A magnitude 7 earthquake is faithfully reproduced in every detail!

“Advanced hydraulic and control technologies” to shake full-scale medium-rise buildings.

E-Defense was developed in response to the unparalleled damage caused by the Great Hanshin-Awaji Earthquake.

Japan is the most earthquake-prone country in the world. To better protect its citizens, Japan rolls out a renewed set of quake-resistance standards for buildings after every big earthquake strikes. Disaster prevention awareness has significantly risen throughout the country in recent decades. The awesome damage caused by the Great Hanshin-Awaji Earthquake (Hyogo-ken Nanbu Earthquake) of 1995 put the public on high alert.

The 7.3 magnitude quake hammered much of the Kansai area, wreaking tremendous damage in buildings, condominiums, detached housing, bridge columns, and other structures.

The World's Largest Facility. The shaking intensity is strong enough to collapse buildings.

Lessons learned from past earthquakes are used to review the quake resistance and evaluation methods applied for buildings. A national project was launched to study building designs that protect human lives from earthquakes.

To succeed, the project required an experimental facility capable of testing how actual-size bridge beams and buildings fracture during an earthquake, as well as the extent of the fracturing and why the fracturing occurs.

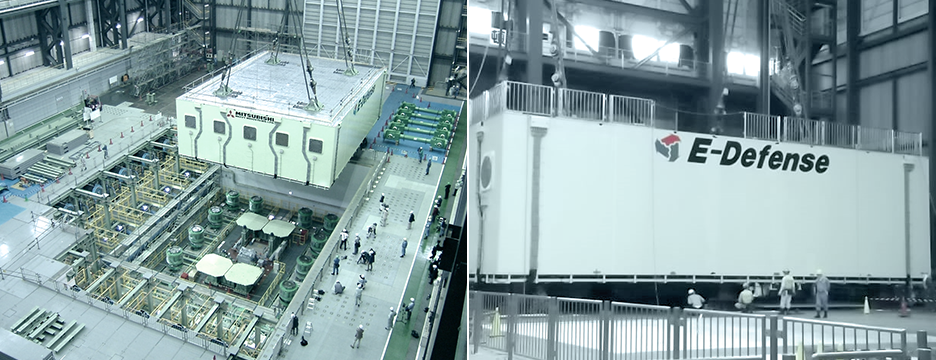

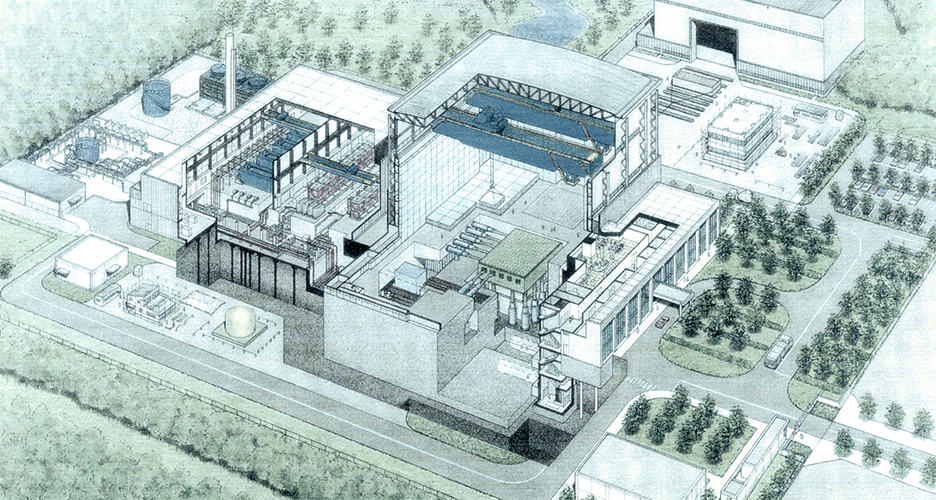

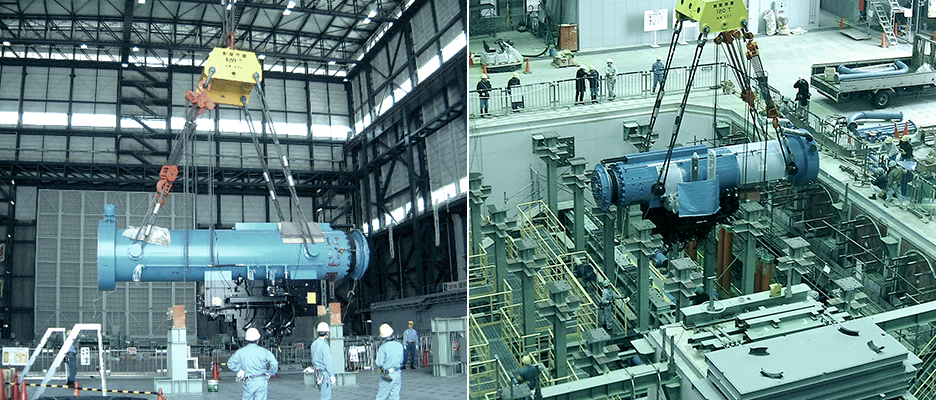

E-Defense, the full-scale, three-dimensional earthquake testing facility was developed and manufactured by Mitsubishi Heavy Industries Machinery Systems (MHI-MS) as the core research facility for the project.

The facility took ten years to develop and build. It finally became operational in Miki City, Hyogo Prefecture, in 2005.

The actual size, three-dimension, and fracture concepts

Movie of an experiment performed with an actual-size building loaded on E-Defense.

