About US

Message

Diamond Air Service Inc. (DAS), was founded on October 2, 1989 as a group company of the Mitsubishi Heavy Industries Ltd. (MHI) , which is in charge of microgravity experimental flights. At the time of establishment, we started our company activities by taking charge of a part of the repair work of the Ministry of Defense's aircraft, which was organized by MHI.

Since then, in the aircraft operation business, in addition to microgravity experimental flights, we have responded to customer needs in various fields that utilize aircraft, thereby contributing to the development of science and technology and the advancement of social infrastructure.

For instance, earth observation, atmospheric observation, exploration, photography, communication and broadcasting experiments, and disaster damage assessment.

In the aircraft manufacturing business, in addition to repair work, we have expanded the scope of our service to include new aircraft assembly work, and under MHI, we play a role in the manufacture and repair work of aircraft for the Ministry of Defense.

Through our two businesses of aircraft operation and aircraft manufacturing, DAS has accumulated management and technical capabilities in a wide range of fields related to aircraft, including operation, maintenance, design, manufacturing, and repair, and we provide products and services that satisfy our customers based on these capabilities. We will continue to contribute to society by ensuring safety and quality through the synergy effect of reliable safety management in the aircraft operation business and strict quality assurance in the aircraft manufacturing business.

Tomoe Nishigaya

President and CEO

Corporate Overview

| Company Name | Diamond Air Service Incorporation |

|---|---|

| Foundation | October 2, 1989 |

| Capital | 20 Million Yen |

| President | Tomoe Nishigaya |

| Employee | 514 (As of April, 1, 2022) |

| Certification | IS-BAO |

| Head quarter | 1 Toyoba Toyoyama-cho Nishikasugai-gun Aichi 480-0293, Japan (c/o Mitsubishi Heavy Industries Inc. Komaki South Plant) Phone:81-568-29-0020 Fax:81-568-29-0021 |

| Tokyo Office(Marunouchi Nijubashi Building) | 2-3, Marunouchi 3-chome, Chiyoda-ku, Tokyo, 100-8332, Japan (c/o Mitsubishi Heavy Industries, Ltd.) |

| Aircraft | BeechCraft Type BE200T (Twin Turbo-Prop) "Super King Air" BeechCraft Type BE200 (Twin Turbo-Prop) "Super King Air" Mitsubishi Aircraft International Type MU-300 (Twin Jet) "DIAMOND-I" Gulfstream Aerospace Model G-IV (Twin Jet) "Gulfstream-IV" |

History

| 1989 | October 2 | DAS was founded. | DAS was founded with the mission of conducting microgravity experiment flight operations and maintaining the aircraft used. |

|---|---|---|---|

| 1990 | February | We embarked on micro-gravity experiment flights on an MU-300 (JA8248). | We began conducting experiments with funds from a Grant for Promoting Science and Technology. NASDA (the present-day JAXA) began conducting micro-gravity experiments in September of the same year. |

| 1990 | August | We set up the Aircraft Repair Division. | We started performing periodical repairs for ejector seats and canopy parts for aircraft operated by the Ministry of Defense. (17 people) |

| 1991 | September | We carried out a search flight on an MU-2 (JA8737) to recover the TR-1 rocket after its launch. | We searched for the fallen head trunk of the TR-1A rocket over Tanegashima Island. The head trunk was discovered. |

| 1993 | August | Aircraft Repair Division. expanded its business. | We started performing structural repairs on the outer wings and tail assemblies of F-4 fighters. |

| 1994 | February | We carried out an OREX data acquisition flight over Christmas Island on an MU-300. | DAS's first overseas mission. We waited for OREX to fall into the Pacific Ocean and then succeeded in receiving data. |

| 1995 | December | We introduced the Gulfstream-II (JA8431: commonly known as the G-II). | We purchased a G-II from the East Japan Civil Aviation Bureau of the Ministry of Transport (the present-day Ministry of Land, Infrastructure and Transport) on December 5, 1995. The aircraft was transported from Haneda Airport to Nagoya Airport by air. |

| 1996 | April | We started equipment maintenance work and set up our Quality Assurance Section. | We began inspecting and servicing aircraft maintenance equipment used in the Komakiminami Plant. |

| 1996 | August | We placed X- and L-SAR systems aboard the G-II and modified the aircraft for observation missions. An observation flight ensued. | We carried out large-scale repairs and modifications of the G-II in order to install X-SAR (National Institute of Information and Communications Technology, NICT) and L-SAR (JAXA) systems aboard the aircraft. |

| 1997 | April | Aircraft Repair Division. expanded its business. | We began planning periodical repairs for Japan's self-defense aircraft under contract. |

| 1997 | August | Aircraft Repair Division. expanded its business. | We started aircraft disassembly work for the periodical repairs of Japan's self-defense aircraft. |

| 1998 | March | We carried out an arctic atmosphere observation flight on the G-II. | We carried out an atmospheric observation flight near the North Pole. The aircraft flew from Nagoya to Spitsbergen (lat. 78 degrees N) via Alaska over the North Pole. |

| 1998 | August | Aircraft Repair Division. expanded its business. | We began repairing helicopter tail rotor pylons as part of our periodical repairs for Japan's self-defense aircraft. |

| 1999 | November | We carried out a mobile communication experiment (N-Star satellite) on the G-II. | We built a radome of approx. five meters in height to install a parabola antenna for satellite communications on the upper part of the fuselage of the G-II. |

