Pipeline / Gas storage

Pipeline compressors are installed for the purpose of efficiently pumping natural gas from the wellhead to a power plant or to the location of consumption area in a major city.

At a pipeline of approximately 3,000 km delivered by our company in South America, 10 – 20 unmanned compressor stations are installed every 200 km. The compressors used for this purpose must be highly reliable with no malfunctions, and provide a broad operating range that can flexibly adapt to changes that occur with different seasons and different times of day.

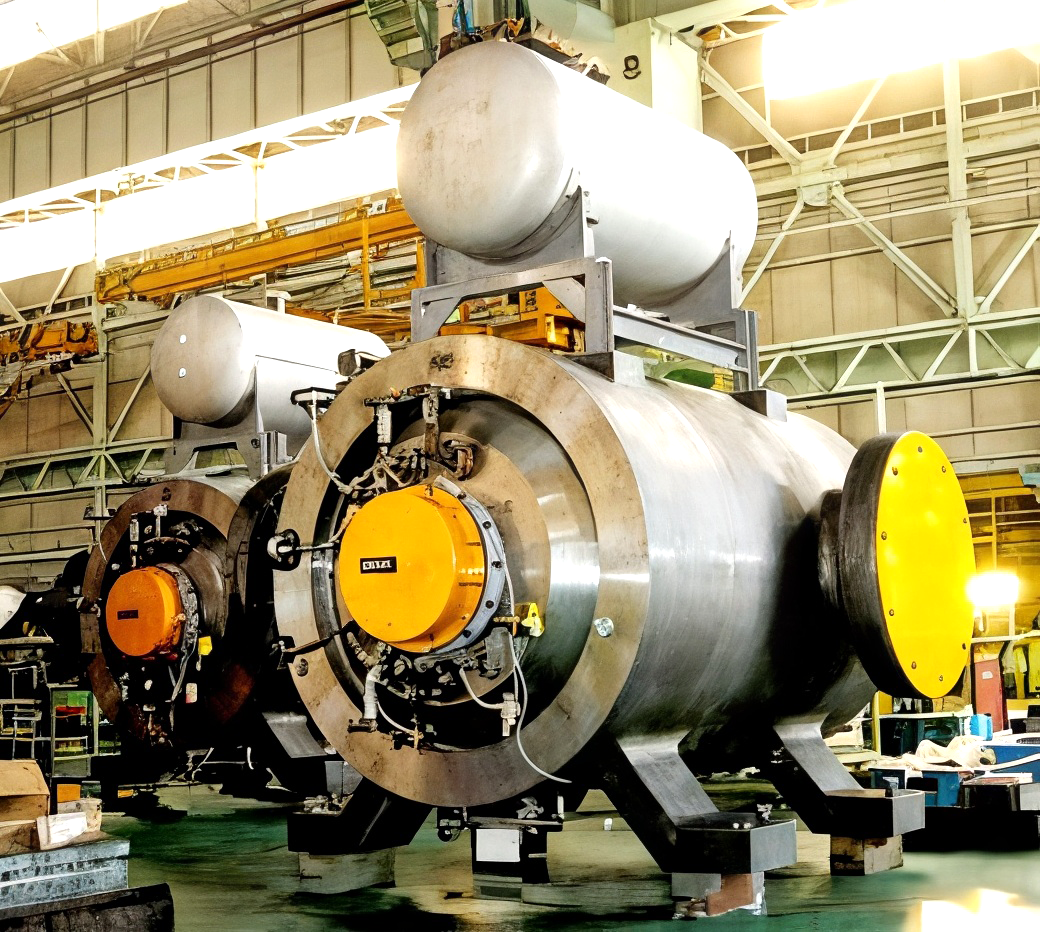

Gas pipeline compressor

Features

- High-efficiency, three-dimensional impeller: Boosts efficiency and reduces CO2 emissions.

- Dry gas seal: Improves maintainability.

- Swirl canceller and overhang damper: Improve stability during long-term continuous operation.

Pipeline compressors and gas turbines driver

As shown in Table 1, a series of MCO compressors are available for use with 4 – 25 MW gas turbines drivers.

| Compressor model | 3V | 4V | 5V | 7V | |

|---|---|---|---|---|---|

| Operation | Maximum speed(rpm) | 14000 | 10000 | 9000 | 7100 |

| Compatible gas turbine force(MW) | 4.0 | 6.3/10 | 12 | 16/25 | |

Business

-

What our products and service?

- Offshore Oil & Gas Production

- Gas Processing

- Gas Injection / EOR (Enhanced Oil Recoverly) / Carbon Dioxide Capture and Storage (CCS)

- LNG / Floating LNG

- Refinery

- FPSO: Floating Production, Storage and Offloading System

- Gas to Liquid (GTL)

- Pipeline / Gas storage

- Ethylene / PDH Plant

- Fertilizer Plant

- Methanol Plant

- Nitric Acid Plant

- PTA Plant

- Power Plant

- Air Separation Unit

- Power Generating Facility

- Delivery record

- Facility

- Improvement & Revamp

- TRAINING

- Energy Transition