From the site of MC development, a new corrugated board box making machine that is responsible for the production of corrugated boxes that supports our lives and economy

STORY1

The MC is a corrugated board box making machine that has evolved for the times and the needs

Online shopping and mail-order sales have become a common way of life in recent years. One thing that is essential for that distribution is corrugated board. Mitsubishi Heavy Industries Machinery Systems (MHI-MS) has been developing and manufacturing box making machines for corrugated board since 1958. In 2003, we launched the high-performance, high-efficient "EVOL." It became a global long-seller, with orders for more than 600 machines received from 32 countries worldwide, including from North America, Europe, Asia, Oceania, Africa and South America.

In 2021, the MC was developed as a new model to better suit the times and meet the needs of customers. To meet the increasingly diverse needs for corrugated board manufacturing in recent years, the MC was advanced to maintain high quality while also responding to small-lot production and realizing high efficiency.

"The requirements for corrugated board box making machines vary greatly between different countries and regions. In Japan, it is often the case that multiple different types of corrugated board are produced in small quantities. On the other hand, overseas, it may be the case that machinery is running for several hours to mass-produce just one type of product, so the needs vary greatly. This is why we started the development of the MC, with the intention of responding to the specific styles and needs of each country and maximizing the business opportunities for our customers.

Development Designing Section

Mechanical Engineering Department

Printing & Packaging Machinery Headquarters

STORY2

Realizing high productivity while maintaining the high quality of EVOL

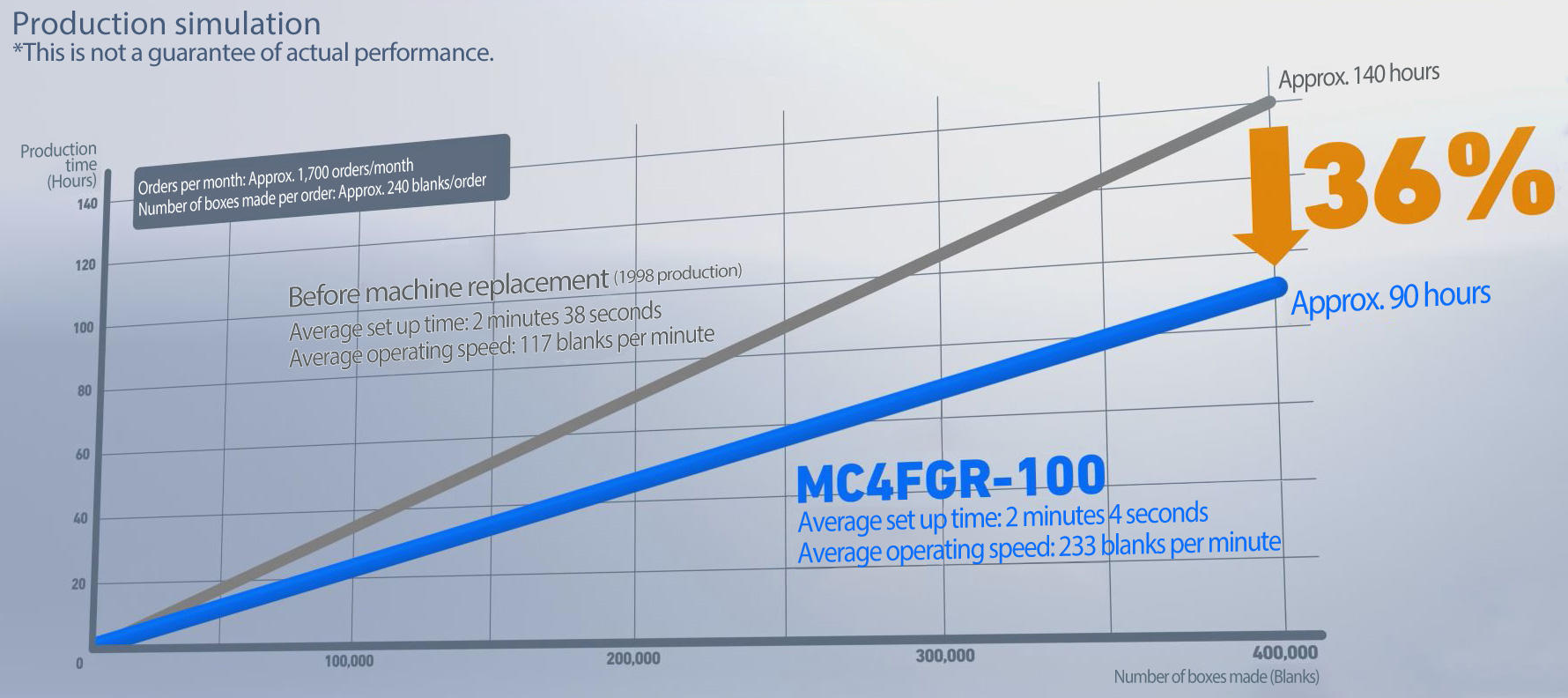

