PACKAGING & ASSEMBLY

PACKAGING ASSEMBLY PROCESS

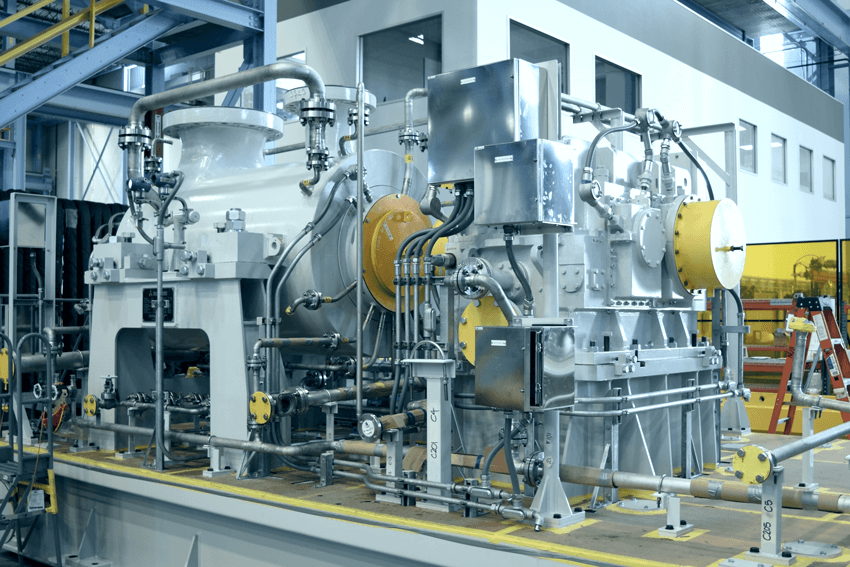

Our Pearland Works state-of-the-art facility offers customized compressor packaging, where we integrate the motor and gear, or steam turbine driver, on common or detached baseplates with the compressor turbomachinery. MCO-I engineering provides the detail design drawings, bill of materials (BOM’s), and support for fabrication and package assembly.

ONE-STOP PACKAGE ASSEMBLY PROVIDER

MCO-I Pearland Works packaging includes leveling and alignment of baseplates, and the location and fitting of piping and major equipment.

Package assembly consists of installing the major mechanical systems, the routing of lube oil piping and valves, interconnection of seal gas tubing or piping. Packaging of all major electrical components includes Junction Box layouts, instrumentation, cable and conduit routing, and supply of control systems. MCO-I can handle some of the largest compressor and turbine skids in North America with our 300-ton bridge crane and wide assortment of rigging equipment.

BENEFITS OF THE MCO PROCESS

- Products are geared towards the North American industry standards and NEC requirements

- Ideal Gulf Coast location makes for easy expediting, inspection, or witness activities for owners and EPCs

- Foreign trade zone for equipment on compressors for packaging purposes

- Competitive on-time deliveries

- On-skid packaging to reduce site installation work

- Utilization of domestic sub-vendors through USA procurement