MHI Launch Services: Our Services

MHI Launch Services

Mitsubishi Heavy Industries is a launch vehicle manufacture and launch services provider to ensure the "secure" delivery of a customer's payload (satellite) to "a target orbit" on "a target date." These services commenced in 2007 with the execution of Flight No. 13 of the H-IIA Launch Vehicle. We started the Launch Services of the H-IIB in 2013. This results in expending our launch services activities.

The greatest strength of MHI's Launch Services is their comprehensive scope. The services coordinate the entire process from launch vehicle manufacture to interface between the spacecraft and Launch Vehicle, program management, and execution of the launch campaign. Satellite manufacturers and satellite operators deal directly with MHI engineers, the people most familiar with MHI's launch vehicle technologies and systems. This direct liaison enables consistent and accurate judgment throughout the process. MHI continues to make reliability the core of its Launch Service with a focus on usability from the customer's viewpoint.

Three Objectives of the Launch Services and Our History of Successes

- 1. Usability for customers

- As a result of their diverse experience in launch vehicle development and launch operations, MHI's expert engineers offer comprehensive services to fully coordinate every step of the process, from launch vehicle manufacture to adjustment of the launch-vehicle-to-satellite interface, support for satellite preparations at the launch site, and launch campaign. A Program Manager serves as an overall supervisor for the Launch Services and assigns a Mission Manager to take charge of services for each customer's satellite as a point of contact. The Mission Manager is responsible for the contract, service operations, and schedule management for individual programs and works closely with the launch vehicle manufacturing and launch operation teams to effectively coordinate the various steps necessary for a reliable launch. The system takes full advantage of MHI's outstanding knowledge, experience, and teamwork to provide customers with the highest quality service.

- 2. Extreme launch reliability for failsafe delivery to the target orbit

- The H-IIA Launch Vehicle has an extremely high orbit-injection accuracy and the versatility to launch satellites into various types of orbit.

- 3. Secure delivery on the target date

- A launch that isn't rescheduled after the start of launch operations is called a 'on-time Launch'. More than 90% of 'on-time Launch' ratio except a small number postponed by weather has been achieved since MHI Launch Services started. This has earned MHI a reputation for schedule maintenance. The launch window, the window of time when a launch is possible, varies according to the payload's target orbit. In some cases, the launch window is about two hours. In other cases, when the payload is to be delivered to a moving target such as the moon or the ISS, the launch must be executed within a one-second level of accuracy. We meet this stringent launch condition and are garnering a history of reliable launches.

Leaflet

Service Contents

MHI provides customers a single contact point for the arrangement of simple, complete, and consistent services at every mission phase, from pre-contract coordination to the actual launch. One of our roles, as a provider of launch services, is to coordinate between manufacturers, insurance companies, the Japan Aerospace Exploration Agency (JAXA), relevant ministries, and others involved.

MHI entrusts subcomponents of the H-IIA launch vehicle to related manufacturers and works with insurers to arrange launch insurance based on the customer's needs. We also handle regulatory items related to radio waves and dangerous objects by filing applications for approvals with the relevant ministries. Range safety/control operations, downrange operations, launch facility maintenance, and many other operations are entrusted to JAXA for the strongest assurance of reliable launches conformance with launch schedules.

MHI's Main Services

- Program Management

- MHI can generally launch a customer's satellite about two years after signing a contract. Once the launch vehicle is built according to the satellite specifications, we test it by various analyses, inspections, and reviews. Program management provides comprehensive control for schedule assurance and a reliable launch.

To provide several launches per year, we often need to make adjustments with our facilities and personnel assigned to manufacturing, testing, and the launches themselves. We can also modify our schedules if the manufacture of a launch vehicle or satellite is delayed for any reason. Once the customer's satellite is delivered to the JAXA Tanegashima Space Center, we support work on the satellite side and coordinate the interfaces between the satellite and launch vehicle.

- Mission Integration

- Every customer's satellites are different. To guarantee a reliable launch, we first identify the specifications for the size and mass of the satellite, the target orbit, the launch date, and hundreds of other conditions and requirements. In the mission integration phase, we consider the hardware and software specifications for the launch vehicle and make technological adjustments.