The maximum machine speed of the MC is 250 blanks per minute, which is a low machine speed compared to the EVOL. However, various improvements have been made to achieve high productivity that suits the times. For example, the total length of the machine is about two meters shorter than that of EVOL, making it suitable for compact factories. While saving space, the range of paper feeding dimensions supported has been expanded from the EVOL, for both the maximum and minimum paper feed dimensions. In particular, a big point of improvement is the reduced set up time.

| MC-100 | EVOL-100 | |

|---|---|---|

| Maximum paper feeding dimensions L × W [mm] | 1000×2555 | 950×2555 |

| Minimum paper feeding dimensions L × W [mm] | 250×630 | 250×690 |

| Maximum machine speed [blanks/min] | 250 | 350 |

| Average set up time [minutes] | 2 | 3 |

The corrugated board to be produced varies in size, thickness, design and color, depending on the application. This means that during the equipment operation, it is necessary to change the printing die every time the type changes. On the MC, in order to achieve high productivity, we succeeded in reducing the set up time for printing die by 36% compared to EVOL.

The first machine was delivered to Thailand. Further improvements were made and then, in 2021, a private viewing of the MC machine supporting production in extremely small lots was held for customers in Japan. The machine was then released.

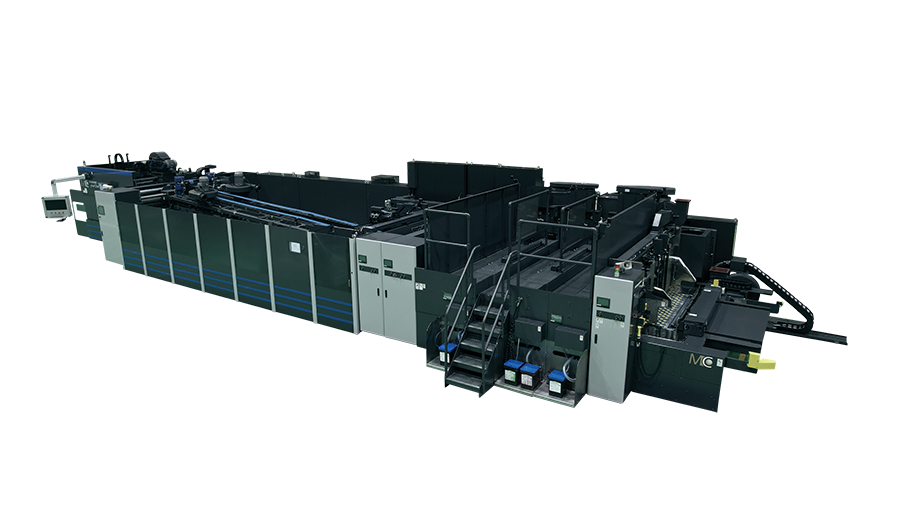

"On the MC, to improve the brand strength, we incorporated performance characteristics into the design. The blue line at the bottom of the body expresses a sense of speed. It is unusual for the body color of industrial machinery to be black. Our stylish design has been well received by our customers."

Development Designing Section

Mechanical Engineering Department

Printing & Packaging Machinery Headquarters

STORY3

What was the key to shortening the average set up time?

