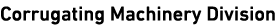

MC-100

We have engineered this new state-of-the-art Flexo Folder Gluer (FFG) that is ready to drive value and productivity in your box plant. The innovative stop and start wheel feeder provides continuous feeding, ensuring 100% alignment and quality control. The MC-100 runs at 300 boxes per minute with an ease of operation and enhanced quality control as well as the reliability you have come to know with MHI’s premier line of FFG’s.

EVOL Technologies Applied

Stable Running at 300 B/M

1) Feeding unit (L.E.F): LEF wheel zigzag arrangement

2) Transfer conveyor: Transfer conveyor with one piece vacuum belt

3) Folding unit: Upper vacuum belt, inlet lower belt

4) Drive and PLC: Siemens applied

Features

- 3 colors, 2 and 4 color options available

- Die cutting option available

- Stable running at 300 B/M

- Feeding Unit - LEF wheel zigzag arrangement

- Transfer Conveyor - One piece vacuum belt

- Folding Unit - Upper vacuum belt, inlet lower belt

- Counter ejector - One stage counter ejector

- Drive and PLC - Siemens applied

Benefits

- 2-3 operators

- Space Saving

- High quality and minimum waste

- Speed of 300 boxes/minute

- Easy operation and maintenance

- Production flexibility

- Minimized order change

- Possible die change during operation

- Accuracy: feeding - 1.0mm (0.04"), printing - .5mm (0.02"), folding - 3.0mm (0.12")

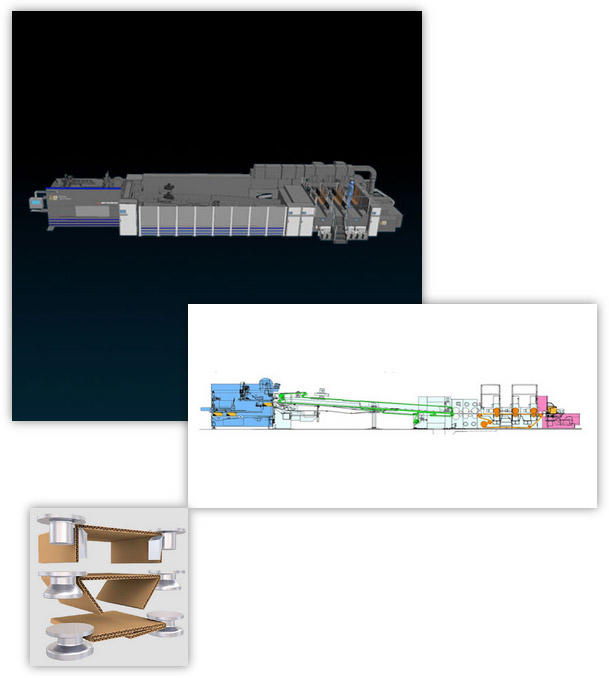

Specifications

| MC-100 Specifications | ||

|---|---|---|

| Maximum Machine Speed | BPM | 300 |

| Skip Feed | 150 | |

| Maximum Untrimmed Sheet | mm | 950 [1220] x 2555 |

| inch | 37.4 [48] x 100.6 | |

| Minimum Untrimmed Sheet | mm | 350 x 630 |

| inch | 9.8 x 24.80 | |

| Maximum Printing Area | mm | 960 x 2370 |

| inch | 37.8 x 93.3 | |

| Maximum Die Cut Area | mm | 960 x 2370 |

| inch | 38.6 x 84.6 | |

Dimensions

| MC-100 Dimensions | |||

|---|---|---|---|

| Min | Max | ||

| A | mm | 150 | 955 |

| inch | 5.91 | 37.6 | |

| B | mm | 90 | 785 |

| inch | 3.54 | 30.91 | |

| AB | mm | 300 | 1250 |

| inch | 11.81 | 49.21 | |

| C | mm | 60 | 498 |

| inch | 2.36 | 19.61 | |

| D | mm | 280 | |

| inch | 11.02 | ||

For brochures or more information about equipment, service offerings or parts, please email [email protected].