Triple-hybrid Power Generation System "EBLOX"

OUTLINE

EBLOX is a triple-hybrid system that combines an engine generator with renewable energy, such as solar, that contributes to decarbonization, and storage batteries to provide optimal distribution and stable control of power supply.

Realizing environmentally-friendly and stable power supply through combination of three power sources

The strength of EBLOX is the ability to stabilize the unstable power generated by renewable energy, such as solar, through the mix of three types of electricity source using an engine generator and storage batteries. This makes it possible to pursue a highly efficient, power supply with an environmentally-friendly and versatile distributed power source.

With the three types of power generating equipment called EBLOX and the control system called COORDY, we propose solutions to meet diverse power supply needs.

Solving the challenge of off-grid areas with a revolutionary power generation system

EBLOX is suited to remote islands, island nations, and regions such as Africa where power from grid is not available. EBLOX combines storage batteries to absorb and level out fluctuations in the power derived from renewable sources that are affected by weather and time of day and engine gensets that are not affected by nature as backup.

Voice of the development engineer

MHIET as the leader, EBLOX was completed through the comprehensive capabilities of MHI Group

Solar power generation is said to be one of cheapest power sources in the world today, and it does not emit CO2, as you know. However, it is very unstable as electricity cannot be generated when the sun is not shining. We used batteries to supplement it, but they were costly and took up space. This led us to consider a hybrid system using an engine to reduce costs and save space. Based on the technologies we cultivated to date, the ideal system was developed with the right combination of engine, solar, and storage batteries as a system that gives stable power supply, emits less CO2 and keeps initial cost low. The development was very challenging, but we were able to proceed smoothly as the MHI Group possesses advanced control technologies, including droop control and technology for coordinating different kinds of motors.

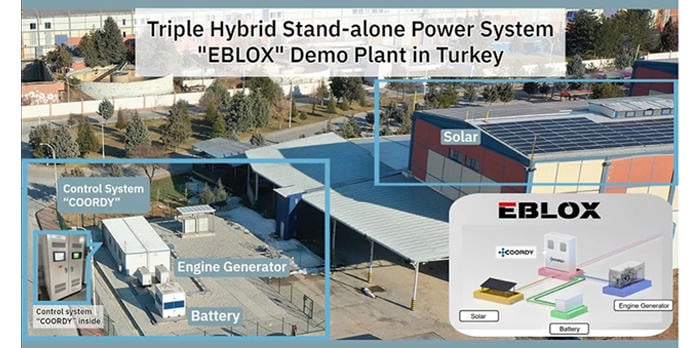

Partnering with Calik Holding of Turkey to introduce EBLOX in the African market

Off-grid areas with poor power supply networks stood out as places where the features of EBLOX would be useful, and one such area is Africa. Therefore, we made a proposal and presentation to Calik Holding, a leading Turkish conglomerate with which we have maintained a relationship for some time and which has a strong position in the African market. Calik Holding operates a wide range of businesses, including the energy-related infrastructure business. As the company has also been focusing on promoting solar power facilities in the African region, it took an interest in EBLOX, and the partnership between the two companies came about.

The project for the construction of an EBLOX demonstration plant in the factory of CALIK DENIM, a Group company of Calik Holding was then undertaken.

Completing the EBLOX demonstration plant after overcoming various problems and challenges

This was the first project in which MHIET has designed and constructed EBLOX jointly with an outside partner, and it involved some trial and error for communication on coordination of detailed division of roles and specifications. In addition, as our partner Calik started with no knowledge of EBLOX, they required significant technical assistance from us. In addition, as the onsite commissioning coincided with the pandemic, the number of employees we were able to send from Japan was also limited, and I ended up providing remote support from Japan. I didn’t have much experience with remote support itself, and the six hour time difference meant I also struggled with sleep deprivation. Generally,Monozukuri (manufacturing) is carried out by seeing the actual things at the actual site and knowing the actual situation, but with remote support it was very difficult to respond when problems occurred on site. Therefore, coordination of roles and specifications was solved through frequent exchange of engineering documents in remote online meetings. It was quite effective for ensuring good communication, which is a fundamental part of engineering, and documenting everything we exchanged.

The project was full of firsts with many difficulties and regrets. However, the final commissioning was successful, and we were able to complete the demonstration plant. In fact, I was unable to be present at the moment of handover. However, I was very happy and could finally relax when I heard that everyone at Calik was satisfied and people at MHIET said it was a good job and we had worked very well.

We want to bring EBLOX to communities all around the world suffering from power shortages to make the people happy and contribute to social development

Many regions in the world require independent power generation as they are not served by utilities transmission and distribution networks of electric utilities. For example, some regions, such as Africa, have not been able to develop because there were disruptions in the electricity supply in the past. The introduction of triple-hybrid power generation system EBLOX can lead to social progress such as improvements in living standards and the development of local industry. The introduction of EBLOX itself may be a small step, but it can lead to significant progress later. For me, this project has made me strongly aware of MHI’s principle of making a lasting difference to customers and communities worldwide. By promoting EBLOX to the world, we can deliver clean, low cost energy to off-grid regions and remote islands. I felt that this is our mission.

EBLOX is not actually a single finished product, but rather a combination of products that can be adapted to the customer's needs in order to provide the optimum energy solution. We hope to provide clean energy to the whole world through EBLOX.

At present, EBLOX demonstration plants have been established at the MHIET Sagamihara Machinery Works and at the factory of CALIK DENIM. These demonstration plants have been visited by many people interested in regions where power supply is a challenge and environmental issues.