Safety Activities

Safety Quality Activity

The safety quality management system has been established in accordance with JEAC4111-2009 to protect employees, the public, and the natural environment from a radiation disaster by maintaining proper operating conditions, preventing the outbreak of an accident, and mitigating the consequences in the event of an accident.

The safety quality management system is designed so that all employees work together with the objective of achieving a higher level of safety and quality by using the PDCA (plan-do-check-act) cycle.

For improving safety and reliability, we are periodically conducted nuclear facility peer review by Japan Nuclear Safety Institute.

Nuclear Criticality Safety Control

Nuclear criticality is achieved when the fission chain reaction of fissile material such as Uranium becomes self-sustaining resulting in the release of a large amount of energy and radiation. The MNF plant utilizes low enriched uranium which has an low level of risk of an accidental criticality; however, this risk is mitigated by controlling the mass and geometry of nuclear material handled at the plant.

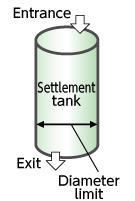

Geometry control

Uranium is handled in equipment which is geometrically shaped to physically prohibit the occurance of criticality.

This figure illustrates an ADU precipitation tank (cylindrical) used in the reconversion process. The diameter of the cylinder is designed so as to make criticality impossible.

Mass control

The amount of material handled at one time is restricted so that it is physically impossible for a criticality to occur. The limit to the amount handled is established such that there is no less than a factor of 2 safety margin against criticality.

- The facilities within the plant are periodically inpsected to be sound.

Periodical training of employees is conducted appropriately.

Compliance to the established rules at the plant.

Fire Prevention and Disaster Prevention Activity

The goal of the Emergency Plan is to ensure the safety of people and structures in order to reduce any possible damage to human or physical assetts. Through consistent fire prevention control, together with the proactive prevention of fire, earthquake and other disasters. The Emergency Management System was established with the goal of achieving, maintaining, and measuring the improvement of fire prevention in the Tokai region.

Industrial Safety and Health Activity

We have established an Occupational Health and Safety Management System based on the Ministry of Health and Labor's "Guidance on Occupational Health and Safety Management Systems".