Processing Machine

Distributors :

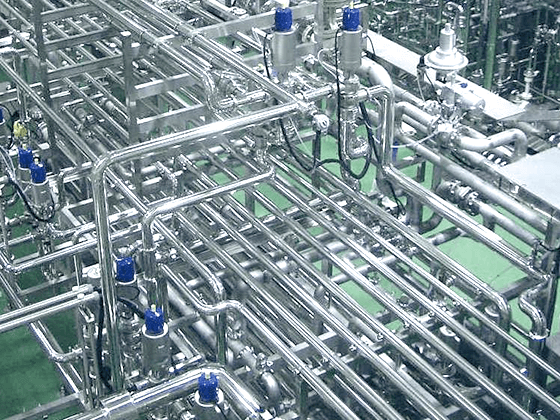

DBS unit

This beverage manufacturing equipment can manufacture beverages of many types, from carbonated drinks to fruit and lactic acid drinks. The space-saving system performs three operations in a single unit: deaeration of treated water, mixing with syrup at a constant ratio, and stable injection of carbon dioxide under pressure. The accuracy in controlling the syrup mixing ratio and pressurized carbon dioxide injection is outstanding. The ingredient capacities are easily adjusted and cleaning (sterilization) can be automatically performed.

- DBS: Deaerator, Blender, Saturator

Flash pasteurizer

A system to heat, sterilize, and cool various beverages using a plate heat exchanger or tube heat exchanger. The equipment performs various supervising functions to maintain the stability of sterilization conditions.

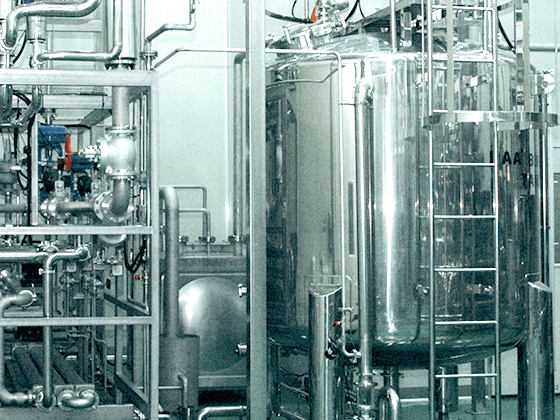

CIP equipment

This equipment automatically operates and controls the line cleaning/sterilization processes before and after a beverage is manufactured. The equipment transfers hot water or various chemicals at specified concentrations, temperatures, and flow rates.

- CIP: Clean In Place

Extracting/blending equipment

We propose the best blending facilities to manufacture tea, coffee, and syrup. The ingredients, quality, and production flow can all be controlled with a connected FA system.

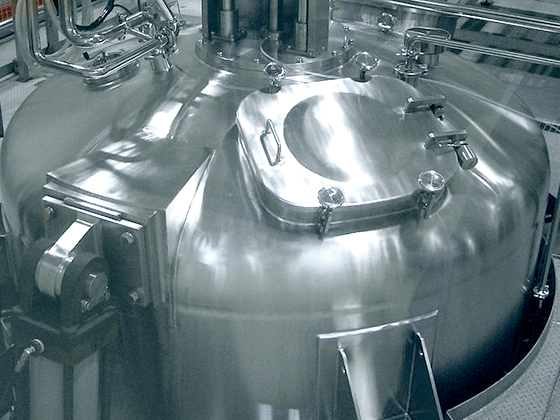

Aseptic processing equipment

Aseptic processing facilities equipped with environmental sterilizing systems (aseptic water sterilizing equipment and chemical agent dispensing equipment), aseptic product sterilizing equipment, and a sterilizing tank. The system creates an aseptic environment according to a prescribed environmental sterilizing program. Our company selects an optimal cleaning program to minimize the non-production time, as well as the best system architecture to control the aseptic environment in the customer's plant.