Corrugating Machines

Realizing high quality and stable productivity required in the world.

Contributing to stabilizing quality of corrugated boards and increasing revenue.

Corrugated board is an essential part of our everyday life, providing an effective and renewable source of packaging and shipping material for virtually any and all products.

Mitsubishi offers high-speed "STEADY STATER" concept corrugating machines, SH-400 series that boasts a maximum production speed of 400 meters per minute, as well as diverse lineups, including H series corrugating machines, which can realize optimum productions based on customers' needs. We will propose the best suitable machine according to customers' requirements such as labor saving, less maintenance, and environmental friendliness.

SH-400 (Double Cut-off type)

H-350 (Single Cut-off type)

SH-400 (Double Cut-off type)

General Specifications

| Model | SH-400 | H-350 |

|---|---|---|

| Maximum speed (Wet-end) | 450m per minute | 380m per minute |

| Maximum speed (Dry-end) | 400m per minute | 350m per minute |

| Maximum paper width | 2,800mm (110.24"), 2,500mm (98.43") | 2,800mm (110.24"), 2,500mm (98.43"), 2,200mm (86.61") |

| Paper roll diameter | 450mm (17.72") - 1,524mm (60.00") | |

| Overall length of machinery | approx.130m (426.51') | approx.115m (377.30') |

| Cut-off classification | Double | Single |

| Manufacturable corrugated board | Single wall / Double wall | |

| Manufacturable flute | A · B · C · E · F · AB · CB · CE · BE · AA, etc. | |

| Manufacturable paper weight | [Liner] 90g/m² - 440g/m² [Medium] 90g/m² - 280g/m² |

|

Single Facer

60N

60N Single Facer applies the Belt Press System, which Mitsubishi has more than 30 years of experience with. This system eliminates pressure-marks on corrugated boards. Full and Semi automatic cartridge changes are available to adapt as an option. Single cartridge type with forklift is also available. Peripherally heated corrugating rolls are equipped as standard.

60H

Better corrugating starts with superior technology. Mitsubishi’s 60H Single Facer’s patented Kappa Belt pressure system applies even, optimum pressure to the corrugating roll, effectively eliminating pressure marks and board defects common among pressure roll designs.

Preheater

61N/62N

Wrap roll remote adjustment device and process control function are equipped as standard, the amount of preheating can be optimally controlled. Contributes to labor savings and improved corrugated board quality.

Mill Roll Stand

63N

63N Mill Roll Stand reduces operator work and makes it easier to change paper rolls. Increased arm opening/closing and lifting speeds and shorten the cycle time of paper roll changes significantly.

Auto Splicer

63-1N

63-1N Auto Splicer boasts faster paper splicing speeds at 584 meters per minute for medium paper. Equipped with the tension control system to prevent wrinkles and stabilize paper splicing.

Glue Machine

65J

The rider roll is placed with the glue applicator roll horizontally to reduce glue splash significantly. The glue amount applied on corrugated boards can be controlled optimally using the process commander.

Double Facer

66N

In order to operate various types of paper and flutes stably at high speed, Mitsubishi designs high performance 66N Double Facer incorporating unique technical know-how. It applies non-crushing air bag system to realize stable bonding regardless of flutes and production speeds.

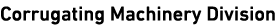

Gamma Changer

67-1N

67-1N Gamma Changer realizes "Gapless Order Change" during productions to change orders without interruption.

Gapless Order Change

Slitter Scorer

67N

67N Slitter Scorer is adapted tandem configuration and each station equips with two scorer shafts and one slitter shaft. Special scorer head is also available.

Double Cut Off

68N

68N Double Cut Off is equipped with two pairs of light-weighted knife cylinders with lower inertia to reduce energy consumption and achieve high production speed with high accuracy of cutting.

Double Stacker

DE245/DE248

Double Down Stacker dedicated for Mitsubishi corrugating machine is supplied in collaboration with NE Engineering, Italy.

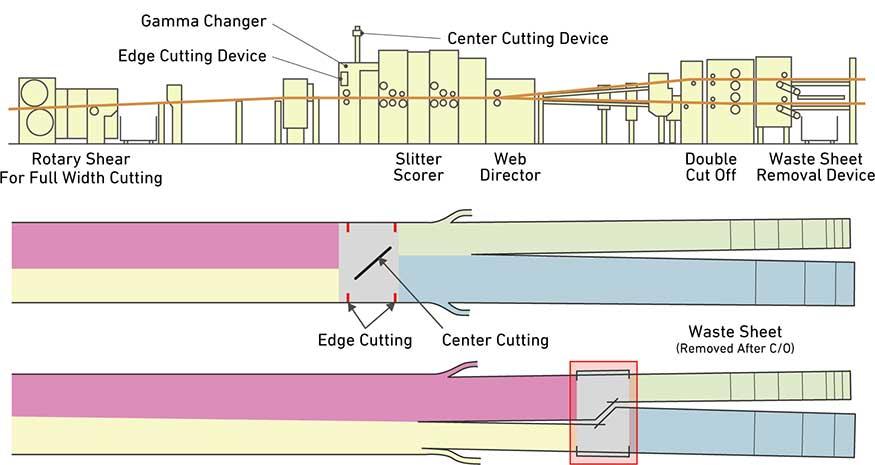

Production Control System

Sigma 2000N

Sigma 2000N production control system maximizes the performance of corrugating machine and ensures easy operations with high productivity for frequent order changes and short paper cycles.

Process Control

For brochures or more information about equipment, service offerings or parts, please email [email protected].