E-Defense is the only facility capable of imposing a simulated earthquake with the same force as the Great Hanshin-Awaji Earthquake on an actual-size structure mounted on a shaking table, and validating the effects by characterizing the fracturing of the structure in great detail.

The shaking table measures 20 meters × 15 meters and supports a maximum loading weight of 1,200 tons. No other shaking table matches it in size or weight-bearing capacity.

The shaking experiments conducted so far have been performed by national and private research organizations and enterprises to clarify fracturing mechanisms and validate aseismic reinforcements.

The various kinds of knowledge learned have contributed to diverse earthquake countermeasures focused on quake-resistant engineering for buildings, safety measure in living spaces, monitoring technologies to evaluate aseismic performance, etc. The research results attract worldwide attention.

E-Defense continues to evolve and gain new capabilities to respond to the latest research themes.

E-Defense can simulate earthquakes for structures weighing of up to 1,200 tons, or the equivalent of a 6-story building.

Is it actually possible to develop a model driven by electrical power on this scale? The only hydraulic power can generate big force instantly and precisely.

A.S joined the company in 2003, just when the final tests were being performed on the E-Defense facility.

“E-Defense is the world's largest test facility of its type, both in size and power. I will never forget the surprise I felt when I first saw this massive machine.”

The amazement felt by her, an engineer in charge of electrical control design, was understandable. Large shaking tables of course existed, but none were of a scale massive enough to mount an actual-size building.

The people in charge of development at the time reviewed various kinds of structures to cross the scale hurdles.

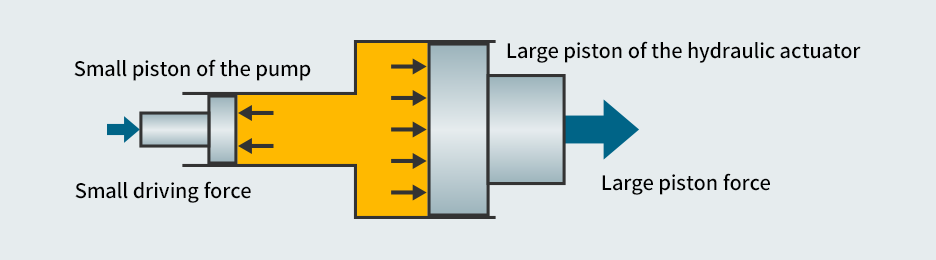

Ultimately they adopted a “hydraulic pressure (note)” system for power transmission.

