Gas Processing

The natural gas which is produced underground contains carbon dioxide, hydrogen sulfide, and other impurities, as well as other substances such as sand. The gas is processed at a gas processing plant constructed at the wellhead in order to create clean gas, and is then either sent via pipeline or else liquefied at a LNG plant and transported to the locations of consumption.

The methods of processing natural gas include first using a separator to separate out water and sand, then using chemical solutions and other means to remove harmful components with CO2 gas and hydrogen sulfide removal equipment. Finally a refrigeration system removes the slight amounts of water vapor and oil contained in the gas, yielding natural gas in its product form.

Compressors delivered by MCO play key roles in this gas processing.

Gas processing compressors

Gas gathering compressors

MCO has applied the range of anti-corrosion technologies which we have developed over many years to offer compressors which provide stable long-term operation.

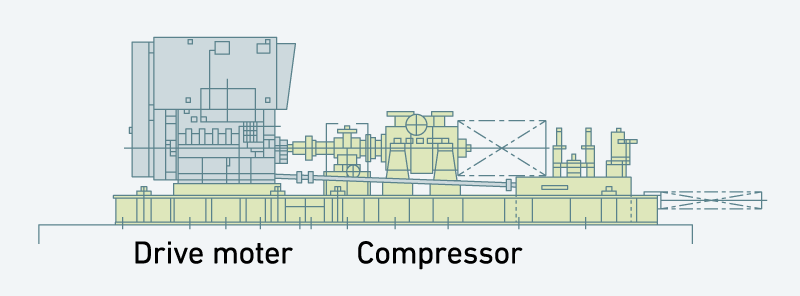

The photo at rightbelow shows a compressor (model 4V-9B) and drive motor which are used for gas gathering at a gas processing plant in Brazil.

This compact system includes equipment which supplies lubrication oil to the bearing that supports the rotor in the compressor train. This equipment is integrated with the common base plate that bears the compressor unit and the drive unit. This type of system is characterized by short and easy installation work at site.

Sales gas compressor

This requires transporting large volumes of gas to distant locations, and high pressures may be involved. For this reason, special technologies are used to stabilize shaft vibration.

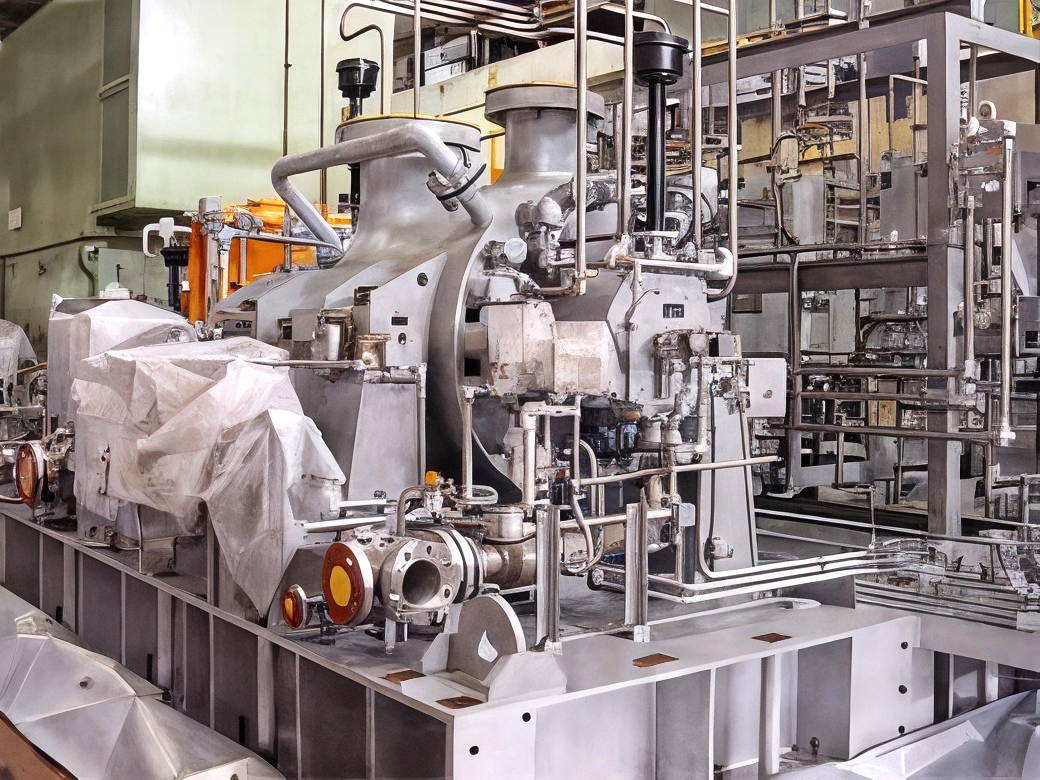

The photo at rightbelow shows compressors (model 4V-4) and drive motors which are used to transport gas at a gas processing plant in Saudi Arabia.

A total of four compressors are installed. At the time of installation, these compressors supplied approximately half of the natural gas which was used in Saudi Arabia.

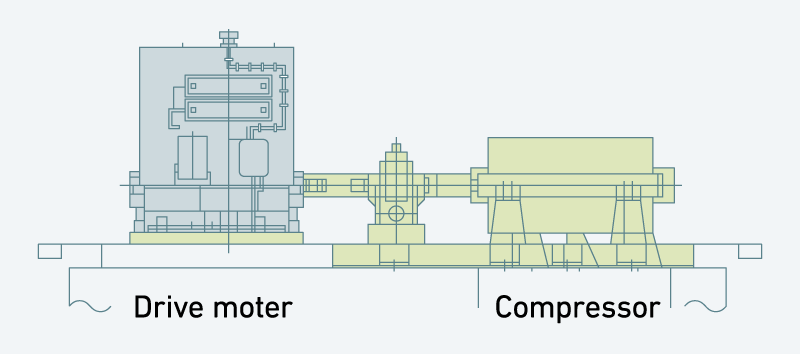

Propane (C3) refrigeration compressor

This compressor is large for a refrigerant compressor. MCO applied the refrigerant compressor technology which we have developed over many years to achieve a gas mixing and compressing process inside the compressor that utilizes cutting-edge design and manufacturing technologies.

The drive unit contains a motor and inverter which allow variable-speed operation, and includes design technologies which are capable of handling the various torque ripples (fluctuations) generated by the inverter.

Business

-

What our products and service?

- Offshore Oil & Gas Production

- Gas Processing

- Gas Injection / EOR (Enhanced Oil Recoverly) / Carbon Dioxide Capture and Storage (CCS)

- LNG / Floating LNG

- Refinery

- FPSO: Floating Production, Storage and Offloading System

- Gas to Liquid (GTL)

- Pipeline / Gas storage

- Ethylene / PDH Plant

- Fertilizer Plant

- Methanol Plant

- Nitric Acid Plant

- PTA Plant

- Power Plant

- Air Separation Unit

- Power Generating Facility

- Delivery record

- Facility

- Improvement & Revamp

- TRAINING

- Energy Transition