REVERSE ENGINEERING

INDUSTRY LEADING EXPERIENCE IS THE DIFFERENCE

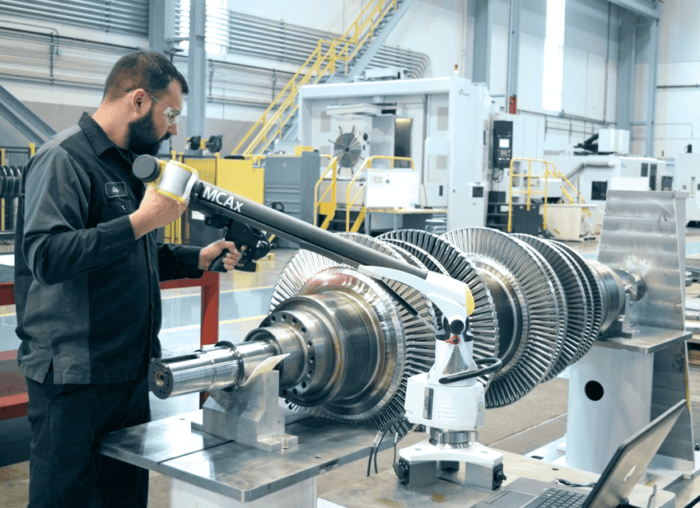

MCO-I relies on our industry leading OEM experience, design manuals, and proven designs when servicing all equipment. Our state-of-the art service center, Pearland Works, is equipped with the latest in reverse engineering measurement tools, used by trained engineers and technicians. We work in close partnership with the hundreds of steam turbine and compressor design engineers in Hiroshima to bring our advanced technology to your machinery.

Our standard approach is to gather dimensional data, construction details, and material information in order to understand the original design intent. If existing equipment has some problem or needs upgrade, we then can apply our proven designs within the existing envelope — injecting our Mitsubishi technology into any manufacturer’s equipment.

Aerodynamic Design

- CFD

- Internal re-rates and re-rotoring

- Steam turbine

- Centrifugal compressor

Complex Finite Element Analysis

- Structural redesign

- Harmonic analysis

- Thermal analysis

Rotor Dynamics

- Analysis

- Stability improvements

- Bearing design

Design Experience

- Standard component designs

- Manufacturing process standards

- Broad fleet history

Site Evaluations & Diagnostics

- Recommendations and evaluations for preventative maintenance, modernization, and upgrades