- “Hydraulic pressure” transmits force or energy using the pressure of oil. A hydraulic pump generates pressure by pushing pistons with a small amount of pressurized fluid. Less pressure pushes a smaller piston; more, a bigger piston. E-defense generates a huge force with massive pistons built into the shaking mechanism . The pressure is used to drive various devices and machines such as press machines, crane cars, and so on.

Test Equipment Team, Hydraulic Control Design Section Electricity & Control Systems Engineering Department,

Infrastructure Facilities Business Division

The mechanism of hydraulic pressure

While hydraulic pressure can generate big force, no other facilities in the world were powerful enough to shake full-scale buildings (equivalent to a medium-rise building or two detached houses ).

The engineer in charge of the machine and hydraulic system designs, explains: “A hydraulic actuator of a conventional size, with the valves and pipes to scale, was assumed from the beginning to be inadequate for the task. The system we designed had to be extraordinarily big. We also knew that the actuation of the hydraulic mechanism would be much slower than the rapid actuation of an electrical system. We therefore had to establish a precise control technology in order to reproduce the earthquake motion with high precision.”

The hydraulic system ultimately developed optimizes the advantages of a hydraulic mechanism while compensating for its weaknesses.

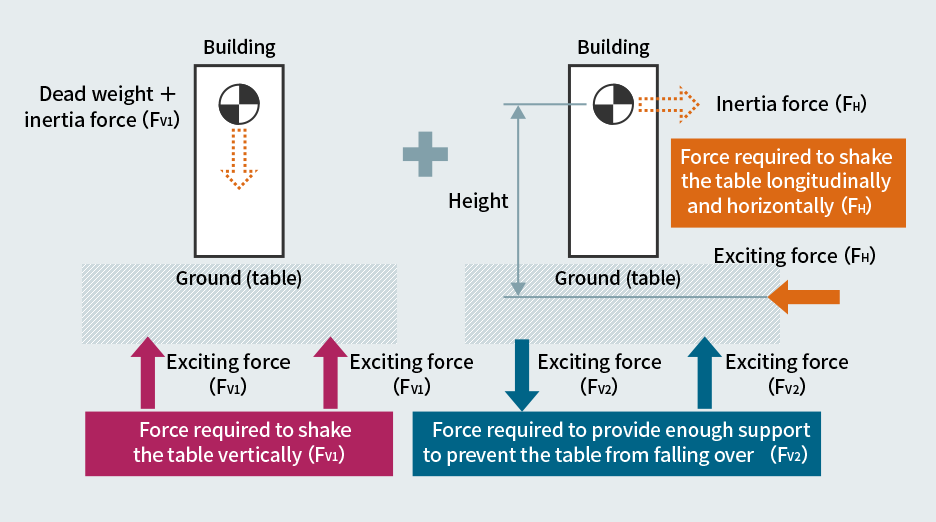

E-Defense was required to exactly reproduce the shaking of an actual-size mid-rise building by a magnitude 7 earthquake.

The shaking motion of the table has to match the ground motions longitudinally, horizontally and vertically, but the table itself cannot be allowed to fall over.

Force necessary to shake a table

The hydraulic actuator must have sufficient force to shake the combined mass of the building and table longitudinally, horizontally, and vertically.

The vertical actuator must also provide sufficient support force to prevent the table from falling over while supporting the weights of the building and table. The Force required to prevent rotation and support the building and table, FV2, is determined by the equation “force (FH) × height.” The taller the building to be shaken is, the greater the required vertical actuator force becomes.

