Press Information

Success Achieved in “Next-Generation Oilless Cryogenic ORC Turbine Generator” Operation by Liquid Nitrogen

-- Hermetic Oilless Structure of Turbine for ORC Generation Applied to Cryogenic Power Generation --

-- Hermetic Oilless Structure of Turbine for ORC Generation Applied to Cryogenic Power Generation --

・ Innovation results in higher reliability, space savings and maintenance-free operation compared to conventional turbine structure used in LNG cryogenic power generation

・ Demonstration testing used liquid nitrogen as substitute for LNG as cryogenic energy, verify stable operation under cryogenic environment successfully

・ Innovation will lead to more stability and higher reliability of LNG cryogenic power generation systems and application in future hydrogen cryogenic power generation

Tokyo, February 28, 2023 – Mitsubishi Heavy Industries, Ltd. (MHI) and Mitsubishi Heavy Industries Marine Machinery and Equipment Co., Ltd. (MHI-MME), a wholly owned operating company of MHI based in Nagasaki, have successfully conducted demonstration testing of 100kW class cryogenic ORC (Organic Rankine Cycle) power generation using the world’s first “next-generation oilless cryogenic turbine generator.” The innovative generator adapts the turbine generator featuring a hermetically sealed oilless structure, of the kind used in ORC generation, to cryogenic power generation(Note1). The testing demonstrated that with use of liquid nitrogen as the cryogenic energy source it is possible to secure a stable refrigerant cycle and the specified regeneration output without freezing-induced clogging, etc. even under conditions more severe than the low temperatures of conventional LNG (liquefied natural gas) cryogenic generation.

The new ORC turbine generator, developed in-house applying MHI Group’s comprehensive turbine and cryo-temperature technologies, adopts oilless magnetic bearings and a hermetically sealed structure that prevents refrigerant leakage outside the system. Improvements for refrigerant power generation were made based on the Company’s operating track record in ORC power generation, enabling higher reliability, space savings and maintenance-free operation compared to the turbine structure used in earlier LNG-cooled power generation (steam turbines with open-end type, featuring forced-lubricated sleeve bearings).

