Pouch-Filling Machine/Molding-Filling Machine

Distributors :

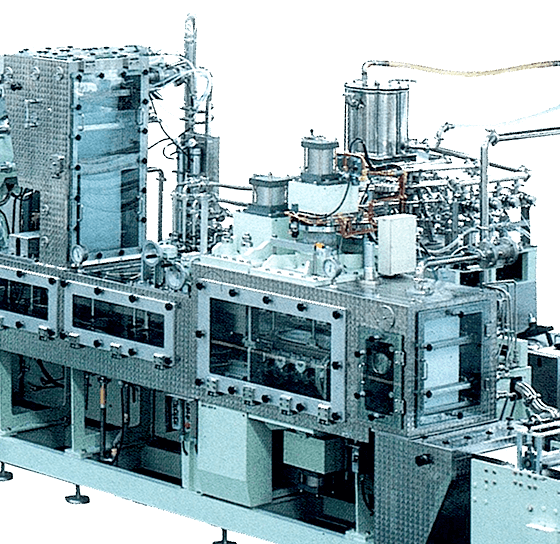

Pouch filling machine

This machine fills retort pouches and other soft-packaging containers with either liquid or solid. The machine can manufacture pouches of various forms, including standing pouches that must support their own weight. The machine can also manufacture pouches that keep liquids or solids in an aseptic condition. The high-speed type can manufacture up to 120 pouches per minute.

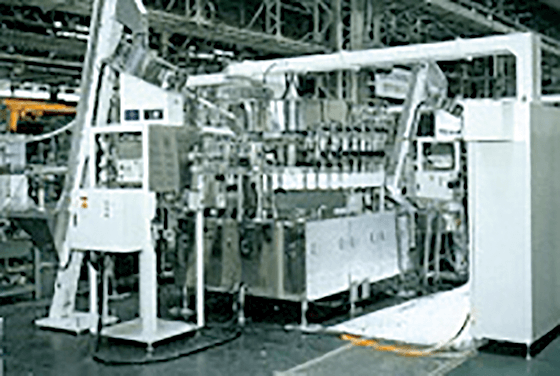

Spout Pouch filling machine

This machine can fill soft-package, spouted containers with pulpy fruit drinks, jelly-type beverages, and barbecue sauces, as well as ordinary soft drinks. The introduction of a servo-driven piston has enabled stable, high-speed, high-accuracy filling. The machine can manufacture one hundred and fifty 300ml pouches per minute when operating at high speed.

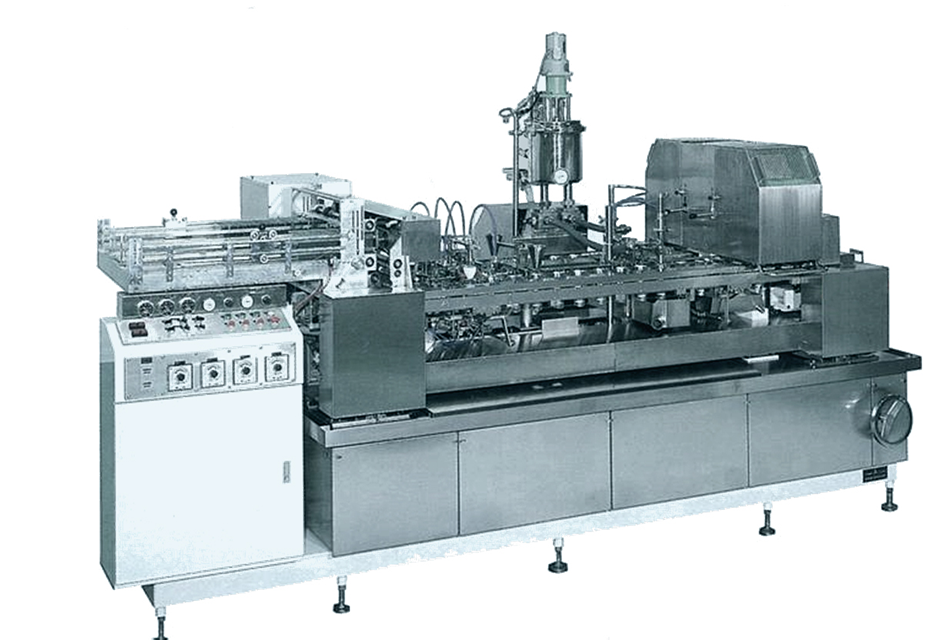

Portion pack aseptic packaging machine

This machine fills gum syrup, milk, cream, or non-dairy creamer into the portion packs that come with coffee or tea. The machine molds a roll of plastic sheet into the container, fills the container with liquid, welds over a sheet cover, and punches the container out. The machine can manufacture portion packs designed to keep a liquid in an aseptic condition. The high-speed type can manufacture up to 2,100 portion packs per minute.

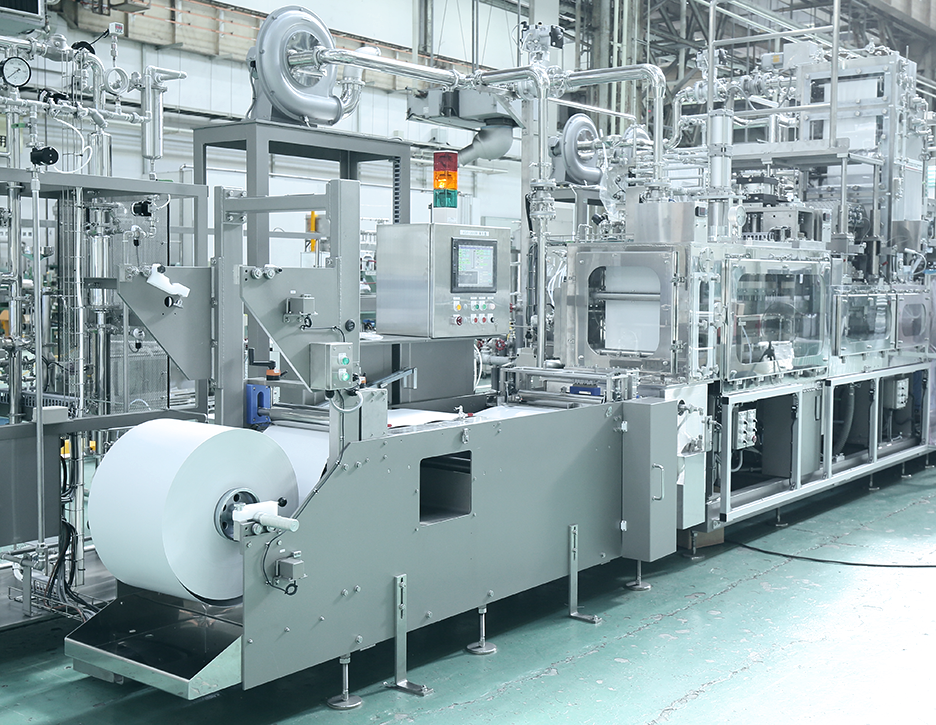

Bag making-filling-sealing machine

A single machines performs all of the steps from making the bag from the film fed out a film roll to filling the bag with a liquid product. Our high-speed, high-performance machines serve in a wide range of fields, from foods and beverages to medical and pharmaceutical supplies.