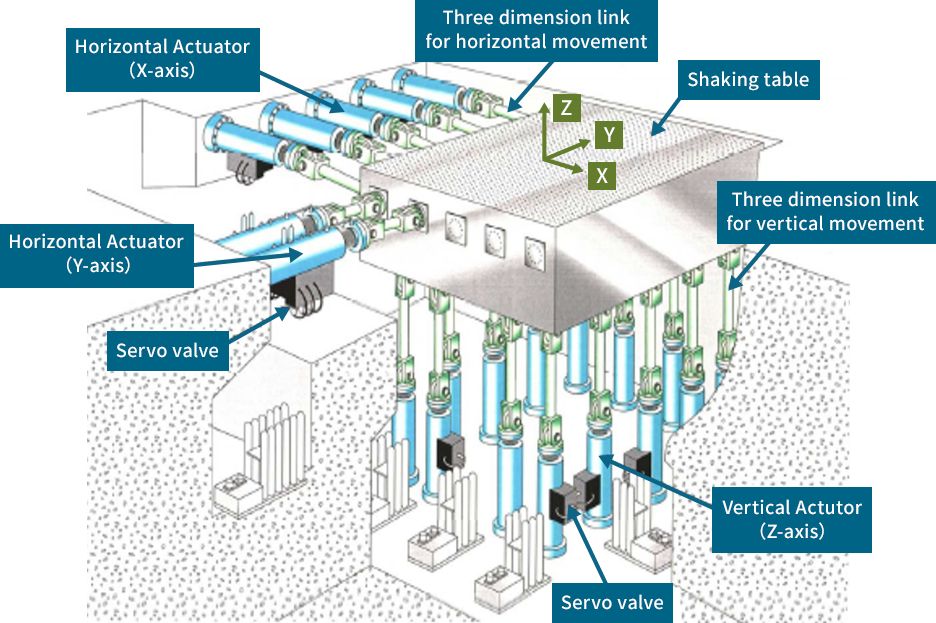

Accordingly, 24 actuators are provided to hydraulically drive the movement of the table in 3 dimensions with 6 degrees of freedom. The system can be aptly described as a super-redundant drive. The 24 actuators can be controlled cooperatively by calculating the three-dimensional attitude (position and angle) of the table from the strokes of the actuators. Thus, the 24 actuators rationally share the load from the table.

The blue columns are the actuators composing E-Defense: 5 longitudinal, 5 horizontal, and 14 vertical actuators reproduce a three-dimensional quake.

A slower earthquake is fairly easy to reproduce. Earthquakes overall, however, strike in various patterns. The Great Hanshin-Awaji Earthquake was an “epi-central earthquake” that shook buildings intensively like sudden vertical bumping from beneath. To reproduce a quake of that type, the tardy response of the hydraulic system must be corrected.

A.S explains the mechanism to correct the tardy response of the hydraulic system: “The tardy response poses no problem if the movements of a quake can be well reproduced. All we have to do is to factor in a delay in the timing of the output of the excitation signal.”

Earthquake motion is a superposition of rapid and slow waves taking place over various periods. The delay and amplitude of the hydraulic system both differ among the periods. No excitation signal is output in a prescribed period of time in advance. The signal, which elicits a requested response, is generated by sufficiently grasping the delay in each period of the hydraulic system and the corresponding amplitude characteristic.

The reproducibility, meanwhile, was realized with a precise processing technology for “super-jumbo” parts used in the actuators and special mechanisms such as hydrostatic bearings, etc. A hydraulic system capable of generating a big force both instantly and precisely was thus constructed.

Respond to the long large-scale shaking observed in the March 2011 Earthquake

Every time a new earthquake occurs, the types of earthquakes to be reproduced increase.

While E-Defense started operation smoothly, further development was required after the Great East Japan Earthquake struck off the Pacific Coast of Tohoku in 2011.

Long-period ground motions caused a resonance phenomenon affecting large structures. The “period” of an earthquake means the time taken to complete one cycle of motion. Some periods are as brief as 0.05 seconds, while others can continue for as long as 2 to 5 seconds. The slower motions are called long-period ground motions.

A long-period ground motion is apt to affect high buildings. The March 2011 earthquake caused many problems in inner-city office buildings such as over-turned servers and emergency elevator shutdowns.

“To get E-Defense to shake for the long period required, a huge amount of oil would have to be poured into the actuators continuously the whole time. The first option we considered to permit this, a further enlargement of the hydraulic supply system, was judged to be difficult in view of the cost and site area. Next we determined that oil could be saved by closing some of the valves to cease operation of the actuators that were not required to deliver force. This option also proved unfeasible, however, as any non-operable pistons would stop the movement of the table. The breakthrough solution we ultimately came up with was to circulate the oil inside instead of pouring it into the actuators.” This circulation could be achieved by creating a bypass, that is, a passage through which the oil could flow.