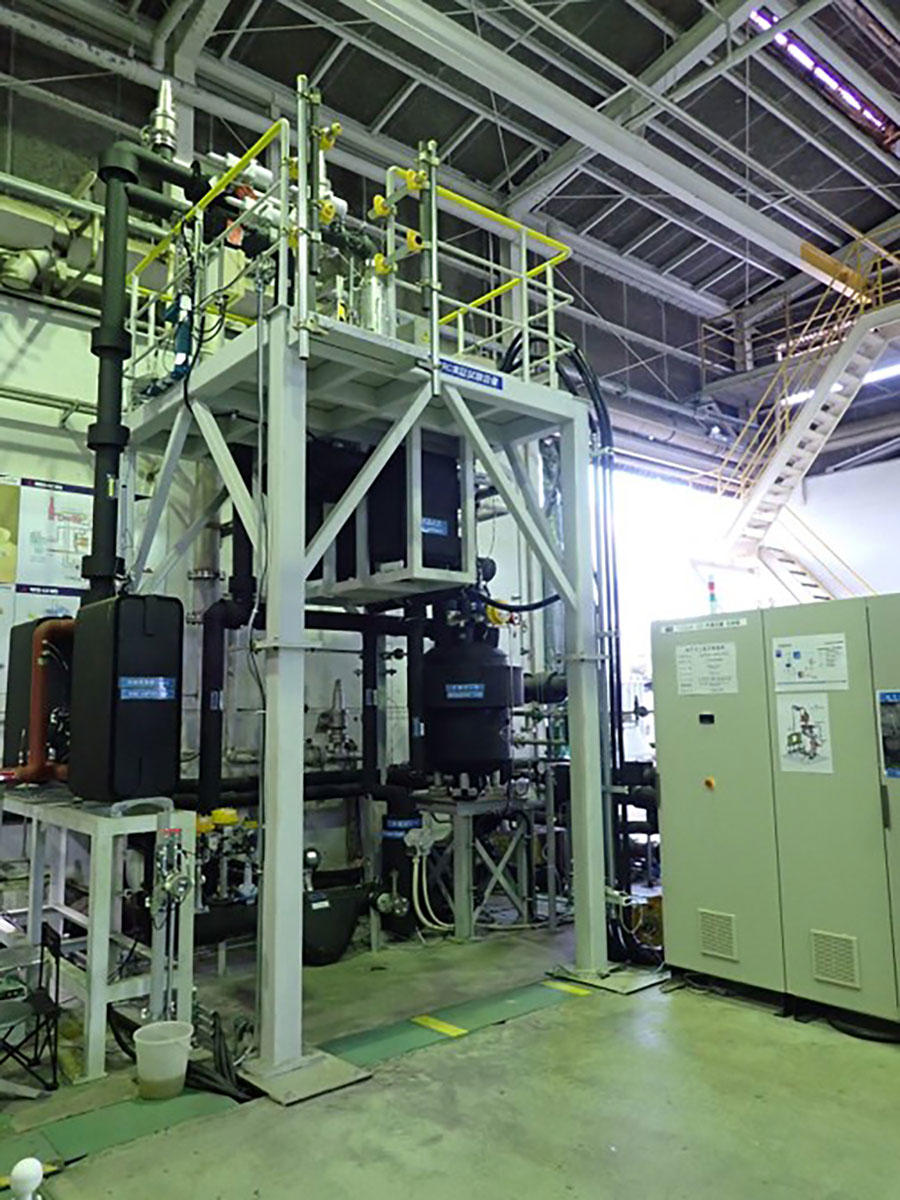

In the demonstration testing, which was conducted in January 2023 at MHI’s Research & Innovation Center in the Nagasaki District, cryogenic power generation was performed by an intermediate fluid using a Rankine Cycle using cryogenic energy. Besides using liquid nitrogen (boiling point: approx.-196℃) in place of the conventionally adopted LNG (boiling point: -160℃), the test simulated actual LNG vaporization equipment such as a marine FGSS (fuel gas supply system) and offshore/onshore LNG vaporization equipment. The testing provided useful results in terms of understanding the refrigerant cycle properties and the phase changes(Note2) of cryo-temperature media such as LNG or liquid nitrogen, and also confirmed the system’s controllability. These results suggest the potential for further stabilization and reliability in LNG refrigerant generation systems, and also support expectations of the use of hydrogen (boiling point: approx. -253℃), seen as a promising decarbonized fuel, for cryogenic power generation.

MHI Group is currently strengthening its position in the Energy Transition, and development of a next-generation turbine generator by MHI and MHI-MME will contribute to the creation of new power generation business making effective use of unused refrigeration heat and waste heat. Going forward, as a leading company in the field of decarbonization, MHI Group will pursue further development of solutions that will contribute to reduction of greenhouse gas emissions and protection of the environment.

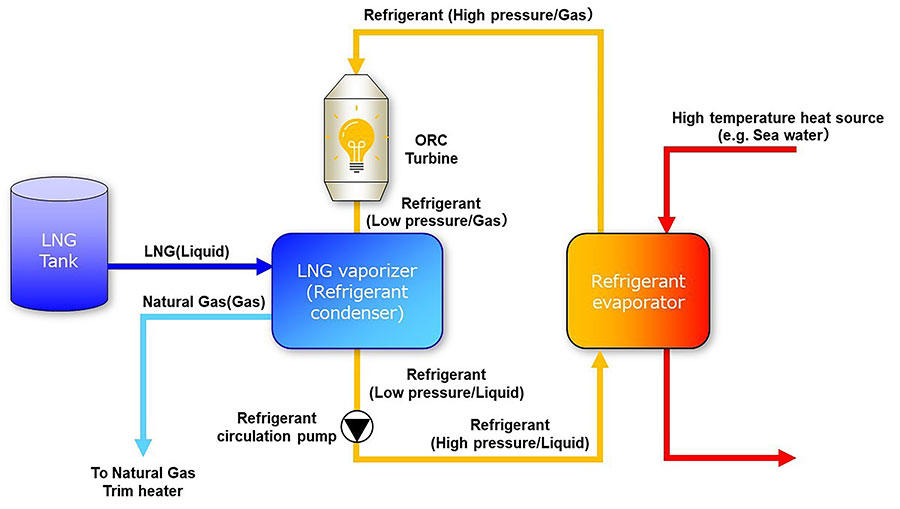

- 1Cryogenic power generation is the generator rotates by extracting torque from the energy derived from the temperature differential with lower-than-normal temperatures. Power is generated by rotating a turbine by cooling the intermediate heating medium (refrigerant) of LNG’s to below -160℃, raising the temperature and vaporizing the intermediate heating medium using seawater, etc., and utilizing the resulting high-pressure steam as the rotational force. As a clean power generation method that reduces CO2, it is re-attracted as LNG demand increases.

- 2Phase changes are changes in the three states (phases) of material substances: for example, from liquid to vapor.

100kW class cryogenic ORC power generation demonstration testing equipment

Next-generation oilless cryogenic ORC turbine generator

Cryogenic ORC power generation system in LNG vaporization plant

About MHI Group

Mitsubishi Heavy Industries (MHI) Group is one of the world’s leading industrial groups, spanning energy, smart infrastructure, industrial machinery, aerospace and defense. MHI Group combines cutting-edge technology with deep experience to deliver innovative, integrated solutions that help to realize a carbon neutral world, improve the quality of life and ensure a safer world. For more information, please visit www.mhi.com or follow our insights and stories on spectra.mhi.com.