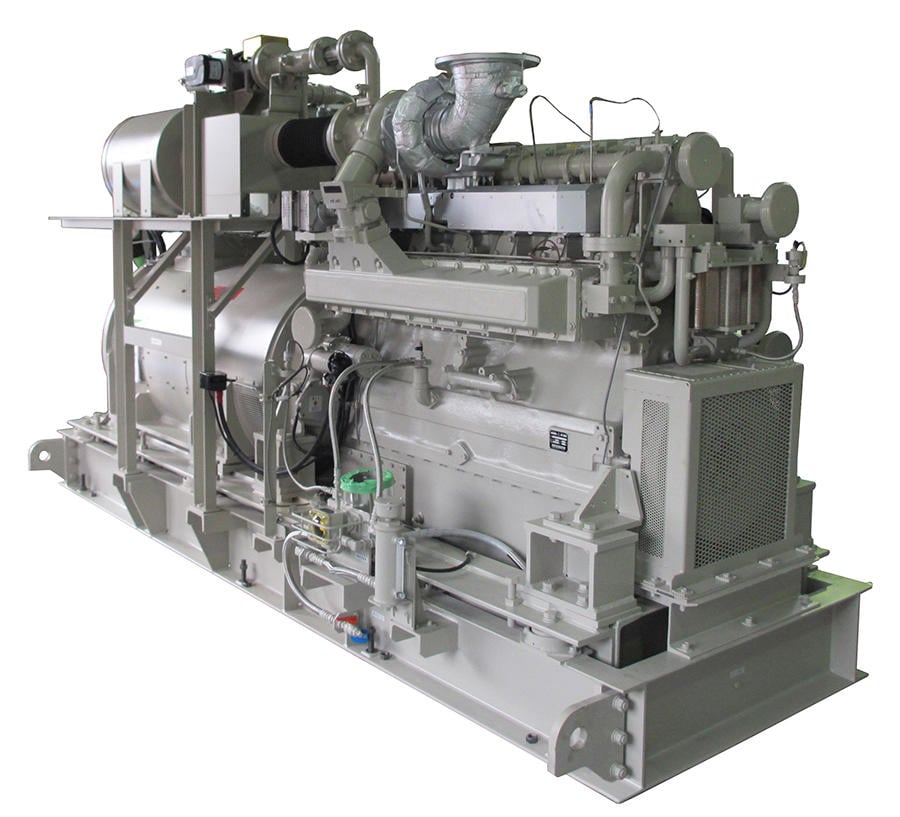

Overview of the Gas Engine Used for Test Operation

| Model | GS6R2-PTK | |

|---|---|---|

| Rated Output(Note5) | 450kW | |

| Frequency | 60Hz | |

| Generating Efficiency | 42.0% | |

- ・When operated using city gas.

- ・This gas engine model was jointly developed by Toho Gas and MHIET.

- 1 Based on research by Toho Gas.

- 2Backfiring occurs when the flame flows backward toward the inspired air flow path, resulting in damage to the engine’s intake system. Hydrogen has a smaller minimum ignition energy (MIE) value than city gas, and its burning velocity is faster, making it easier for backfiring to occur compared to single fuel firing with city gas.

- 3Knocking occurs when the ignition timing is too early, or the compression ratio is too high, and the fuel-air mixture self-ignites causing the pressure inside the combustion chamber to rise rapidly, resulting in damage to the engine’s internal components. Hydrogen has a high combustibility compared to city gas, so the cylinder pressure and temperature can easily increase, making it easier for knocking to occur compared to single fuel firing with city gas.

- 4Preignition is when the fuel-air mixture self-ignites prior to ordinary ignition, causing the pressure inside the combustion chamber to rise rapidly, resulting in damage to the engine’s internal components.Hydrogen has a smaller MIE value than city gas, making it easier for preignition to occur compared to single fuel firing with city gas.

- 5The test operations were successfully conducted at the rated output for city gas specifications.

About MHI Group

Mitsubishi Heavy Industries (MHI) Group is one of the world’s leading industrial groups, spanning energy, smart infrastructure, industrial machinery, aerospace and defense. MHI Group combines cutting-edge technology with deep experience to deliver innovative, integrated solutions that help to realize a carbon neutral world, improve the quality of life and ensure a safer world. For more information, please visit www.mhi.com or follow our insights and stories on spectra.mhi.com.