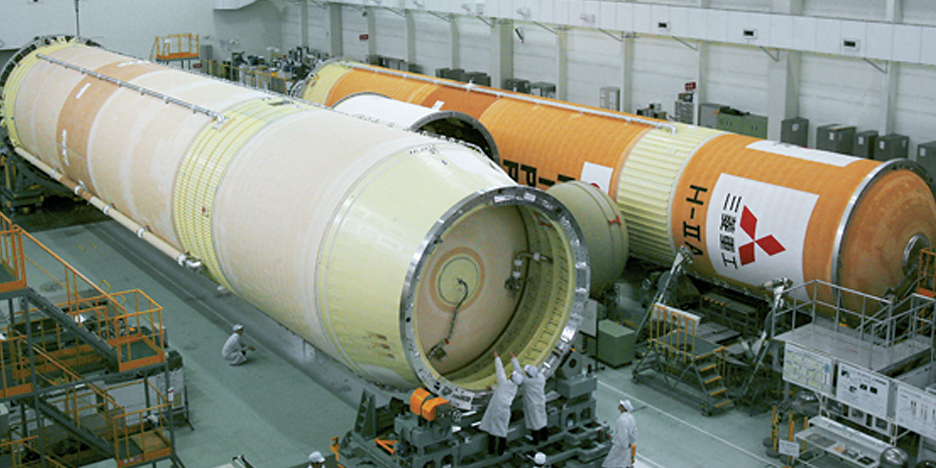

- Launch Vehicle Manufacturing

- MHI manufactures launch vehicles according to the requirements identified during mission integration. Once we actually start building the launch vehicle, we conduct repeated reviews and tests to evaluate conformance with the design objectives and quality requirements.

To ensure the ongoing success of MHI Launch Services, MHI performs repeated quality evaluations for every flight. The personnel handling the inspections are independent from the engineers engaged in routine design, manufacturing, and quality assurance. Specialized design supervisors oversee the propulsion system, electrical system, and other launch vehicle systems to confirm that that the technological requirements are met for all processes from manufacturing onward. They complete their work independently and collaboratively from a cross-sectoral approach to confirm that every H-IIA system is ready for launch. The process continues from the first stage, the manufacture of H-IIA Test Flight No.1, and new results and viewpoints on different themes are collected for each flight.

- Mission Modification

- Once mated with the payload adapter, the component linking it with the launch vehicle, the customer's satellite is encapsulated in the payload fairing and the head of the launch vehicle is put into place. In the mission modification phase, we select and prepare a payload adapter and payload fairing compatible with the satellite to be launched. In some cases, we need to prepare more than one payload adapter and payload fairing for a satellite of a certain size or with certain specifications. Hundreds of the preparations necessary to avoid launch troubles depend on the satellite specifications--tasks as routine as identification of the door position for maintenance work on the payload fairing.

- Launch Operations

- Our unit is responsible for controlling and overseeing the actual launches. On launch day we complete our final checks on the status of the satellite, the launch vehicle, the weather, and the preparations and progress for tracking control and range safety/control operations handled by JAXA. Then we make the final decision on whether to go ahead with the launch.

Work Flow to Launch

The launch services contract with the customer is concluded about two years in advance from the launch. While most of the processes proceed according to the contract schedule, the manufacture of some of the launch vehicle components actually starts before the contract is signed. Once the contract is finalized we conduct various analyses, assemble the vehicle and perform engine firing tests according to the satellite manufacturing schedule. The launch takes place after the final functional test have been completed.

Factory Operations

Parts and subcomponents manufactured by Mitsubishi Heavy Industries and related manufacturers are sent to Nagoya Aerospace Systems Works. The first and second stage liquid rocket engines, the core components of the launch vehicle are manufactured by Nagoya Guidance and Propulsion Systems Works. When necessary, cracks may be checked by nondestructive tests. Once the first and second stages are assembled, electrical and functional tests are performed to confirm that electrical signals properly get through, that the engine nozzle (fuel gas outlet) works as instructed, and that radio waves are properly transmitted and properly received by antenna. Next, after the pre-shipment review, the launch vehicle is shipped to the launch site. This usually takes place about eighteen months in advance of the launch.

Launch Site Operations

When the launch vehicle is transported to the launch site, the first stage, second stage, and solid rocket boosters are joined together, or mated. Then comes an overall system check and a final evaluation of the launch vehicle. Meanwhile, the satellite is transported to the spacecraft test and assembly building at the launch site and separately inspected. When the preparations for loading onto the launch vehicle are complete, the satellite is delivered to us for mating with the satellite separation system and encapsulation in the payload fairing. The launch vehicle and satellite are then mated.

Once the satellite is mated with the launch vehicle, we begin preparing for the final countdown. This starts with a check to ensure that all signals between the satellite and launch vehicle are functioning correctly. After a final check by our review board three days before launch, the countdown commences. After the launch, we report the results to the customer in a post-launch meeting.