News

MHI-MME retrofitted the turbochargers onboard A.P. Moller's oil tanker to reduce fuel consumption during slow-steaming

Mitsubishi Heavy Industries Marine Machinery & Engine Co., Ltd. (MHI-MME) retrofitted the main engine turbochargers by installing the novel Variable Turbine Inlet system (VTI) onboard Maersk Ingrid, a 318 kDWT crude oil carrier (VLCC) owned and operated by Maersk Tankers. The retrofit was carried out during Maersk Ingrid's first dry docking in May 2013.

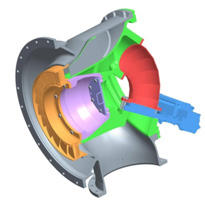

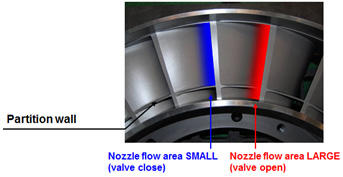

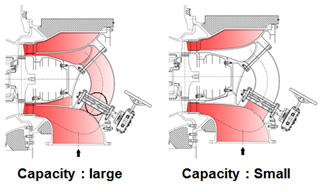

VTI is a system which was developed for MET turbocharger series by MHI-MME. The gas inlet passage is equipped with an on-off valve which changes turbine capacity in two stages by admitting the exhaust gas into two separated concentric segments of the nozzle ring. When the vessel is operating under slow steaming mode, scavenging air pressure of main engine is increased by closing the on-off valve which thus decreases fuel consumption rate and CO2 emission. MHI-MME has been delivered more than 10 VTI systems for new shipbuilding projects. However, it was the first case that VTI system was retrofitted to turbochargers on a vessel in service.

Maersk Ingrid's main engine is of type Wärtsilä 7RTA82T applied with 2 Mitsubishi MET71MA turbochargers. These turbochargers were manufactured by Hyundai Heavy Industries, under license. At this time, MHI-MME supplied the gas inlet inner casing with VTI system for the vessel. The retrofit work was completed in 4 days. NOx emission was measured at sea trial after retrofit, and confirmed to comply with IMO Tier 2 regulations. Moreover, we confirmed the expected fuel consumption reduction effect at the Low-load operation without sacrificing the performance in the high-load range was confirmed. Mr. Vaibhav Chavate, who leaded this first retrofit project in Maersk of A.P.Moller, concluded that the fuel consumption reduction was 1.6 - 3.2% in the load range of 10 to 50% MCR and the pay-back period is attractively short. The application of VTI to further vessels with MET turbochargers is now under consideration by A.P. Moller.

VTI Turbocharger is not only a suitable system for slow steaming, but the simple structure which results in high reliability while achieving low costs and easy maintenance. In addition, VTI system is easy to retrofit on conventional MET turbochargers by just adding a nozzle and an on-off value to the exhaust gas inlet area. And the greatest strength is the low fuel consumption at both high and low cruising speeds by operating the on-off valve.

MHI-MME entered the market with a water-cooled turbocharger in the 1950s. In 1965, the company developed a non-cooled turbocharger, subsequently adopting the brand name of "MET Turbocharger." Since then MHI-MME has introduced various high-efficiency, high-performance turbochargers to the market and expanded the MET Turbocharger series portfolio. Owing to its high-efficiency, simple and easy-to-maintain structure and outstanding reliability, the MET Turbocharger has established a solid track record and is highly esteemed by its users.

- Solution: Slow Steaming Operation / VTI Turbochargers

- Products: MET Turbochargers