Press Information

NEGATIVE EMISSIONS PIONEER DRAX AND LEADING GLOBAL CARBON CAPTURE COMPANY - MITSUBISHI HEAVY INDUSTRIES GROUP - ANNOUNCE NEW BECCS PILOT

・ A new bioenergy with carbon capture and storage (BECCS) pilot facility will be installed within Drax's CCUS Incubation Area in the autumn.

・ The pilot facility will enable Mitsubishi Heavy Industries (MHI) to demonstrate its BECCS technology can be used at scale and help deliver against the UK's zero carbon targets.

・ The new MHI BECCS pilot will enhance Drax's technical understanding for delivering negative emissions at the UK's largest renewable power generator and help the energy company to drive forward its world-leading ambition to be carbon negative by 2030.

Drax Group and Mitsubishi Heavy Industries Engineering, Ltd., part of Mitsubishi Heavy Industries Group (MHI), have agreed a new bioenergy with carbon capture and storage (BECCS) pilot project at Drax Power Station which will get underway this autumn.

The pilot will test MHI's carbon capture technology - marking another step on Drax's journey towards achieving its world-leading ambition to be a carbon negative company by 2030.

MHI's 12-month pilot will capture around 300kg of CO2 a day for the purpose of confirming its technology's suitability for use with biomass flue gases at Drax.

Will Gardiner, Drax Group CEO, said: "Our plans to develop ground-breaking BECCS at the power station in North Yorkshire will help to boost the UK's economy following the Covid crisis and support the development of a zero carbon industrial cluster in the Humber region - delivering clean growth and protecting thousands of jobs.

"We're very pleased to be working with Mitsubishi Heavy Industries on this exciting pilot which will further our understanding of the potential for deploying BECCS at scale at Drax - taking us closer to achieving our world-leading ambition to be a carbon negative company by 2030."

Two of MHI's proprietary solvents will be tested, one of which - KS-1TM Solvent - is already being used at 13 commercial plants delivered by MHI, including Petra Nova in Texas, USA, the world's largest post combustion carbon capture facility, capturing 1.4 million tonnes of CO2 a year. The other is the newly developed KS-21TM Solvent, designed to achieve significant performance improvements and cost savings.

Kenji Terasawa, President & CEO, Mitsubishi Heavy Industries Engineering, said: "We are very proud to be a part of the BECCS pilot project with Drax. We firmly believe that our carbon capture technology would be able to contribute to the UK's zero carbon targets in a material way."

Implementing BECCS at Drax could deliver 16 million tonnes of negative emissions a year - a third of the negative emissions the UK needs from BECCS to reach its zero carbon targets by 2050 and anchor a zero carbon industrial cluster in the Humber region, delivering clean growth whilst protecting 55,000 jobs.

Nigel Adams MP, Minister of State at the Foreign and Commonwealth Office and the Department for International Development, said: "This is an exciting collaboration between Drax and Mitsubishi Heavy Industries which has the potential to further the development of technology which could help the UK achieve net zero greenhouse gas emissions by 2050 and contribute to the post-Covid economic recovery."

MHI aims to continue reducing greenhouse gases globally by providing reliable and economically feasible carbon capture technology, supported by research and development activity over 30 years and commercial records around the world.

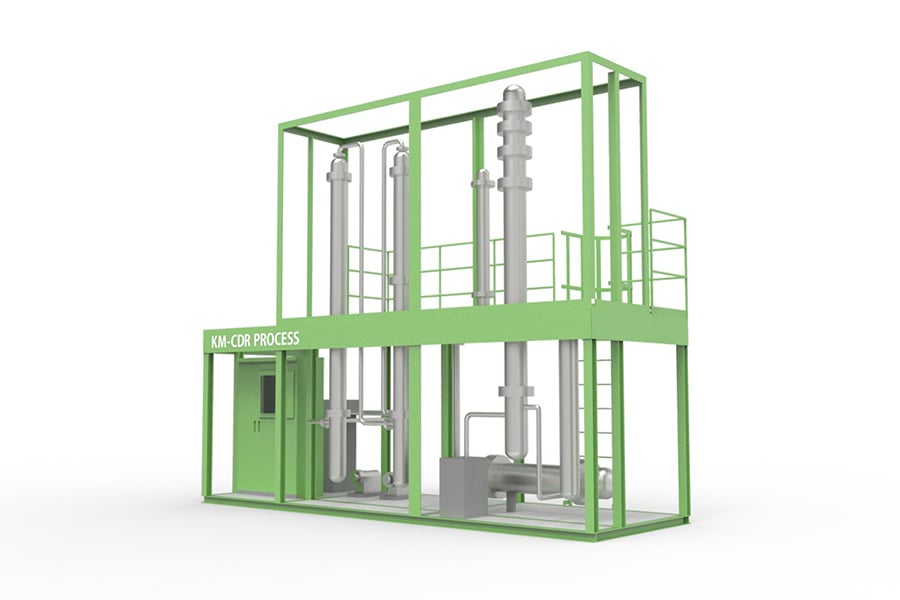

- MHI, together with Kansai Electric Power Co., Inc. (KEPCO) started the development of the Kansai Mitsubishi Carbon Dioxide Recovery KM CDR ProcessTM, a post-combustion carbon capture technology, in 1990. As of June 2020, MHI has delivered a total of 13 commercial plants with the KM CDR ProcessTM, making it a global leader in carbon capture technology deployment. Two more plants are currently under construction.

- During the pilot, MHI and Drax will test two MHI solvents: KS-1TM and KS-21TM. KS-1TM is currently being used at all commercial plants that use the KM CDR ProcessTM and has proven to be a competitive and reliable solvent of choice. MHI, with support of KEPCO, have continued to improve upon the KM CDR ProcessTM and have recently developed KS-21TM. KS-21TM has many promising characteristics including lower volatility and more stability against degradation, and MHI believes that this will result in operational cost savings making the Advanced KM CDR ProcessTM even more economic for future deployment.

- Drax announced its ambition to be carbon negative by 2030, by using BECCS at scale at its North Yorkshire power station last year.

- It is working with a number of clean tech companies which are pioneering new technologies to decarbonise other sectors and deliver clean growth for the UK.

- Drax is working with Equinor and National Grid Ventures on the Zero Carbon Humber project which aims to deliver the first zero carbon industrial cluster in the UK's most carbon intensive region using carbon capture and storage technology as well as hydrogen.

Flue gas desulphurisation unit at Drax Power Station. The massive pipes could transport over 90% of the carbon dioxide captured with BECCS and deliver negative emissions. (Graphic courtesy of Drax)

An engineer looks up at the flue gas desulphurisation unit at Drax Power Station. The massive pipe above him could transport over 90% of the carbon dioxide captured with BECCS while power is being generated. (Graphic courtesy of Drax)

The Kansai Mitsubishi Carbon Dioxide Recovery (KM CDR) Process is installed in 13 commercial plants around the world. (Graphic courtesy of MHI)

About MHI Group

Mitsubishi Heavy Industries (MHI) Group is one of the world’s leading industrial groups, spanning energy, smart infrastructure, industrial machinery, aerospace and defense. MHI Group combines cutting-edge technology with deep experience to deliver innovative, integrated solutions that help to realize a carbon neutral world, improve the quality of life and ensure a safer world. For more information, please visit www.mhi.com or follow our insights and stories on spectra.mhi.com.