What our products and service?

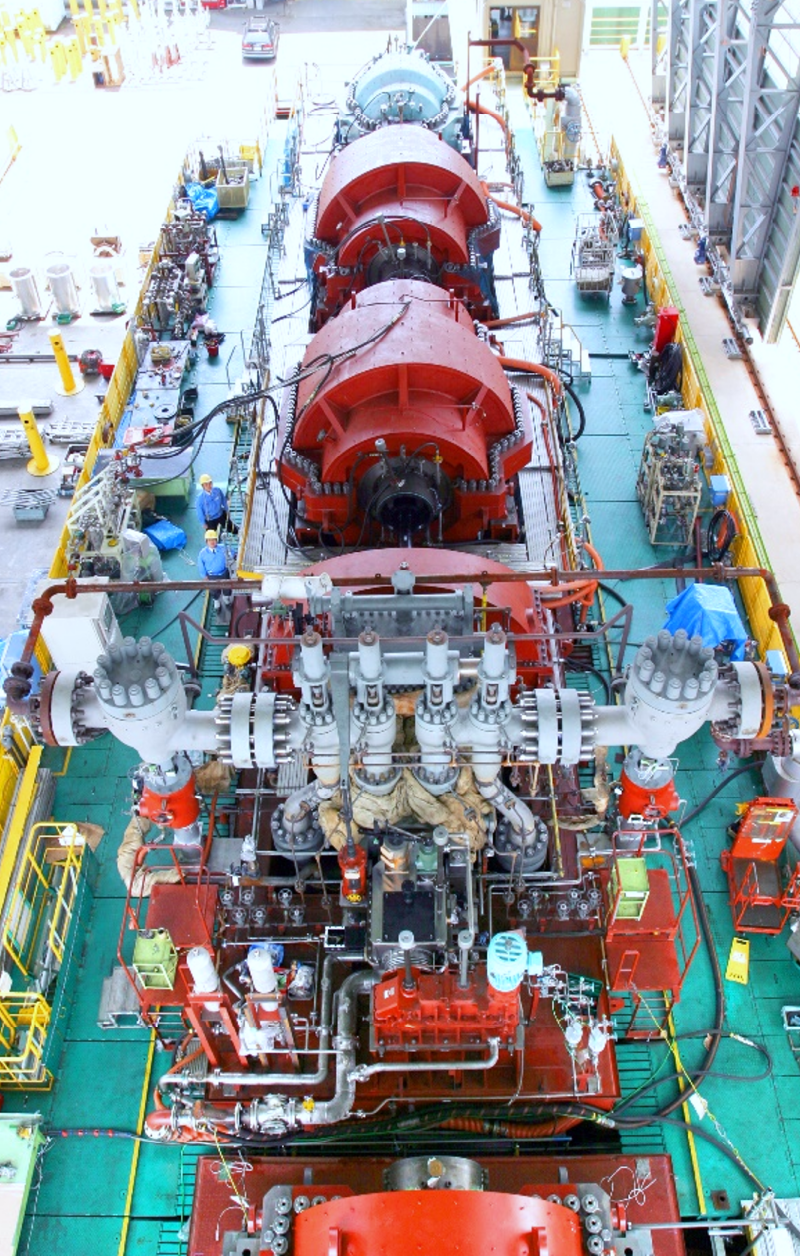

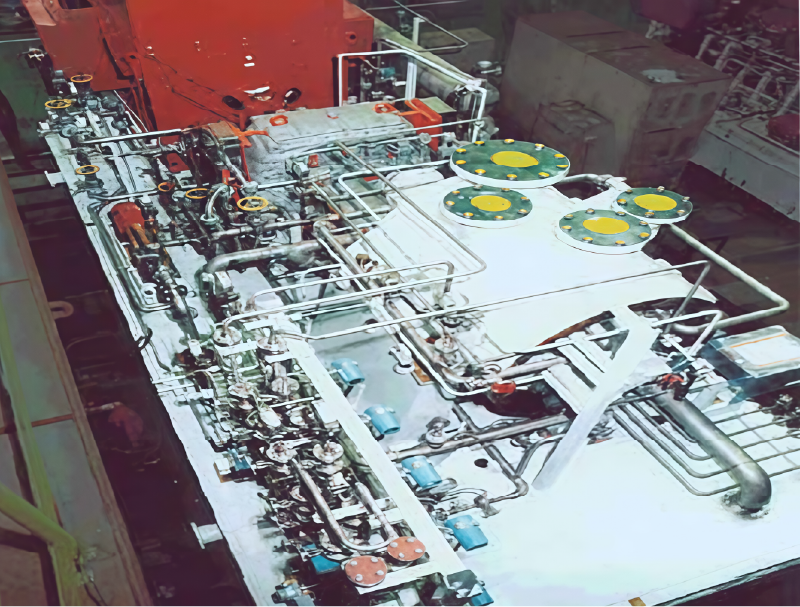

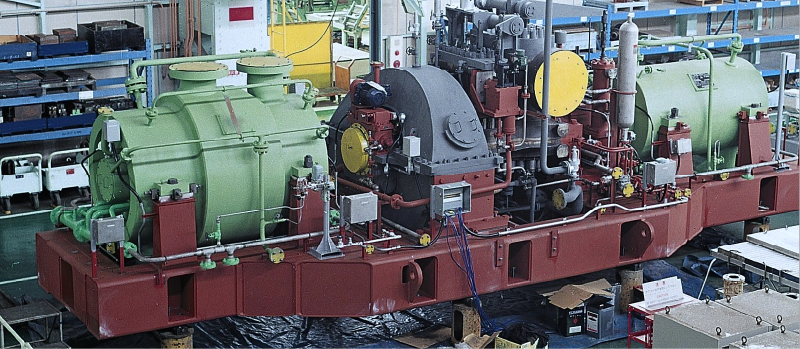

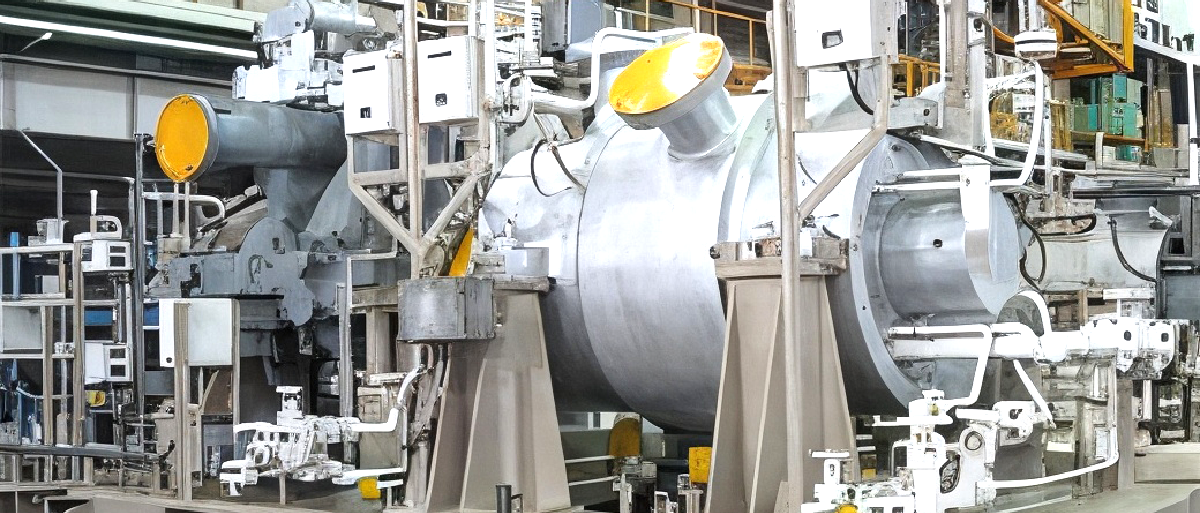

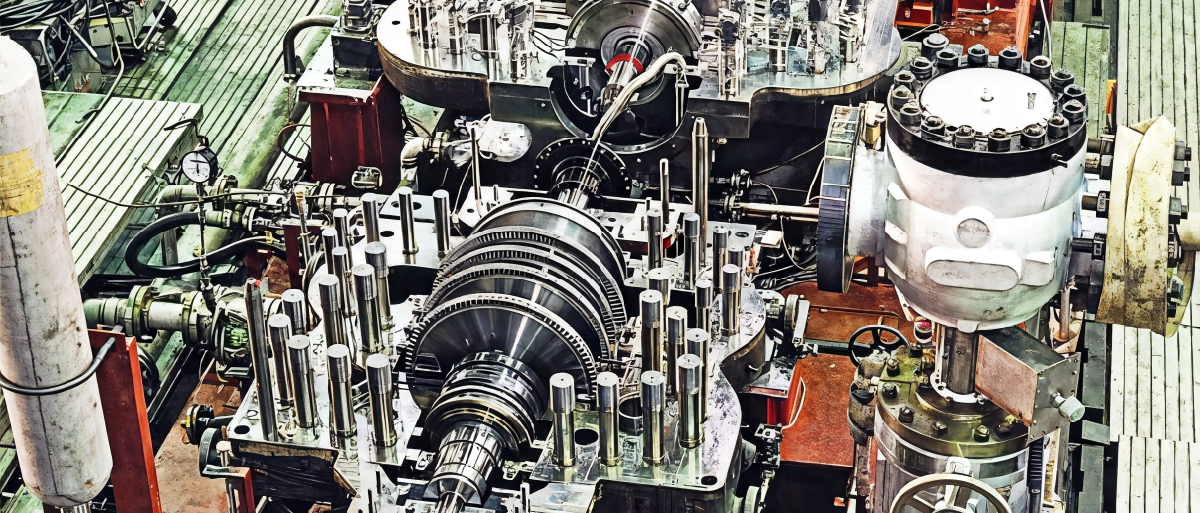

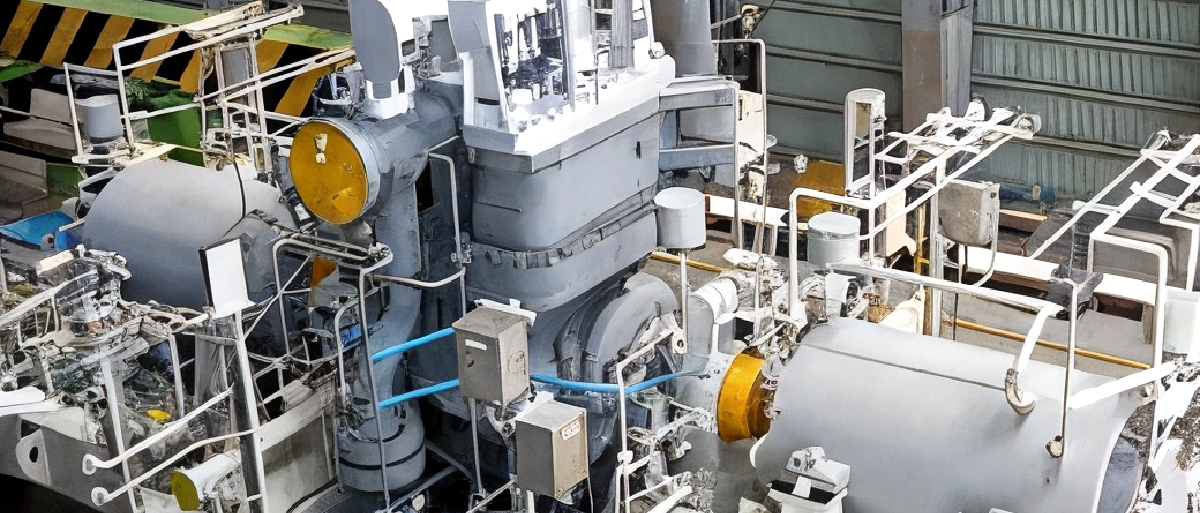

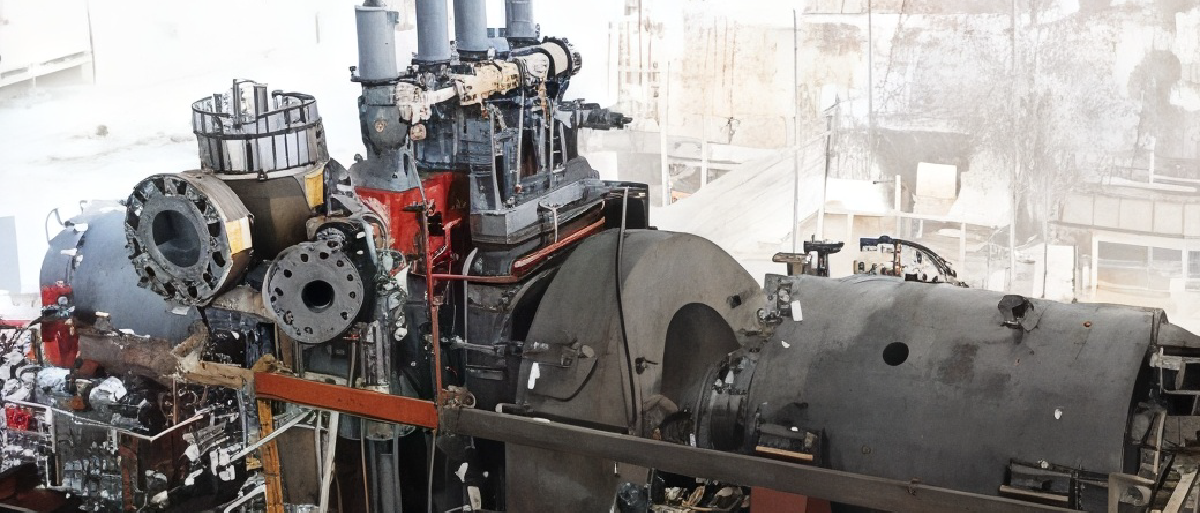

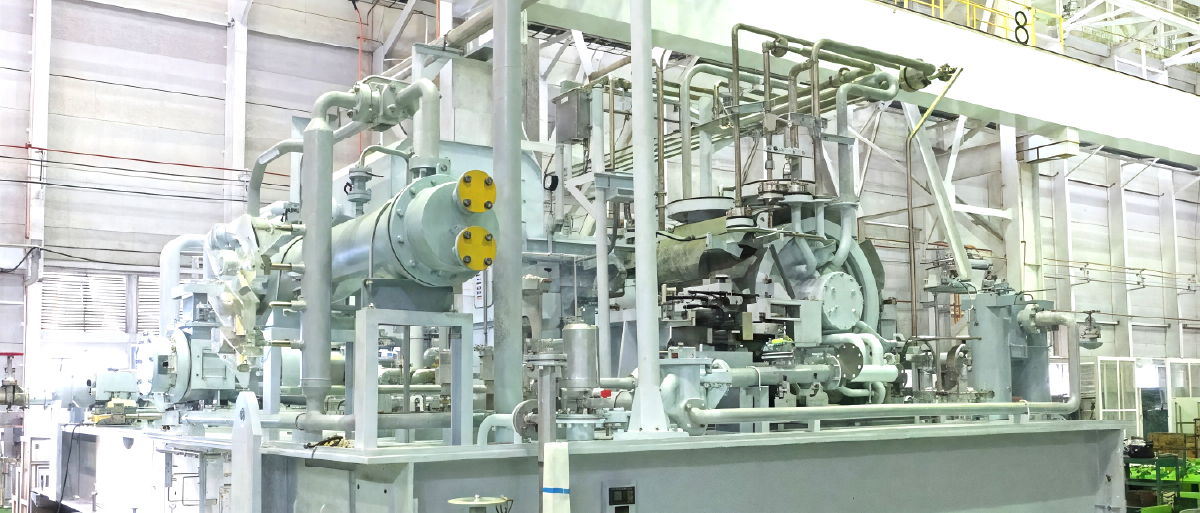

