MISSION NET ZERO

Accelerating R&D to achieve a carbon neutral world

AD: Produced by Toyo Keizai Brand Studio

Executive Vice President and CTO, Mitsubishi Heavy Industries, Ltd.

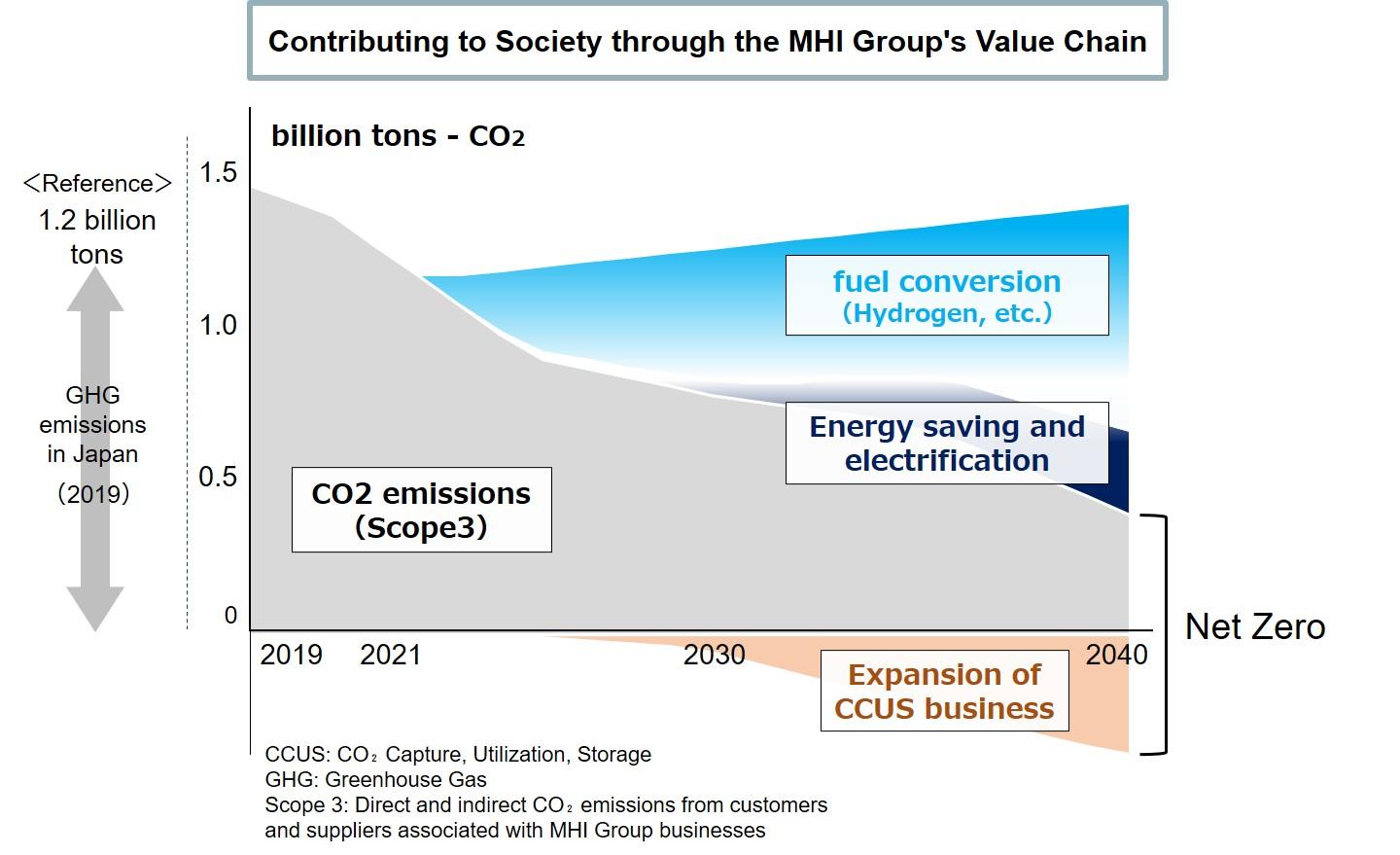

Mitsubishi Heavy Industries (MHI) Group has set itself an ambitious goal: under "MISSION NET ZERO," announced in October 2021, the company aims to achieve carbon neutrality by 2040 – fully 10 years ahead of the Japan government's own target. This drive to net zero emissions will be founded on the development of technologies such as low-carbon hydrogen and CO2 capture storage and utilization (CCUS). Their development in turn, depends on constant innovation. And that requires a research and development (R&D) system that emphasizes speed and is fit for purpose.

