Container Rinser/Sterilizing Equipment

Distributors :

Bottle washing machine

This equipment is used to wash returnable bottles (recyclable bottles). A high cleaning effect is achieved by combining processes of hot-water immersion, caustic solution immersion, and various jet injections. The design also reduces the usage of resources by recycling recovered water and heat.

Pasteurizer

The filling temperature in a beverage manufacturing line differs from product to product. One container is filled with a product at 1°C, near the freezing point, while another is filled with a product at a high temperature exceeding 80°C. This equipment restores the product to room temperature by showering it with hot or cold water. The equipment can also be used as a sterilizer by controlling the temperature.

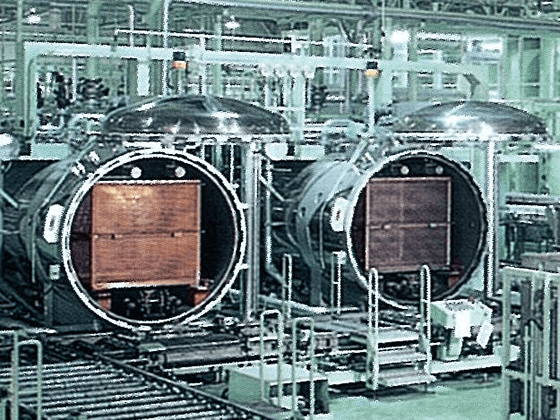

Retort sterilizer

This system retort-sterilizes coffee, tea, or the like in a container, killing robust germs that tend to survive ordinary sterilization using hot water. The autoclave equipment structure raises temperatures to high levels exceeding the boiling point. Two or more autoclaves are used for sterilization. As many as 50,000 to 60,000 cans of beverage are loaded into an autoclave and sterilized all at once.