| 2000 | Throughout the year | We conducted an SAR concentrated observation flight on the G-II. | We surveyed crustal movements caused by the volcanic eruptions of Mt. Usu and Miyake Island and synchronized the G-II with NASA's DC-8 observation aircraft to conduct an observation flight. |

| 2001 | September | We carried out a search flight on an MU-2 to recover the H-IIA rocket fairing. | We carried out a search flight to recover the satellite fairing of the H-IIA rocket after its post-launch fall onto the sea. |

| 2003 | November | We flew over Antarctica to photograph a total eclipse from the G-II. | We flew a private jet to Antarctica for the first time ever to broadcast live images of a total solar eclipse for NHK in real time. |

| 2005 | July | We began flying simple zero-gravity experiment flights for the public. | We flew 18 flights on the G-II and three flights on an MU-300 from the start date up to the end of September 2014. |

| 2006 | March | We carried out an observation flight to record high-definition videotape footage on the G-II. | NHK videotaped the Japanese archipelago with a high-definition camcorder from the sky. We flew the G-II from Yonaguni Island to Hokkaido. |

| 2006 | September | We carried out a cloud observation flight on an MU-300 to prepare for a rocket launch. | We directly observed cloud configurations immediately before a rocket launch. |

| 2008 | March | We introduced and started operating a Beechcraft B-200T (JA8824). | We purchased a Beechcraft B-200T on May 9, 2007 from The Japan Coast Guard. We modified the aircraft for rain-making and atmosphere observation and carried out an atmosphere observation flight over East Asia. |

| 2008 | November | We obtained JIS Q 9100 and ISO9001 certificates. | |

| 2010 | July | We began preparations for operating our parts kit center. | We started preparations to operate the center with plans to open in April the following year. |

| 2011 | March | We carried out X-SAR observation flights to survey damage from Great East Japan Earthquake disaster on the G-II. | We carried out observation flights on March 12 and 18, 2011 (one day and one week after the earthquake struck). |

| 2011 | November | We conducted a Thai flood disaster observation (L-SAR) flight on the G-II. | We carried out a flood damage observation flight in Thailand at JAXA's request. |

| 2012 | February | We carried out a carbon aerosol observation flight on a B-200T. | We carried out direct measurements of PM2.5 levels in the East China Sea under a project carried out for three consecutive years. |

| 2014 | March | We introduced a second Beechcraft B-200 (JA20DA) and started aerial photography flights on the aircraft. | We conducted daily flights to shoot aerial photographs for map-making application. |

| 2014 | April | We set up the Aircraft Assembly Department. | Operations to construct new helicopters were transferred from MAP to the Dotoku Plant. |

| 2014 | May - July | We integrated the workshops of the Aircraft Repair Department. during renovations to the Komakiminami Plant. | We integrated workshops scattered all over the plant into the newly built No. 8 hangar to improve work efficiency. |

| 2014 | September | We relocated the head office and constructed the Engineering Department. building. | We renovated the Komakiminami Plant and moved the head office to another part of the plant. |

| 2015 | April | We set up the Logistics Department. | The Komakiminami physical distribution work of the former MHI ASL was transferred to the Logistics Department. The Logistics Department is responsible for receiving/shipping and packing components and performing physical distribution work in the plant. |

| 2016 | April | Aircraft Repair Department expanded its business. | The disassembly wok for the periodical repairs of Japan's self-defense aircraft after carrying-in was transferred to the Aircraft Repair Department. |

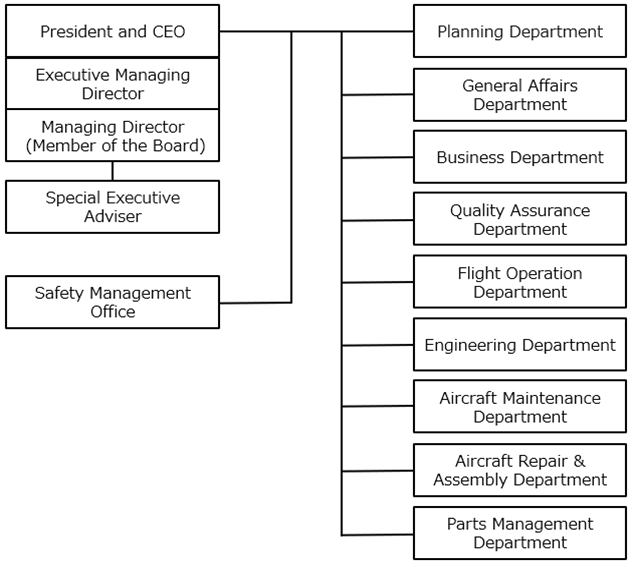

Organization

Access

Head quarter

| Address: | 1 Toyoba Toyoyama-cho Nishikasugai-gun Aichi 489-0293, Japan (c/o Mitsubishi Heavy Industries Inc. Komaki South Plant) |

|---|---|

| Access: |

In case of public transportationBus stop in front of JR Nagoya Station (Midland Square)

In case of Car DrivingFor the guest from Tokyo side Route 1

Route 2

|

Tokyo Office

| Address: | Marunouchi 3-chome, Chiyoda-ku, Tokyo, 100-8332, Japan (c/o Mitsubishi Heavy Industries, Ltd.) 10 minutes walk form Tokyo Station. |

|---|