- Contents

- ▼Integrating MHI Group’s many knowledge silos

▼Speed is more important than building everything ourselves

▼"Pivot development" creates 24 prototypes in only one-and-a-half years

▼Reducing fossil fuels and generating 100% hydrogen-based power by 2025

▼Growing the CO2 value chain

▼Achieving a carbon neutral world and economic sustainability

Integrating MHI Group’s many knowledge silos

"MHI Group has been working to reduce CO2 emissions by providing highly efficient machinery and plants, but now we are entering a new phase – net zero CO2 emissions. We are developing solutions which will help the world achieve carbon neutrality," says Eisaku Ito, CTO of MHI.

Through Mission Net Zero, MHI aims to reduce CO2 emissions by 50% from 2014 levels by 2030 and become wholly carbon neutral by 2040, including reductions in customer emissions. The Japanese government has set a target of net zero CO2 emissions in 2050. But MHI Group is planning to be 10 years ahead of schedule and to eliminate Greenhouse Gas (GHG) emissions across its entire business value chain.

Innovation is essential to achieving this carbon neutrality and MHI Group has already established an R&D framework for new technologies, that is already producing results.

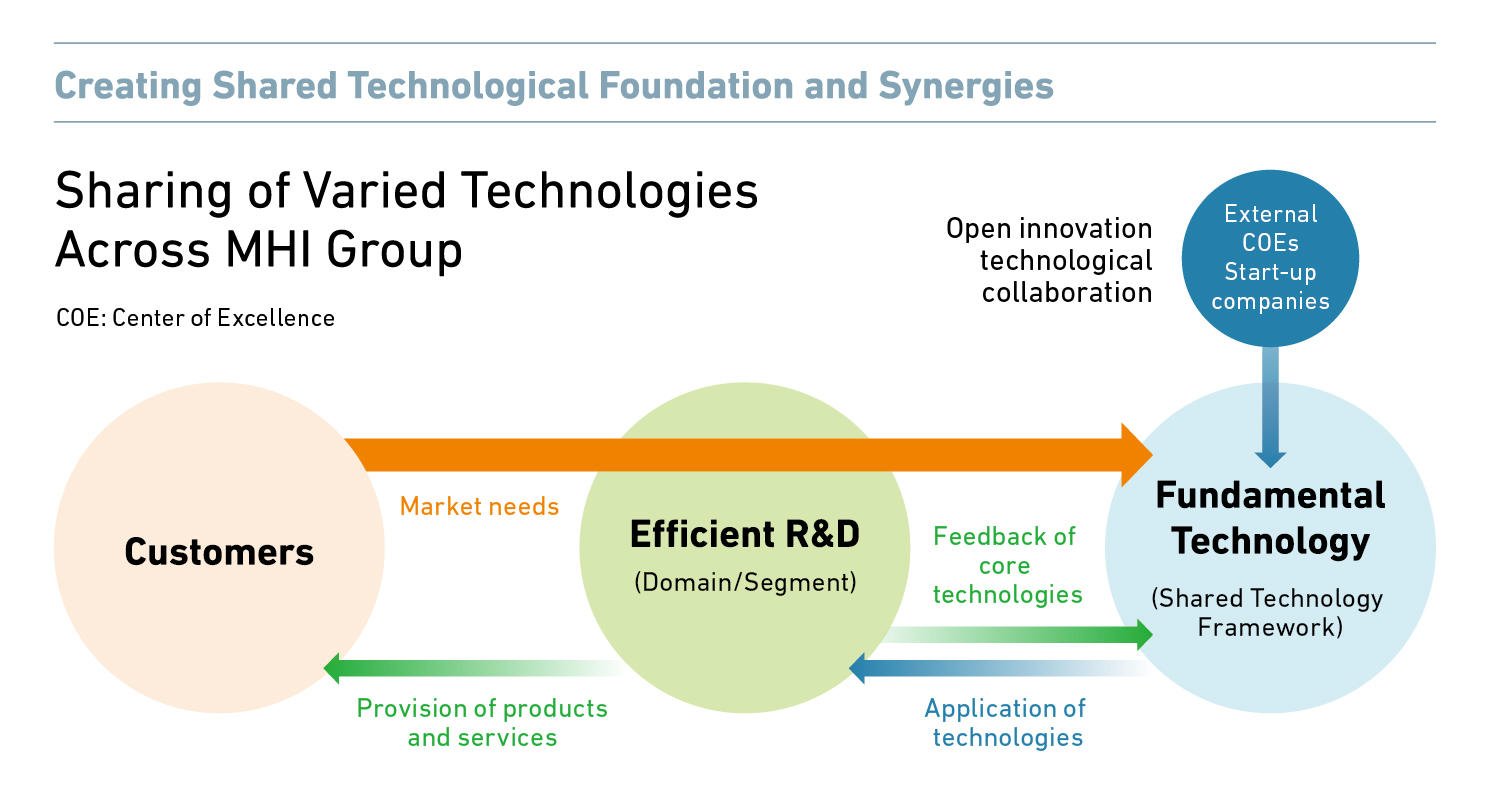

MHI Group provides a wide range of products that support society, from power generation to industrial machinery and aerospace. It established a Shared Technology department in 2016 to consolidate the knowledge that had previously been scattered through each separate business unit.

"MHI Group produces more than 500 products;” says Ito. “By combining technologies and knowledge we already have, we only need to add some "missing pieces" in order to speed up our R&D process."

The heat pump, a machine which collects heat from the air and uses it to heat a building or factory, is a good example. It was originally a product of MHI’s cooling businesses, such as the air conditioning unit. By combining this expertise with engineering technologies developed in the industrial plant businesses – for example, power generation and chemistry –we can reuse steam at greater range of temperatures and flow rate in factories.. This technology is finding wide application across industry, where it improves the efficiency of heat utilization and reduces carbon dioxide emissions.

Speed is more important than building everything ourselves

