PRODUCTS & SERVICES

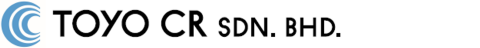

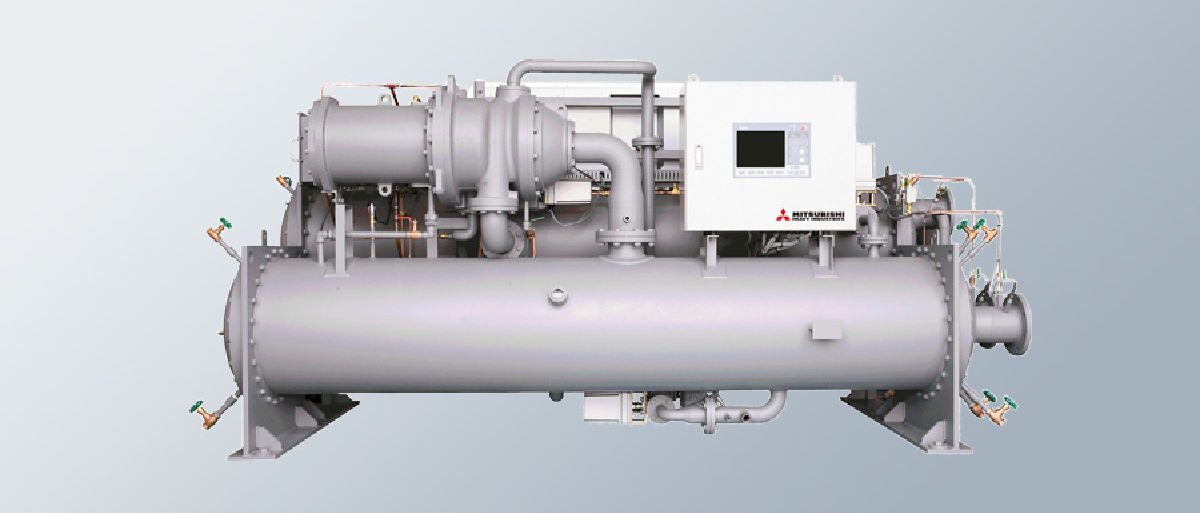

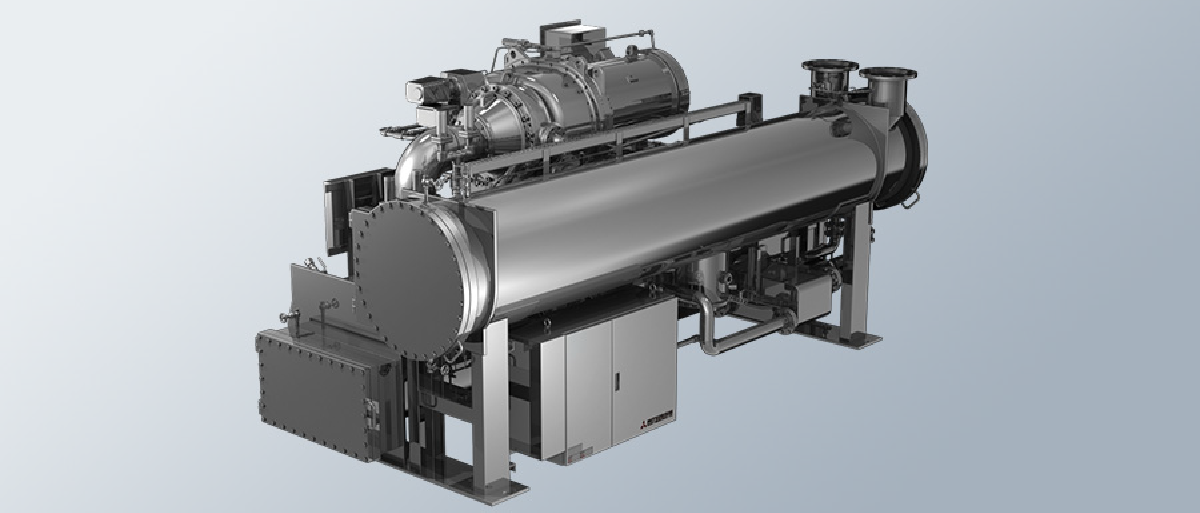

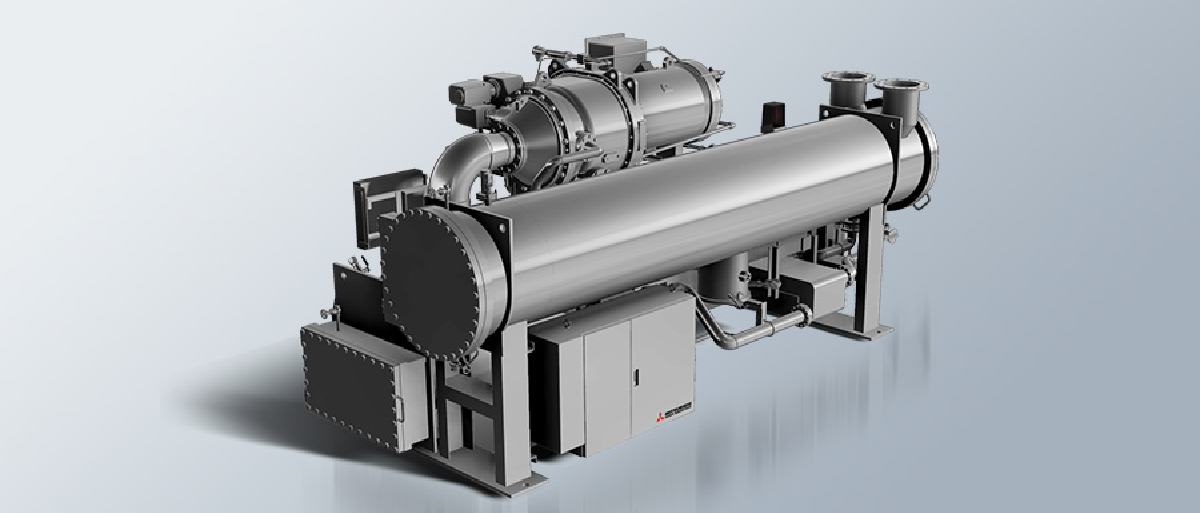

Centrifugal Chillers

Centrifugal chillers are used for air-conditioning of commercial facilities (i.e. office buildings, hotels, shopping malls and district cooling and heating systems),as well as air-conditioning and manufacturing process of industrial factories (i.e. semiconductor, automotive, textile, food and beverage industries etc...) Mitsubishi Heavy Industries centrifugal chillers can achieve the significant energy saving and CO₂ emission reduction along with preventing ozone layer depletion and global warming.

Inquiry

For inquiries about centrifugal chillers, please fill in the designated chiller inquiry form (Excel) and send the inquiry form to the contact address [email protected].

High Efficiency Centrifugal Chillers

High Efficiency Centrifugal Chillers with Low GWP Refrigerant

MyHIJAU

MyHIJAU Mark is Malaysia’s official green recognition endorsed by the Government of Malaysia, bringing together certified green products and services that meet local and international environmental standards under one single mark.

Registered green products and services will be listed in the MyHIJAU Directory which as a reference for green procurement (including Government Green Procurement; GGP and Green Private Purchasing; GPP), green incentives (including Green Investment Tax Allowance; GITA and Green Income Tax Exemption; GITE) and related green technology initiatives.

