Press Information

Completely Rewrite Industry’s Understanding of Transmitting High Quality Laser Processing Light over Long Distances

-Innovation in Laser Processing Technology for Social Infrastructure Products by Optical Fiber Technology for Information and Communication-

-Innovation in Laser Processing Technology for Social Infrastructure Products by Optical Fiber Technology for Information and Communication-

Mitsubishi Heavy Industries, Ltd.

Nippon Telegraph and Telephone Corporation (NTT, Chiyoda-ku, Tokyo, President and CEO: Hiroo Unoura), and Mitsubishi Heavy Industries, LTD (MHI, Minato-ku, Tokyo, President and CEO: Shunichi Miyanaga) entered into a cooperative agreement in April 2014 to create new values by applying NTT's research & development (R&D) results in the area of information and communication technology (ICT) to MHI's social infrastructure products in fields such as energy, environment and transportation, as well as plant sites in Japan and other countries*1.

NTT and MHI have demonstrated kW class high power single-mode laser transmission over several-ten to several-hundred meters by harmonizing NTT's photonic crystal fiber (PCF) technology and MHI's high power laser processing technology. Maximum transmission distance of over 1 kW single-mode laser light is limited around only 10 m at present. Our achievement enables to transmit the high power single-mode laser light several to several-ten time longer distance.

Laser processing technology is being used in various social infrastructure products, e.g. vehicles, airplanes, and so on, as an efficient method for cutting, hole forming, welding etc., and its application field is expected to increase almost with limit. Our achievement enables us to transmit high power single-mode laser light for distances greater than is thought possible while retaining the light's quality to yield high accuracy laser processing sources. The result is a key technology for accelerating the application area expansion of laser processing technology and for fostering further innovation in social infrastructure products.

This achievement will be reported at the 89th lecture of Japan Laser Processing Society*2 which will be held at Suita Campus, Osaka University at 23-24 May 2018.

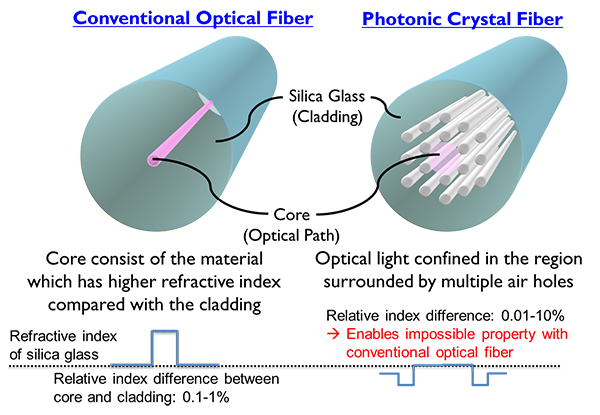

Figure 1 Image of conventional optical fiber and photonic crystal fiber (PCF).

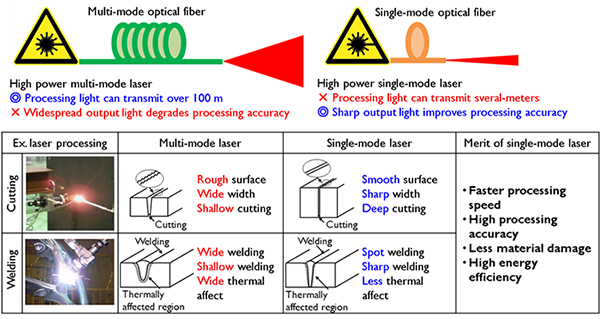

Optical fiber is being widely used all over the world as a key component of today's information and communication society. It can be also used in variety of application areas other than telecommunication, e.g. endoscope, gyroscope, medium to transfer laser processing light, and so on. Laser processing requires the transmission of lights whose powers are more 10000 times larger than that of conventional telecommunication light. However, maximizing the optical power and transmission distance encounters the physical limit created by optical nonlinearity*3. Conventional laser light (multi-mode laser light)*4, can be transmitted over 100 m of existing multi-mode fiber. Unfortunately, multi-mode laser light is not appropriate for laser processing as extremely precise processing accuracy is essential. While single-mode laser light offers 10 kW class powers and high quality, both suitable for accurate laser processing, transmission distance is limited to several meters if existing single-mode fiber is used. A new transmission medium is needed.