"If there is a technology that someone has already developed, it is faster to work with them. MHI has opened Yokohama Hardtech Hub (YHH), a space for open innovation, in Yokohama. YHH is currently hosting eight companies as well as MHI’s in-house venture team, which has started a demonstration project for decarbonization there,” explains Ito.

“Customers can also use YHH as a place to directly check the status of technology development and provide feedback to companies. Similar efforts are being shared with Research and Innovation Center across MHI. "

"Pivot development" creates 24 prototypes in only one-and-a-half years

The function of the Shared Technology department is not just to connect existing centers of knowledge. Under "Pivot development", it also provides a mechanism for branching out into related technologies - an unique function.

Shared Technology investigates the medium- and long-term demands of society, engages in R&D that leads to solutions to these problems and amends MHI’s technology portfolio in line with developing social trends. The company has 45 technology units such as fluid, heat transfer and combustion and, furthermore, subdivides those into 600 technology fields.

"We can conduct hypothesis tests on big issues quickly if we break the fields down to 600. The final probability of success is higher if we continually modify the project based on initial results, rather than if it is a one-shot attempt at a major challenge”, says Ito. “I call this "pivot development."

"The overall development speed naturally increases if hypothesis tests are carried out in parallel in smaller clusters, rather than working in sequence on a single big issue. Even if it fails through trial and error, it increases our knowledge. Some teams are led by young employees in their second year. I hope younger engineers will use MHI as a place to challenge themselves.", he continues.

After one-and-a-half years of trialing pivot development, MHI has tested 800 ideas, of which about half have advanced to become proper projects. Of those, 24 are already in the prototype phase - and 90% of these are related to decarbonization.

This suggests that MHI has a real chance of achieving its net zero emissions target 10 years earlier than the government. After all, it is a realistic approach backed by the new R&D system.

Reducing fossil fuels and generating 100% hydrogen-based power by 2025

So, what technologies have been developed in this R&D system at MHI?

