News

Mitsubishi Heavy Industries Marine Machinery & Equipment Co., Ltd. has expanded its service offerings with a new menu aimed at extending the lifespan of our equipment installed on LNG vessels. Below are some of the maintenance options we offer. As LNG vessels age, there can be situations where regular maintenance alone is insufficient for the adequate preservation of various equipment. In addition to the services introduced here, we are expanding and providing a range of service options to meet the needs for extending the lifespan of LNG vessels. If you have any requests or inquiries, please contact our service sales office at [email protected].

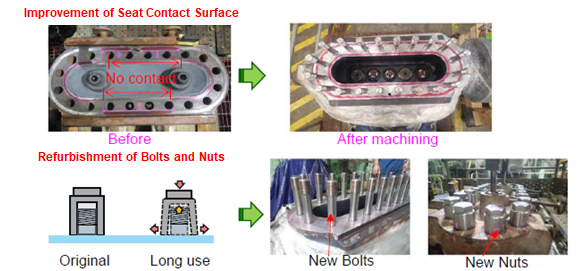

Ahead Nozzle Valve Refurbishment

Over years of operation and inspection, the seat surfaces and tightening bolts and nuts of the Ahead Nozzle Valve cover on the main turbine may show signs of deformation. In some cases, this has led to steam leakage on operational vessels. Based on our inspection experience, we recommend refurbishing the seat surfaces, replacing the tightening bolts and nuts, and adding washers around 15 years after ship delivery. We encourage you to consider this for the safe operation of your vessel.

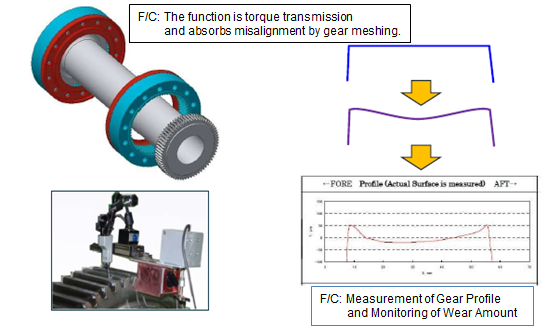

Flexible Coupling Wear Diagnosis

The flexible coupling (gear coupling), which transmits torque from the main turbine to the reduction gear, can experience gear tooth surface wear due to over operation. For vessels that are over 10 years old, we use specialized measuring equipment during docking periods to monitor wear levels and assess the overall condition. We encourage you to consider this service for enhanced safe operations.