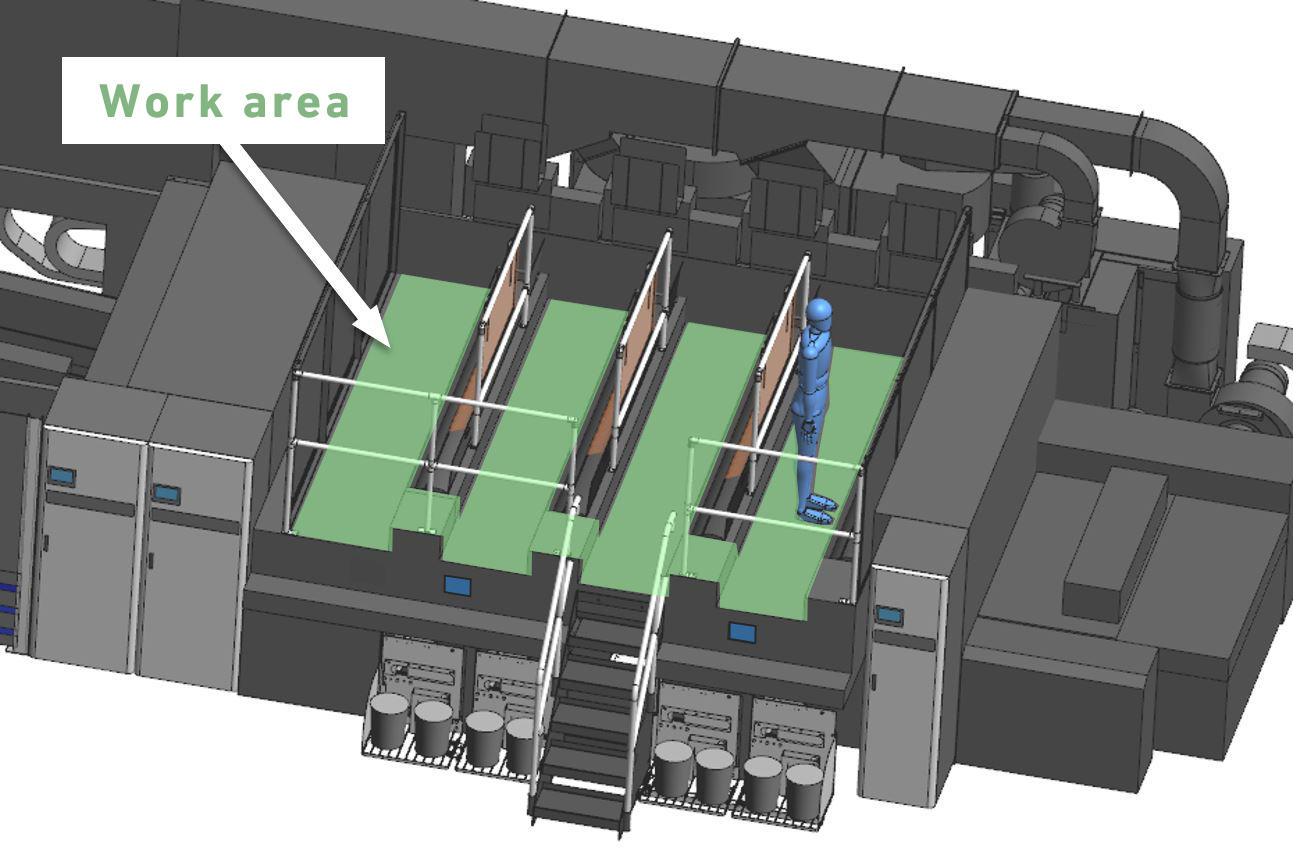

There were several elements that were key to the reduction of the set up time, which has a large effect on the realization of high productivity. We shortened the movement time when each device moves to the predetermined position for the size of box to be produced, and we also reconsidered the timing of that movement. In addition, on EVOL, when replacing the printing die, it is necessary to go up and down the footsteps each time. On the MC, improvement to the printing unit eliminated the need for the footsteps and created a flat work area. This has reduced the burden on the operators in the workplace.

