HIGH SPEED BALANCE BUNKER

BALANCED PERFORMANCE IS BETTER PERFORMANCE

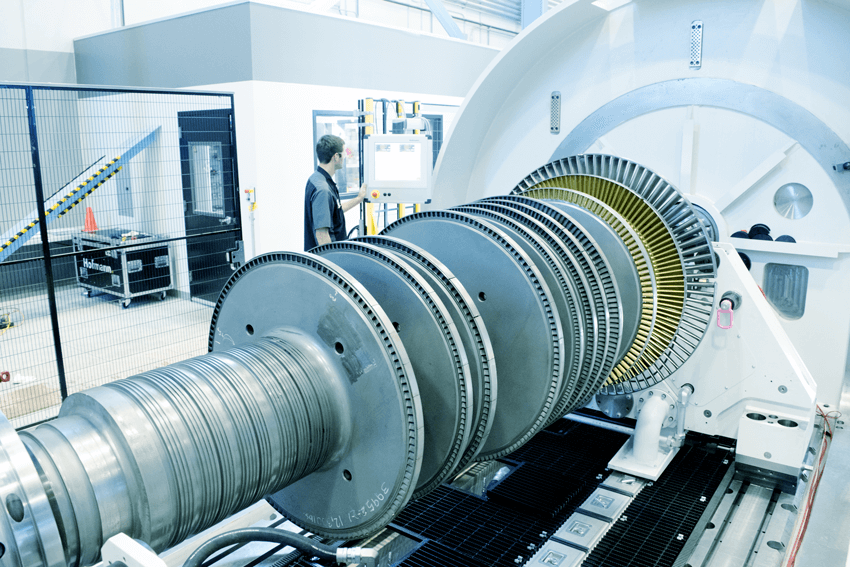

Excessive vibration from unbalanced rotors can result in a variety of productivity-limiting problems, including expensive downtime. At our onsite high-speed balance bunker, we correct unbalance and minimize vibration under field-like operating conditions; producing field-ready performance, reducing problems at start-up and helping you avoid costly field balancing.

Why High-Speed Balance

Low speed balancing is necessary before any rotor runs in service after manufacturing, repair, or long-term service to ensure it behaves in agreement with the rotor dynamic analysis. Performing a high-speed balance provides further confirmation. High-speed balancing evaluates rotor performance in a simulated service environment for behavior study. By spinning the rotor at operating speed, the effects of the remaining unbalance left after low speed balance is studied and corrected further ensures correct rotor behavior. Using both low and high-speed balance minimizes potential failure modes caused by rotor vibration.

The high-speed balancing machine accommodates rotor up to:

- 20,000 rpm

- 27,500 lbs

- 5.5’ diameter

- 19.5’ length

READ MORE ABOUT OUR SUCCESSES

Industrial compressors are run at incredibly high speeds under immense pressure every day.

Our state-of-the-art high-speed balancing bunker is more than just a test facility.