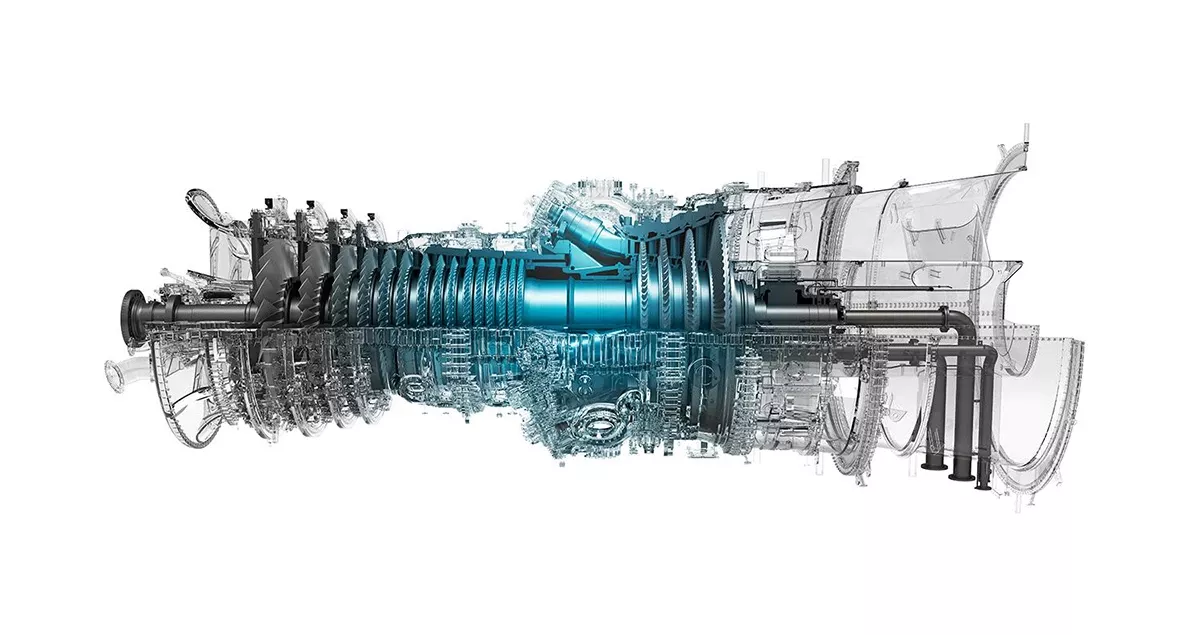

Fuels that do not emit CO2, such as hydrogen, play an important role in carbon neutrality. In fact, MHI has more than 50 years of experience in operating gas turbines fueled by BFG (Blast Furnace Gas), gas emitted as a by-product during steelmaking. This gas contains hydrogen. It means the group already has knowledge of how hydrogen behaves in gas turbines, allowing it to rapidly develop hydrogen co-firing technology.

"The goal is to increase the rate of co-firing of hydrogen to reduce the use of fossil fuels, and ultimately to achieve "hydrogen mono-firing," explains Ito. “A small 100% hydrogen-firing gas turbine has already been almost completed. Technology is also being developed for large plants that burn stably at high temperatures."

In 2018, MHI succeeded in the stable operation of a gas turbine at temperatures of over 1,600°C with a hydrogen co-firing ratio of 30%, and it is targeting 2025 to achieve 100%.

"For example, we can create hydrogen with surplus renewables by using existing power grids if we build a hydrogen production facility close to or at a power plant. If we turn this hydrogen into electricity, we can reduce social infrastructure costs such as the need to liquify, transport and store the hydrogen. Utilizing existing infrastructures with new technologies, we can provide highly economically sustainable system," argues Ito.