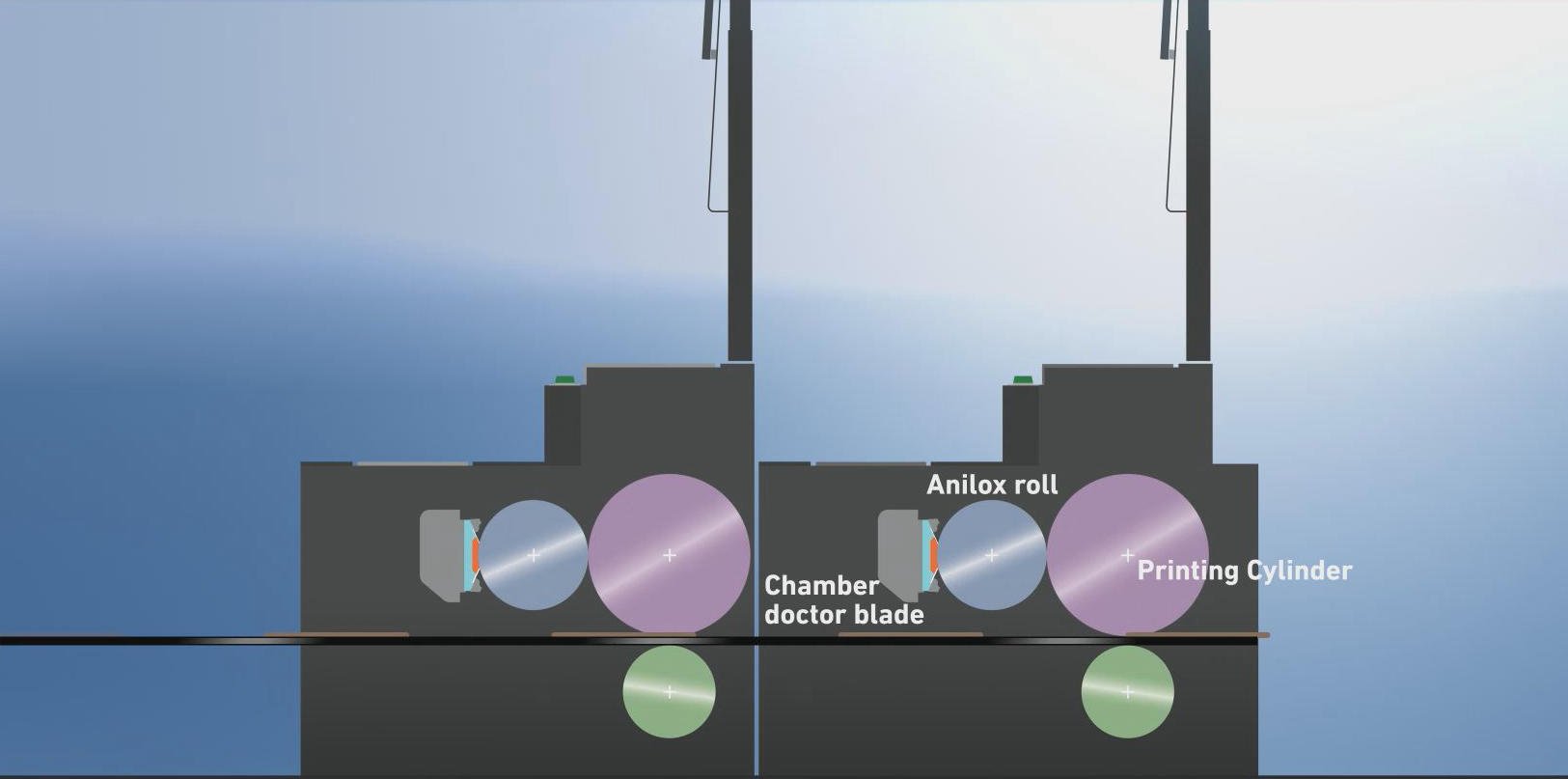

A. K. explains that, "Several metal rolls are on the ground in the flexographic printing mechanism that prints the corrugated board. To create a flat work area above the printing unit, we improved the position of the anilox roll, which is responsible for putting the ink on the printing plate. Items that were arranged vertically on the EVOL have been changed to a horizontal layout to save space. During the development, we consulted with our seniors who were the developers of EVOL about how much improvement we could make without a loss of the basic performance. We strived to maintain the high performance produced so far while also achieving high efficiency."