In practice, this required only a minimum of modifications. Hence, E-Defense became newly capable of reproducing earthquakes of all durations, from short periods to long periods.

Custom-made test equipment actively used in various fields

Beyond the test equipment to reproduce the earthquake phenomena, MHI-MS has developed an array of custom-made test systems to reproduce the phenomena of automobile collisions and vibrations in traveling automobiles and railway trucks; to meet the needs of automobile and parts manufacturers and research institutions in various fields; to test the properties of seismic isolation rubber for buildings and bridges; and so on.

Incorporating ideas of hydraulic × control systems becomes a key for technical innovation.

Mechanical design of the hydraulic system, and design of the control system to precisely control it.

MHI-MS has developed an epoch-making product by bringing together a team of engineers from different fields to exchange ideas and shore them up.

“When I'm stuck on a problem,” the engineer says, “I often talk with the members of the Control Design department. I can sometimes find answer through their viewpoints. Of course the reverse also takes place. Our approach is to overcome problems by cooperating together.”

A.S also says that the team is closely united. “We take part in every stage of a project, from the initial inquiry to the design, installation work, and after-sales service. We often come up with new ideas or innovations not only in the office, but from discussions with customers and business partners at sites or business trip destinations.”

Peers with high technologies come together and accumulate technologies that transcend the boundaries of their respective departments. This company culture has brought us global success in launching first-ever and bigger-than-ever projects.

Innovation to protect safety and security with homegrown technologies from Japan.

The development of large-scale test systems like E-Defense has high social value linked directly to secure and safe lives.

Large-scale earthquake disasters have recently been striking not only in Japan, but all over the world. Overseas research institutes now have more opportunities to participate in experiments using E-Defense.

Research and development relating to enhanced quake resistance in buildings will be more important in the future. The probability that a large-scale Nankai Trough Earthquake, Metropolitan Vertical Earthquake, etc. will strike in the next 30 years is approximately 70%. To prepare, development and demonstration experiments will be imperative to devise new methods to reinforce and construct buildings.

MHI-MS as a test equipment manufacturer in Japan, a nation of frequent earthquake, should meet the requirements of innovative earthquake simulation in the future.

To protect people's lives and properties and contribute to the world's disaster prevention countermeasures--. MHI-MS is taking on this mission now and will boldly grow the mission going forward.

Introducing the engineers

A.S

Test Equipment Team, Hydraulic Control Design Section, Electricity & Control Systems Engineering Department

Joined the company in 2003.

Favorite book:

“How Do You Live?”

What she learned from her favorite book:

The living style of walking under the sun with a head held high and steadfast smile

PRODUCTS COVERED

Innovators

R&D

- Research System and Development Base

-

Strategic Innovation

- The world’s first! A Next-Generation ERP to Realize the Roads of Tomorrow in Singapore

- Meeting the needs of global logistics! The EVOL box making machine enables the high-speed mass production of corrugated board boxes.

- Keep a drink delicious and fresh! A carbon coating that evolves PET bottled beverages.

-

From the research and development sites

-

Development Story

- Next-Generation Multistory Parking Lot installed underground in the inner-city - Birth of the Mitsubishi Cell Park (Two-Lift Type) -

- From the site of MC development, a new corrugated board box making machine that is responsible for the production of corrugated boxes that supports our lives and economy

- Closing in on the latest research on a tire inspection machine that underpins the growth of a motorized society.

-

Innovators

- A magnitude 7 earthquake is faithfully reproduced in every detail! “Advanced hydraulic and control technologies” to shake full-scale medium-rise buildings.

- Rapid, beautiful, economical! A newspaper offset press developed to lead the world.

- Generate novel experiences in large-scale facilities that inspire and amaze people and awaken them to new possibilities. Frontline “Moving Technology.”

-

Development Story

- Mitsubishi Heavy Industries Technical Review