News

Transition and Development in the Waste Heat Recovery Systems for Main Engines - and now, for the new generation WHRS

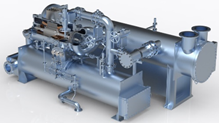

Mitsubishi Heavy Industries Marine Machinery & Equipment Co., Ltd. has developed a state-of-the-art binary power generation system based on Organic Rankine Cycle technology (WHR-ORC system) (*1). It is mainly for waste heat recovery from sulfur-free fuel main engines, which are starting to become mainstream in the transition to a low-carbon and decarbonized society.

The amount of waste heat that can be recovered from main engines continues to decline due to continual improvement of the fuel efficiency and environmental performance of main engines. we have been improving and developing waste heat recovery systems in accordance with such trends, marking many achievements.

The recently developed WHR-ORC system is our cutting-edge ORC system, developed through such efforts.

First-generation systems

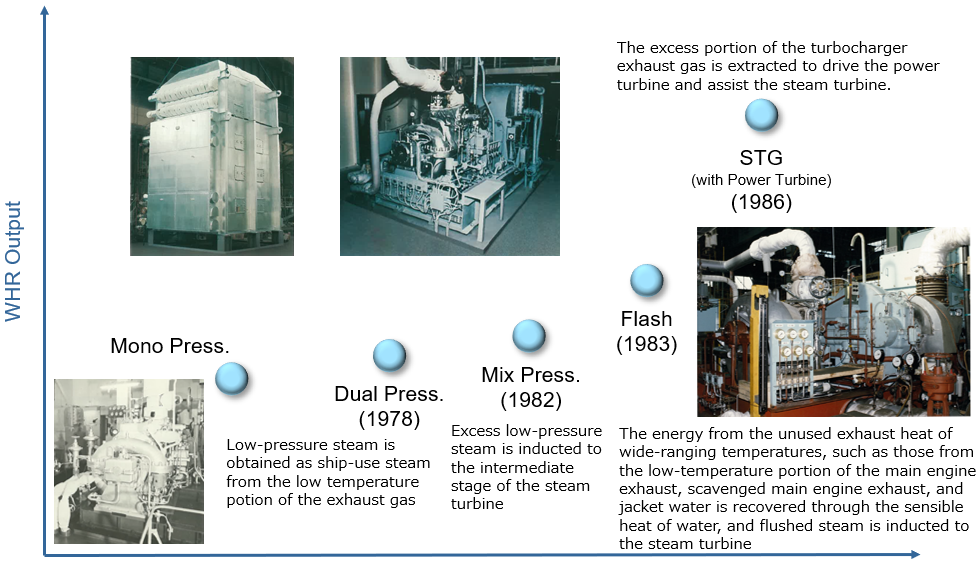

Since diesel engines first started to be used as the main engines of large vessels, economizers and other means have been utilized to recover exhaust gas energy by converting water into steam for utilization in power generation systems. The demand for energy efficiency increased after the oil crisis. Efforts made particularly in response were the improvement of main engine fuel efficiency and the upgrading of ship hull designs. With such changes, there were drastic reductions in exhaust gas temperatures and main engine required outputs. This resulted in a significant decrease of waste energy. Even under such circumstances, customers’ needs to use the energy contained in main engine exhaust gas to meet the onboard electrical demands of a ship remained. Various systems were therefore improved and adopted. However, the adoption of waste heat recovery systems decreased once the rise in fuel prices settled down. Even when adopted, relatively simple waste heat recovery systems, such as dual pressure or mixed-pressure types, became predominant.

Our WHRS Track Record(First- and second-generation sytems)

Second-generation systems

Tubine Generator

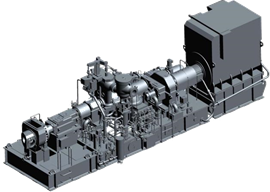

Beginning of 21st century, with growing environmental conscious and the rise in fuel prices, interest in Super Turbo Generating (STG) systems grew once again, mainly for large-size containerships, which have larger onboard electrical power needs. STG systems are waste heat recovery systems (WHRS) that integrate a power turbine that utilizes the excess efficiency of a turbocharger used in power generation and conventional steam turbines. This STG system utilizes both extraction gas and exhaust gas to strengthen coordination with main engines and enable optimal control, which lead to a further improvement of energy efficiency on board. To respond to onboard electrical power needs more flexibly, an energy-saving power generation package, that combined the use of an STG system and shaft generator, has been an alternative solution.

Third-generation systems

WHR-ORC system (Model : MWT-ZD600M)

As a result of the further improvement of main engine fuel efficiency, constant slow steaming, and compliance with NOx emission regulations, the amount of main engine exhaust gas energy that can be used, decrease significantly. With this, the use of WHRS declined as they were no longer able to cover onboard power needs sufficiently and effectively. Recently, sulfur-free fuel Ships, such as LNG and methanol are increasing and its fuel price hikes also continued.

Responding to green-house gas emissions reduction became a global challenge, as well. Amid such circumstances, with the aim of making the system a main force in next-generation WHRS, we developed a WHR-ORC system that can make effective use of exhaust heat of 150 degree or lower, which was not easily extracted in the past, due to sulfur dewpoint corrosion concerns.

(*1)WHR-ORC:Waste Heat Recovery – Organic Rankine Cycle