Development efforts such as these also contribute to carbon neutrality. Starting from the shortening of the set up time, the reduction of the total length of the printing unit meant that the motor capacity was reduced. As a result, the electricity consumption was reduced by 7% compared to EVOL, which lead to a 50 ton per year reduction of CO2 emissions.

STORY4

The MC development was achieved thanks to our strong team

Prior to the development of the MC, both A. K. and T. E. worked on newspaper offset presses. A. K. explains that, "In our company, we develop plant in addition to paper machinery. In the development in this field, the actual drawings you draw take shape in front of your eyes and the customer uses them to carry out production activities. As we can then also watch over the improvement work that follows, I feel that this makes the work more worthwhile."

The MC development team is about 10 personnel in total. The core members are in their thirties. The entire box making machine is roughly divided into seven units, so one or two personnel are responsible for designing one unit. After the project office was established, each person performed the design in the same room. It was an environment that enabled frequent communication.

T. E. explains that, "We held a development meeting every morning to check the progress and to check the tasks for that day. Other than when we went out to the demonstration site, all the members were working on the design in the same room, so it was easy to consult with others if we had trouble with the development. When we are working alone, our thoughts tend to go around in circles, but it was a very good environment because we could have discussions without barriers created by hierarchical relationships."

STORY5

Aiming for standardization and common use for box making machines as they spread around the world

We asked how such large box making machines are delivered to the customer's location. They explained that the machine is first assembled at the factory for operation testing, and then, after passing the tests, it is divided into units and transported on trucks. When shipping overseas, the units are transported on a container ship. It is confirmed at the customer site that the performance is equivalent to that in the factory and then the machine is delivered to the customer.

Currently, orders for the MC have literally been received from around the world, from Japan and also from Thailand, Switzerland, Turkey and the United States. For the Turkey and United States orders, the manufacturing is currently being performed in preparation for the delivery. They say that the nature of the country also affects what is developed.

"We are currently in the process of developing new equipment to meet the demands of the customers. Going forward, we will promote the standardization and common use of the products based on the knowledge we gain through the development tailored to each country and customer. This is because it will be essential to achieve more stable production if we are to continue production and sales for several decades to come."

It is no exaggeration to say that corrugated board is an essential part of our lives. The tireless efforts of developers have been behind the manufacturing of that corrugated board. In addition, in these times of rapid change, it is essential to have development that catches and responds to the current trends. It is very exciting to think about how high-performance corrugated board box making machines have spread out from Japan to the rest of the world. MHI-MS will continue to take on such challenges.

PRODUCTS COVERED

Development Story

R&D

- Research System and Development Base

-

Strategic Innovation

- The world’s first! A Next-Generation ERP to Realize the Roads of Tomorrow in Singapore

- Meeting the needs of global logistics! The EVOL box making machine enables the high-speed mass production of corrugated board boxes.

- Keep a drink delicious and fresh! A carbon coating that evolves PET bottled beverages.

-

From the research and development sites

-

Development Story

- Next-Generation Multistory Parking Lot installed underground in the inner-city - Birth of the Mitsubishi Cell Park (Two-Lift Type) -

- From the site of MC development, a new corrugated board box making machine that is responsible for the production of corrugated boxes that supports our lives and economy

- Closing in on the latest research on a tire inspection machine that underpins the growth of a motorized society.

-

Innovators

- A magnitude 7 earthquake is faithfully reproduced in every detail! “Advanced hydraulic and control technologies” to shake full-scale medium-rise buildings.

- Rapid, beautiful, economical! A newspaper offset press developed to lead the world.

- Generate novel experiences in large-scale facilities that inspire and amaze people and awaken them to new possibilities. Frontline “Moving Technology.”

-

Development Story

- Mitsubishi Heavy Industries Technical Review