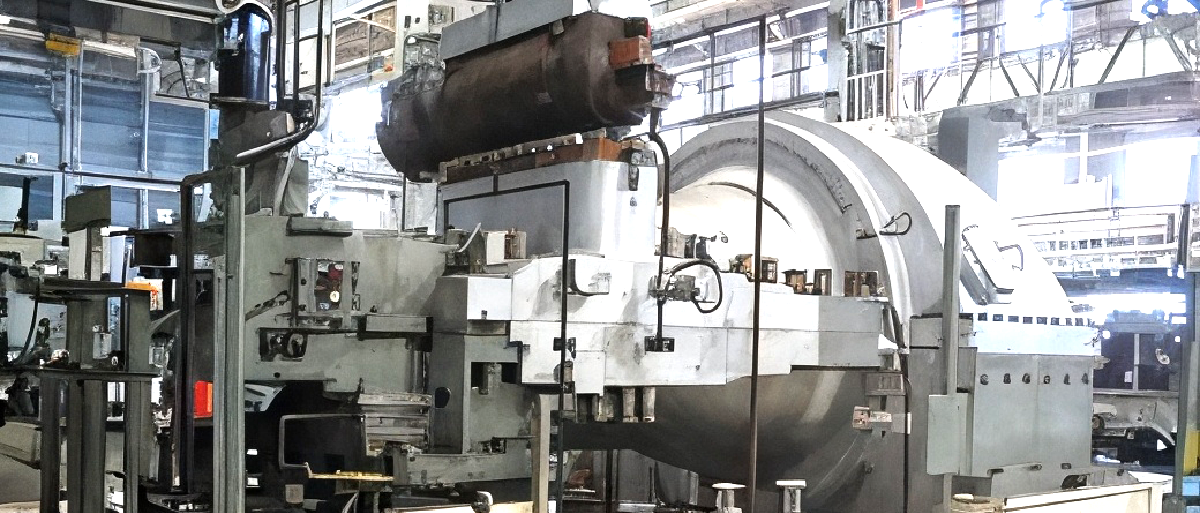

Compressors and turbines are one type of "turbomachinery." While it is somewhat difficult to provide a precise engineering definition of this term, one description is "a machine which performs continuous energy conversion between fluid energy and mechanical energy by means of a rotating impeller." Machines that we use everyday, such as fans, propellers, turbines, pumps, water wheels, windmills, jet engines, and automobile turbo chargers are all types of turbomachinery. The turbomachinery manufactured by Mitsubishi Heavy Industries Compressor Corporation (MCO) used for the gas and petrochemical industries of these machines. Specifically, these products include the compressors which compress the air and gas necessary for production at production facilities such as chemical plants, gas plants, and steel works, as well as the steam turbines which drive these compressors. These products are active in energy industry and petrochemical industry fields all over the world. The rotors we produce range up to diameters of over 2 meters and weights exceeding 10 tons. MCO possess the world-leading design and production technologies that are needed to ensure high-speed and stable operation of these rotors.

Applications of MCO products

MCO’s compressors and steam turbines are installed in;

- various kind of chemical plants (including refrigeration system) such as ethylene plants and fertilizer plants (ex. SABIC)

- oil & gas field such as refinery, LNG plants, gas production facilities and gas pipelines (ex. ARAMCO plants)