News

Mitsubishi Heavy Industries Compressor Corporation Delivers World’s Largest CO2 Geared Compressor in Landmark Post-Combustion Carbon Capture Facility

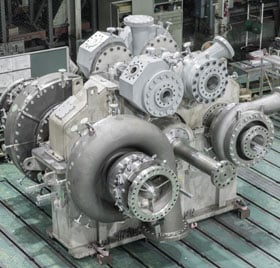

Mitsubishi Heavy Industries Compressor International Corporation (MCO-I), a joint venture between Mitsubishi Heavy Industries Compressor Corporation (MCO) and Mitsubishi Corporation (MC), recently delivered the world’s largest integrally geared CO2 compressor (IGC) to the Petra Nova Carbon Capture Project. At 1,885 psi (130 bar), the high pressure IGC is utilized in enhanced oil recovery (EOR) operations to boost production at the West Ranch Oilfield, operated by Hilcorp Energy Company. CO2 is compressed and transported through an 81 mile pipeline at a pressure where it can be used without further compression.

Technology provider Mitsubishi Heavy Industries America, together with TIC Construction, a division of Kiewit, provided design, procurement and construction for the carbon capture facility. MCO-I was selected to supply the highly efficient integrally geared CO2 compressor package that included a 21 MW motor, instrumentation and spare parts. The eight-stage IGC’s high efficiency derives from state-of-the-art impellers, multiple movable inlet guide vanes and inter-stage coolers.

From the initial stages of the project, MCO-I implemented dynamic simulation of the plant to optimize compressor performance and shop tested the equipment under full-load and full-pressure conditions, utilizing CO2 gases.

“Innovation in our IGC product line and advancements in the development of next generation technology for EOR helped make this project successful,” stated Simon Lott, Executive Vice President, Sales, Marketing, & Commercial of MCO-I. “By utilizing IGC technology and modularization practices in place of a standard in-line compressor, we offered a more sophisticated and cost effective solution within a smaller footprint. Our double flow IGC main air compressor, in the air separation business, also underlines our innovative growth in the IGC market.”

The IGC was designed, manufactured, and performance tested by MCO in Hiroshima, Japan. Installation was facilitated through MCO-I’s Houston area based sales and service center, Pearland Works. “MCO-I supports safe installation and high operational reliability out of the most modern facility in the Gulf Coast,” said Masanori Kobayashi, President of MCO-I. “With Pearland Work’s advanced tooling and highly skilled staff we are able to support our customers throughout the lifecycle of their equipment.”

Petra Nova Carbon Capture Project

The CO2 capture and compression system at the W.A. Parish coal-fired generating station is part of the Petra Nova Carbon Capture Project which is jointly promoted owned by NRG and JX Nippon Oil & Gas Exploration Corporation (JX Nippon). The project went online at the end of 2016 and is delivering captured CO2 through an 81-mile pipeline which is used for enhanced oil recovery at the West Ranch Oilfield, located on the Gulf Coast of Texas.

About MCO-I

Mitsubishi Heavy Industries Compressor International was established in the United States in October 2012 as a group company of Mitsubishi Heavy Industries, Ltd. (MHI). Mitsubishi Heavy Industries Compressor Corporation (MCO), a wholly-owned subsidiary of MHI in Hiroshima, Japan, holds a 70% stake with Mitsubishi Corporation (Americas) as a 30% joint venture partner. MCO-I provides new unit sales and customer service support out of their Pearland TX based headquarters, Pearland Works. Pearland Works is a state-of-the art sales, packaging, service, repair and storage facility backed by local sales, engineering, and operations experts.