MHI Centrifugal Chiller are certified by MyHIJAU and are committed to achieving a sustainable future. By choosing environmentally friendly products, you can help protect the global environment and be received a various merit.

Chiller Services

Preventive Maintenance for MHI Chiller

Preventive Maintenance Programs by Mitsubishi Heavy Industries Thermal Systems, Ltd. (MTH) keep your centrifugal chiller running with efficiency and confidence. Offering you maintenance programs to meet your needs with our knowledge and experience from genuine manufacturer.

- Preventive Inspection

A Customer Service representative will assist you during regular business hours.

- Annual Maintenance

Annual Maintenance during a non operating period will be an important opportunity to secure future operations.

- Tube Cleaning

Maintain maximum operating efficiency by removing foreign debris and scales.

- Lubricant Oil Analysis/Replacement

Checking for oil deterioration and replacing deteriorated oil is necessary to ensure proper chiller life.

- Vibration Measurement / Analysis on Compressor

Check whether there is an abnormality in the compressor and motor.

- Eddy Current Test for Condenser / Evaporator tube

The tube will be checked for remained thickness or damage.

- Testing and Analysis (Electrical, Water & etc,)

- Compressor Overhaul

Disassembling compressor and recondition or replace consumable parts with new one to ensure stable operations.

TOYO CR can perform overhaul work at our own factory.