NTT has been conducting R&D into photonic crystal fiber (PCF), which transmits light by using the confinement effect of air holes. PCF consists of silica glass and multiple air holes, and offers novel properties impossible with conventional optical fiber. PCF enables us to realize precise refractive index control in the cross section of the optical fiber by designing the diameter and/or pitch of air holes. Based on extensive research, NTT proposes a novel PCF suitable for high power single-mode laser transmission, and an optimum design for the PCF. NTT and MHI have proved the high power transmission potential of the PCF proposal experimentally.

[Summary of Achievements]

In this achievement, NTT and MHI

- - Overcome the transmission optical power and distance limitations by employing PCF,

- - Realize superior high power transmission performance and feasible optical fiber productivity simultaneously by proposing a novel cross sectional hole arrangement.

These key advances enable us to design a PCF with four-times higher high power transmission potential than existing single-mode fiber for high power single-mode laser transmission. Moreover, NTT and MHI

- - Successfully demonstrated 10 kW-30 m and 1 kW-300 m transmission using a high power single-mode laser light source and a fabricated PCF.

This achievement expands the application area of high power single-mode laser processing technology, and is expected to rewrite our concept of various social infrastructures products.

[Details of Achievements]

1. Deployment of PCF (Feature of PCF)

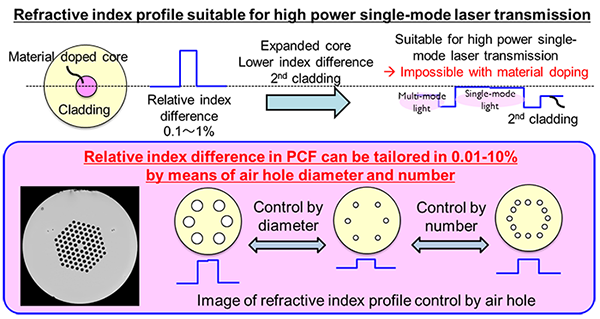

The optical fiber used to connect the high power single-mode laser light source set in strictly-controlled environments to arbitrary processing sites must offer high output quality. However, the optical power and distance in an optical fiber is limited by optical nonlinearity*3. Maximum transmissible optical power of an optical fiber can be increased by

- - Expanding the core area, as it acts as the optical light path,

- - Decreasing the refractive index difference between core and cladding,

- - Filtering unwanted light propagation components (multi-mode light) to maintain processing accuracy.

However, these requirements demand extremely precise refractive index control, of the order of 0.01%, which is impossible with conventional optical fiber as it creates the core by material doping.

PCF, on the other hand, confines the light to a region delineated by an array of air holes. The effective refractive index of the air hole array can be set arbitrarily by altering diameter d and number (alternatively pitch Λ) of the air holes. Thus, the cross sectional refractive index of a PCF can be designed precisely to the order of 0.01-10%. This superior control of refractive index enables us to realize single-mode transmission at arbitrary wavelengths. NTT has successfully developed low loss PCF for realizing large capacity transmission at arbitrary wavelengths*5. Moreover, NTT created an optical fiber cord that can be used even if bent at 180 degrees without any optical signal degradation by combining the strong confinement effect of air holes with conventional optical fiber*6. As a result, NTT and MHI have succeeded in transmitting high power single-mode laser light to remote processing sites with no quality degradation by employing the superior refractive index control offered by PCF.

Figure 2 Basic concept for improving the high power transmission potential in an optical fiber and applicability of PCF

