Press Information

MHI to Construct Gas Turbine Rotor Production Shop

At Manufacturing Plant in Georgia

-- Targeting Sales Expansion in U.S. GTCC Market, Currency Exchange Risk Hedging --

At Manufacturing Plant in Georgia

-- Targeting Sales Expansion in U.S. GTCC Market, Currency Exchange Risk Hedging --

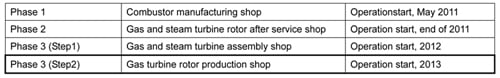

Tokyo, December 14, 2011 - Mitsubishi Heavy Industries, Ltd. (MHI) will soon start construction of the production shop for rotors, the core component of gas turbines, in Pooler, Georgia, near Savannah. Plans call for the commencement of construction in the second quarter of 2012 and completion in the third quarter of 2013. The rotor production shop will be built on the premises of MHI's Savannah Machinery Works, dedicated to gas turbine combustor production, gas and steam turbine rotor after service, and gas and steam turbine assembly. With this plant MHI looks to further expand its power systems business in North America, where gas turbine combined-cycle (GTCC) power generation systems demand is expected to increase sharply, while simultaneously avoiding adverse effects from exchange rate fluctuations.

![[MPSA Savannah Machinery Works site]](/sites/g/files/jwhtju111/files/styles/original_image_style/public/news/image/2011/12/14/1.JPG?itok=-Jjolmdl)

Besides the combustor manufacturing shop which had been into full-scale operation this spring, gas and steam turbine rotor after service shop and gas and steam turbine assembly shop have been under construction since April 2010 and April 2011 respectively. Through this series of investments, including the forthcoming rotor manufacturing shop, MHI looks to enhance its US base structure incrementally: commencing with the manufacture of gas and steam turbine core components and main unit assembly, followed by the provision of a wide range of maintenance and upgrading services for gas and steam turbines, including rotors and other major components. Plans also call for the provision of after-sale services for nuclear power generation plant components. With these initiatives MHI aims to boost its presence in the expanding North American market.

Today the U.S. is in need of securing new power generation sources to replace the country's aged coal-fired thermal power plants. Meanwhile, natural gas prices are stable at low levels - an outgrowth of advancements in technology to extract shale gas, which is abundant in the U.S.- and demand is increasing for power sources to compensate for power supply fluctuations associated with expanding use of renewable energies. Together these developments have spurred interest in GTCC systems, and the launch of the new Savannah Machinery Works is MHI's response to these emerging trends in the U.S. market.

In GTCC plants, a gas turbine and steam turbine are used in combination to generate electric power in two stages, utilizing high-temperature exhaust gas from the gas turbine to produce steam to drive the steam turbine. This configuration enables GTCC plants to achieve higher thermal efficiency, which in turn reduces fuel consumption and results in lower emissions of carbon dioxide (CO2) relative to electricity generation, thereby contributing to environmental protection. Global demand for GTCC power generation plants has been rising in view of their efficient use of fossil fuels and reduced burden on the environment.

MHI is seeking to promote increased adoption of GTCC power generation systems globally, and also aspires to realize its target of a 30% share of the world gas turbine market. Plant constructions and further enhancements at the Savannah Machinery Works are of core strategic importance to the achievement of these goals.

Once its dual (Japan-US) manufacturing scheme is in place, MHI intends to further strengthen its marketing activities for natural-gas-fired GTCC power generation systems - systems that simultaneously achieve effective utilization of energy resources and lighten environmental burdens - not only in North, Central and South America but worldwide.

[MHI G Class Gas Turbine Roter]

[Plant Construction Schedule]

Products Page

About MHI Group

Mitsubishi Heavy Industries (MHI) Group is one of the world’s leading industrial groups, spanning energy, smart infrastructure, industrial machinery, aerospace and defense. MHI Group combines cutting-edge technology with deep experience to deliver innovative, integrated solutions that help to realize a carbon neutral world, improve the quality of life and ensure a safer world. For more information, please visit www.mhi.com or follow our insights and stories on spectra.mhi.com.