Growing the CO2 value chain

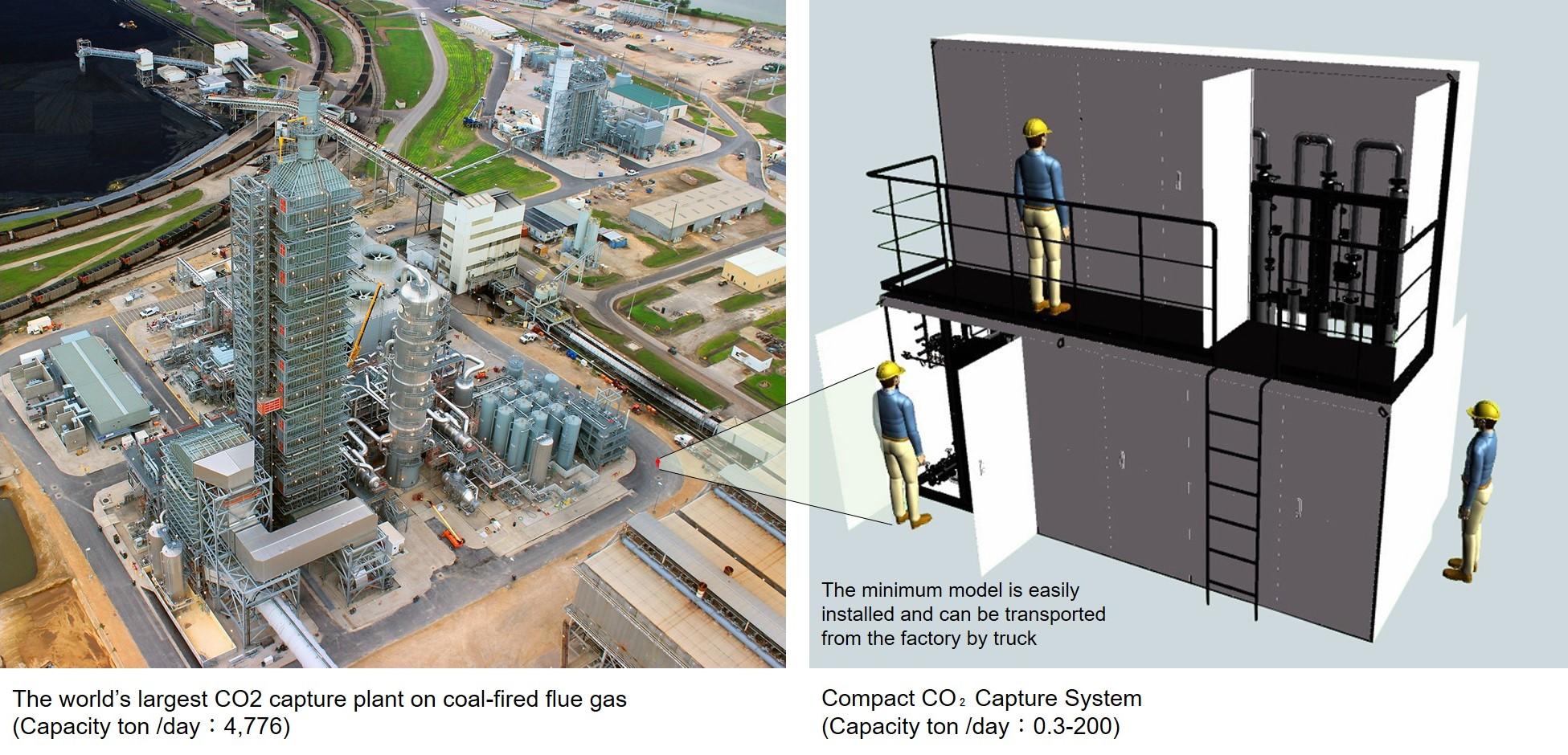

When it comes to capturing and utilizing CO2 in order to cut emissions, MHI has a big advantage: the group is the world market leader in CCUS technology with a roughly 70% share.

"In addition to the world's largest plant capable of capturing up to 5,000 tonnes of CO2 per day, we will have a new lineup of 0.3 - 200 tonnes/day by developing a compact CO2 capture system. By supporting a wide range of industries, we can scale up in the CO2 capture business field."

In general, our R&D efforts want to work with recycled materials, but the problem is that a large amount of energy is required to use them. CO2, for example, is highly stable and to turn it into something useful, you have to add the same energy as you took out. This is a potential problem, but MHI already has a solution.

"It doesn’t make sense to think only about the utilization part. It is important to consider the entire ecosystem. For example, if we have energy generated to produce somethings, then we can use some of that energy to capture or utilize the CO2 emissions, thereby optimizing overall energy consumption. MHI Group has a strong position based on more than 20 years of experience in this field."

Achieving a carbon neutral world and economic sustainability

All of these initiatives demonstrate MHI’s strong passion to realize a carbon neutral world and economic sustainability – with its technology and R&D process playing a key role.

"Customers are concerned that the cost of products may increase in the process of achieving carbon neutrality. Unless we overcome such anxiety regarding economic sustainability, we will not be able to realize a carbon neutral world," Ito cautions.

MHI is aiming to demonstrate that it can achieve both carbon neutrality and economic sustainability at its own factories. Firstly, the group calculates the minimum amount of energy required in theory for a factory’s operations, while recycling as much of it as possible. Movement of goods and equipment inside the factory is also optimized to reduce energy consumption as well as overall production costs.

"To achieve both carbon neutrality, without depending on carbon offsets, as well as reducing total manufacturing costs – that is MHI's mission”, says Ito. “Together with our customers, we will engineer a path toward a carbon neutral world."