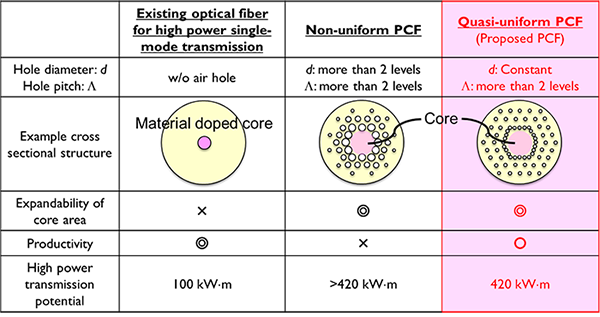

2. Novel Quasi-uniform PCF and its Optimization

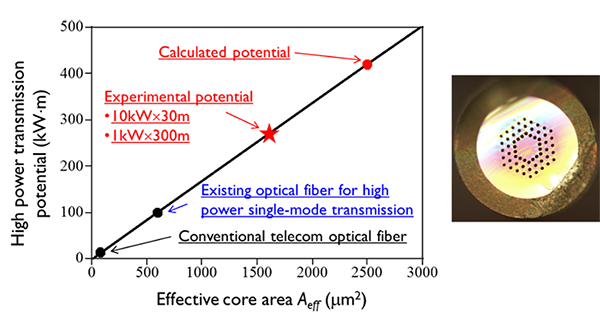

As mentioned above, the transmission properties of PCF can be precisely controlled by setting the diameter d and pitch Λ of air holes. Further improvement is possible by combining multiple d and Λ values for designing the cross sectional air hole arrangement. However, the complex cross sectional design severely degrades the fabrication productivity of optical fiber. To eliminate this issue we developed, for the first time, the quasi-uniform PCF; it has constant d but Λ is varied. This enables us to expand the effective core area while ensuring feasible levels of productivity. Moreover, we numerically clarified that by optimizing the values of d and Λ, the proposed quasi-uniform PCF can achieve 420 kW-m high power single-mode transmission. Power of this level, 420 kW-m, is four-times larger than that of existing optical fiber.

Figure 3 Image and feature of quasi-uniform

3. High Power Single-Mode Transmission Experiments

A 30 m long quasi-uniform PCF was fabricated based on the design guideline described in Section 2. The output of a 10 kW single-mode laser light source was successfully transmitted over 30 m, and experiments confirmed its high power transmission potential of 270 kWm. Similarly, a 1 kW single-mode laser light was transmitted over 300 m, and which corresponds to the high power transmission potential of 300 kW-m.

Figure 4 High power transmission potential of quasi-uniform PCF (left) and cross sectional photo of fabricated quasi-uniform PCF (right).

[Future Prospects]

The achievements described herein enable us to expand the transmission distance of high power single-mode laser light from several meters to several hundreds of meters. Such performance destroys the limits currently deemed inevitable in the laser processing field and thus improves the effective use of high power single-mode laser sources. The application of single-mode lasers not only improves the cutting and hole forming accuracy, but also reduces processing time by using the laser energy more effectively.

This achievement can be used to implement remote processing, remote welding and thick plate cutting in the existing manufacturing processes of vehicles, airplanes, marine vessels, and so on. The achievement is expected to trigger rapid expansion in the application area of laser processing technology to an extremely wide variety of social infrastructure products, and greater innovations in manufacturing.

MHI will develop applications focused on hole forming and the welding of heat-resisting alloy, with the aim of realizing practical deployment by 2019.

[Glossary]

*1 Press release: NTT and MHI Conclude Tie-up Agreement in R&D Integrating Social Infrastructure and ICT

*2 The 89th lecture, Japan Laser Processing Society

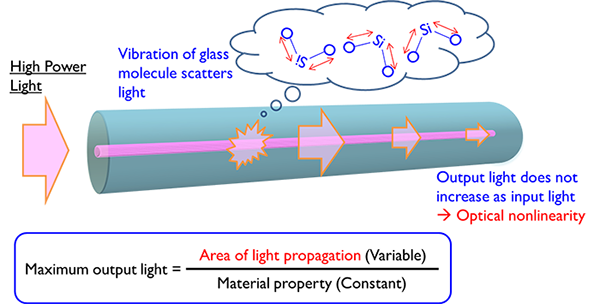

*3 Optical nonlinearity

Glass molecular vibration caused by high power light scatters optical signal. This results in output light saturation; power does not increase even if we increase the input light. Maximum transmission optical power in an optical fiber is proportional to core area (effective optical path) and inversely proportional to material property. Although the material property is constant, we can design and control the core area. Thus, the maximum transmission power can be increased by expanding the core area of the optical fiber.

Figure 5 Image of output optical power limitation caused by glass molecule vibration.

*4 Laser light and processing quality

Multi-mode laser is not suitable for accurate laser processing since the output light from an optical fiber spreads far too widely. Single-mode laser is suitable for accurate laser processing since the output light from an optical fiber remains tightly collimated, however, high power single-mode laser light can travel only several meters if existing single-mode fiber is used. Thus, laser processing requires a novel single-mode fiber that can transmit high power single-mode laser light over several tens of meters.

Figure 6 Image of laser quality and transmission distance (top) and processing accuracy (bottom).

*5 New breed of optical fiber, "Holey Fiber", shows strong prospects for application

*6 NTT Develops Optical fiber Cord that can be easily bent, folded, and tied, and enables easy connections

About MHI Group

Mitsubishi Heavy Industries (MHI) Group is one of the world’s leading industrial groups, spanning energy, smart infrastructure, industrial machinery, aerospace and defense. MHI Group combines cutting-edge technology with deep experience to deliver innovative, integrated solutions that help to realize a carbon neutral world, improve the quality of life and ensure a safer world. For more information, please visit www.mhi.com or follow our insights and stories on spectra.mhi.com.